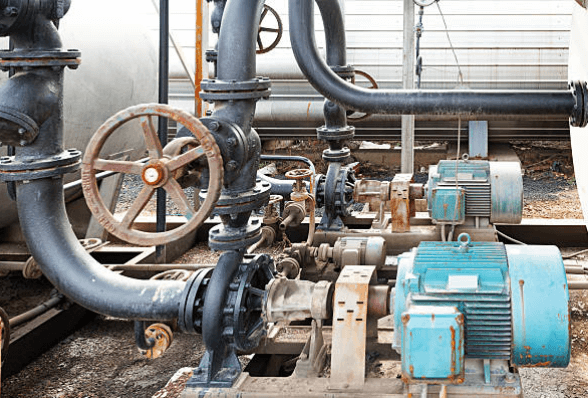

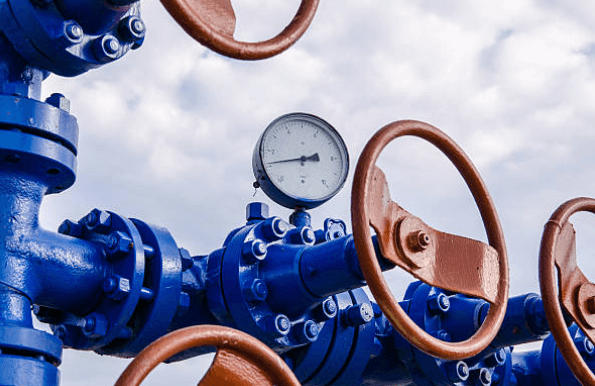

From water systems to power plants, valves are a critical part of the infrastructure of underground systems. While the fundamental purpose of all valves is the same, their design and construction vary depending on the specific application. Have you ever wondered what the best type of valve to use during an underground construction project is? Varying systems require different types of valves, but how do you know which one is right for your project?

Determining which valve would be the right requires considering numerous factors, such as the type, material used, purpose, and pressure rating. It is also important to make your purchase from a reliable industrial valve manufacturer to get quality assurance.

Read this blog to explore different types of valves used in underground systems and how they can be utilized for various roles.

What Are Underground Valves

An underground valve is a key infrastructure component in urban water supply systems. Its primary function is to control and distribute water from the main supply line to the various end-user connections. The valves are also used to regulate pressure and flow in the system and to isolate sections of the network for maintenance or repair work.

Why Valve Plays An Important Role In Underground

Valve plays an essential role in underground mining operations. Without a valve, the mining process would be significantly more difficult, if not impossible. Here are some of the reasons why the valve is so important in underground mining:

Regulate Water Flow:

A valve controls the flow of water in and out of the mine. This is critical for maintaining a safe and consistent work environment underground. If too much water were to enter the mine, it could cause a collapse. And if not enough water were flowing out of the mine, it could lead to serious health hazards for the miners.

Regulate Ventilation:

The valve also helps control ventilation in the mine. Proper ventilation is essential for keeping the air quality safe for miners to breathe. Without adequate ventilation, dangerous gases could build up underground and cause serious health problems for miners.

Maintain Pressure:

The valve helps regulate the pressure in the mine. High pressure can be extremely dangerous in an underground mining environment. It can cause cave-ins and other disasters. By controlling the pressure with a valve, miners can help prevent these accidents from happening.

Types Of Underground Valves Based On Their Design

When it comes to design, there are various types of underground valves that are used for a specific purpose. Read below to find out about different types of underground water valves.

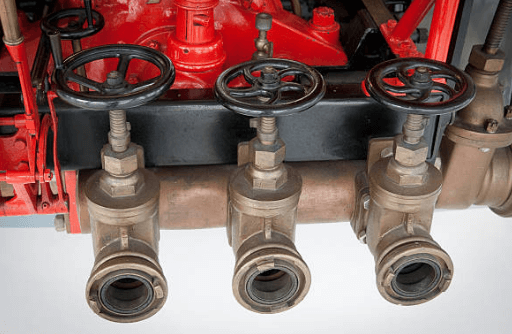

Gate Valves

Gate valves are used in a variety of industries, but they are particularly well suited for use in the underground mining industry. Gate valves underground allow for a very tight seal, which is essential in preventing the escape of potentially harmful gases and liquids. They are also very durable and can withstand the high pressures that are often present in underground mining operations.

Globe Valves

Valves play an essential role in the underground industry, and globe valves are one type that is commonly used. Globe valves are designed to regulate fluid flow by controlling the opening and closing of a passageway. They consist of a round body with a stem that goes through the center. The stem controls a disk that is connected to the body. When the stem is turned, the disk opens or closes, which allows or restricts flow.

Globe valves are well-suited for use in the underground industry because they can withstand high pressures and temperatures. They are also able to handle abrasive materials, making them ideal for controlling the flow of slurry, mud, and other liquids used in mining operations. In addition, globe valves can be placed in tight spaces due to their compact design.

Globe valves continue to be widely used in the underground industry due to their durability and reliability. When properly installed and maintained, they can provide years of trouble-free service.

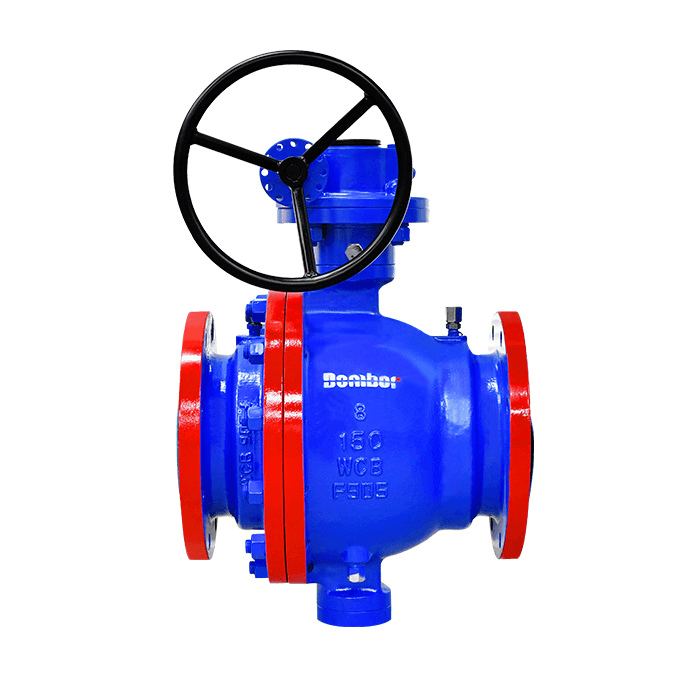

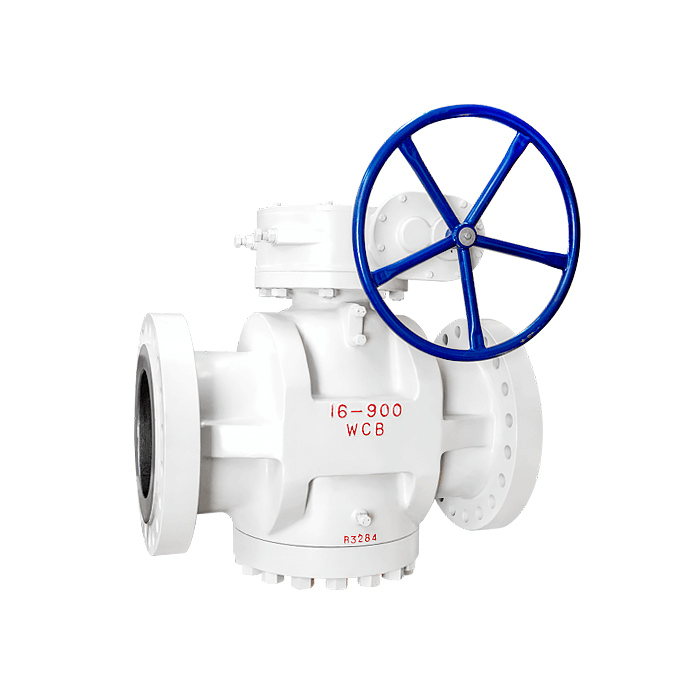

Industrial Ball Valves

Industrial ball valves are essential for many industries, including the underground mining industry. They are used to control the flow of liquids and gases and can be employed in a wide variety of settings. Ball valves are characterized by their spherical shape, which allows for a very tight seal. Industrial ball valve manufacturer uses top steel material to make ball valves. This makes them ideal for use in situations where a high degree of precision is required.

Industrial ball valves are often used in conjunction with other types of valves, such as gate valves or butterfly valves. This allows for greater flexibility and control over the flow of liquids and gases. In some cases, ball valves may be used as part of a larger system that also includes pumps and other types of equipment.

The underground mining industry relies heavily on ball valves to ensure the safe and efficient operation of its facilities. Ball valves are used to control the flow of air, water, and other fluids in mines. They are also used to regulate the pressure and temperature of these fluids. Ball valves play a vital role in the underground mining industry, and their use is likely to continue to grow in the future. You can contact a trustedtrunnion ball valve manufacturer to get premium-quality and highly sustainable trunnion ball valves.

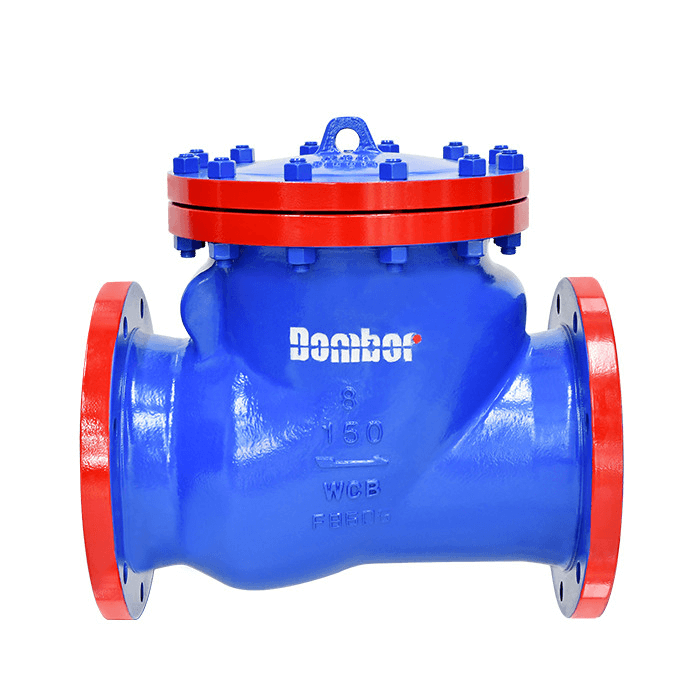

Check Valves

Check valves are designed to allow fluid to flow in only one direction and prevent backflow. Underground pipe valveis commonly used in pipeline transport systems to keep water, oil, and other liquids from flowing backward and causing damage or contamination. Check valves are also used in sewage and drainage systems to prevent flooding and backups.

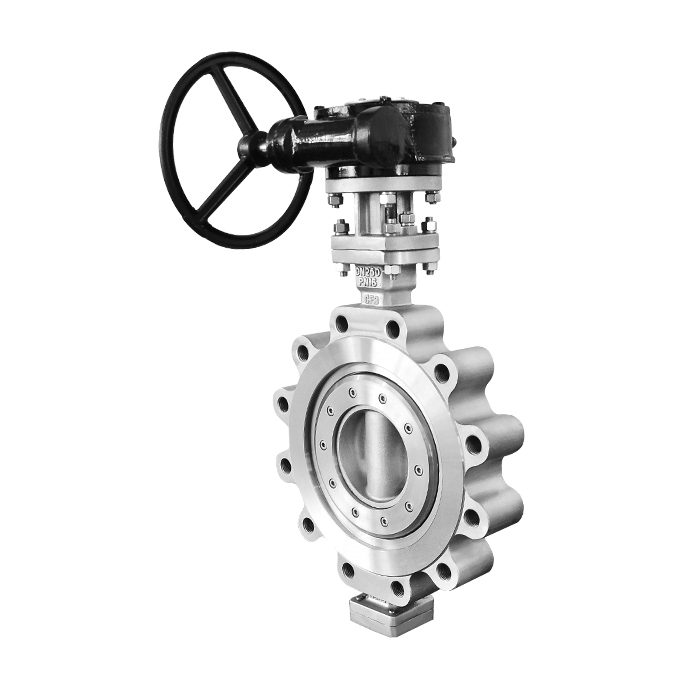

Butterfly Valves

A butterfly valve is commonly used in underground industry applications. Their design allows for easy installation and maintenance and offers reliable performance in a wide range of operating conditions. High-performance butterfly valves can be used in both onshore and offshore applications, and their versatility makes them an ideal choice for many industrial installations. There are many kinds of butterfly valves, such as lug type butterfly valve, wafer butterfly valves, and concentric butterfly valves available on the market.

Safety Valves

Safety valves are essential to any underground industry, as they help to protect workers and equipment from potential hazards. Many types of safety valves are available, each designed for specific applications. Some of the most common safety valves used in underground industries include:

Relief Valves:

These valves are designed to relieve pressure build-up in a system, preventing it from becoming dangerous.

Pressure Reducing Valves:

These valves are used to reduce the pressure of a fluid or gas before it enters a system, helping to prevent damage to equipment or injuries to workers.

Backflow Prevention Valves:

These valves help to prevent fluids or gases from flowing back into a system, which can cause damage or accidents.

Using the right type of safety valve for the specific application is essential to ensure maximum protection for workers and equipment.

Plug Valves

Plug valves are used extensively in the underground mining industry. They are classified as quarter-turn valves and are used to control the flow of fluid in a pipeline transport system. Plug valves have a cylindrical body with a hole drilled through the center. A plug, which is slightly smaller in diameter than the body, is inserted into the body and rotates to open and close the valve.

Plug valves are very versatile and can be used for a variety of applications. They are commonly used to isolate sections of pipelines, regulate flow, and act as shut-off valves. Plug valves are available in a wide range of sizes and materials to suit different applications.

There are many benefits to using plug valves in underground mining operations. They are easy to operate and require little maintenance. Plug valves are also very durable and can withstand harsh conditions.

Pinch Valves

In underground mining and tunneling operations, pinch valves are an essential part of the equipment used to control the flow of materials. These valves are designed to provide a reliable seal in even the most difficult operating conditions, and their rugged construction makes them ideal for use in these demanding applications.

Pinch valves are actuated by means of a lever or handle that is connected to the valve body. This allows the operator to apply a force to the valve seat, which in turn seals off the flow of material through the valve. Pinch valves are well suited for use in abrasive environments, as they can withstand heavy wear and tear.

Pinch valves are available in a variety of sizes and configurations, making them suitable for use in a wide range of applications. In addition, they can be fitted with a variety of accessories, such as position indicators and limit switches, which make them even more versatile.

Materials Used In Making Underground Valves

Underground valves are designed using various kinds of materials. When it comes to choosing the right type of valve, the material used is an essential factor to be taken into consideration. Read below to find out about the various types of materials used in making underground valves.

Stainless Steel:

Stainless steel is an ideal material for making underground valves due to its durability and resistance to corrosion. Stainless steel valves can withstand the harsh conditions found underground, where they are exposed to high temperatures and pressures. Thanks to their superior strength, stainless steel valves can also be used in applications where other materials would fail.

Cast Steel:

Cast steel is a popular material choice for underground valves due to its high strength and resistance to wear and tear. This makes it ideal for use in demanding environments where valves are subject to heavy loads and high pressures. Cast steel is also resistant to corrosion, making it an ideal choice for use in corrosive environments.

Forged Steel:

Underground valves are commonly used in a variety of applications, including water and sewage treatment, oil and gas pipelines, and power generation. Forged steel is often used to create these valves due to its durability and strength. The manufacturing process of forged steel involves heating the material to high temperatures and then shaping it into the desired shape. This results in a valve that is able to withstand a great deal of pressure and can be used in a wide range of settings.

Components Of Underground Valves

The components of an underground valve are listed below. Read further to find out.

Main Body:

The main body of an underground valve is typically made of cast iron, ductile iron, or steel. It is essential that the material used for the main body is resistant to corrosion, as this will help to ensure the longevity of the valve. The body of the valve is also usually coated with a layer of epoxy resin or another type of protective coating to further reduce the risk of corrosion.

Bonnet

The bonnet of an underground valve is a key component in the overall function of the valve. The bonnet helps to seal the valve and keep contaminants out of the interior of the valve. Additionally, the bonnet helps to protect the internal components of the valve from damage.

Ports

The ports of an underground valve are responsible for the flow of fluids and gases in and out of the device. There are typically two or three ports, depending on the size and type of valve. The inlet port is where fluids or gases enter the valve, and the outlet port is where they exit. The third port, if present, is called the vent port and is used to relieve pressure inside the valve.

Actuator

An underground valve is a type of valve that is installed below ground level. The actuator is the component of the valve that controls the opening and closing of the valve. There are many different types of actuators, but the most common type used in underground valves is the hydraulic actuator.

Hydraulic actuators use fluid pressure to open or close the valve. They are often used in high-pressure applications because they can generate a large amount of force. Hydraulic actuators are also very durable and reliable, making them ideal for use in underground valves.

Disc

Discs are an essential component of many valves, particularly underground valves. Made from tough and durable materials, discs are designed to withstand the high pressures and temperatures that are common in underground environments. A well-designed disc will provide years of trouble-free operation.

There are several things to consider when choosing the right disc for an underground valve. First, the material must be compatible with the fluid being controlled. Second, the disc must be able to withstand the temperatures and pressures that will be present in the system. Third, the geometry of the disc must be appropriate for the application. Finally, the manufacturer should have a good reputation for quality and reliability.

When it comes to underground valves, discs are a crucial part of ensuring safe and reliable operation. By taking the time to choose the right disc for the application, you can rest assured that the valves will provide years of trouble-free performance.

Seat

A seat in an underground valve is a mechanism that helps to control the flow of water through the valve. It is typically made from materials that can withstand the pressure of water, such as metal or plastic. The seat is usually located at the bottom of the valve, where it can be opened and closed by a handle or lever.

Stem

A stem in an underground valve is a critical component of the valve that helps to regulate water flow. The stem is located at the bottom of the valve and is responsible for opening and closing the valve. In order to open or close the valve, the stem must be turned. The amount of water that is able to flow through the valve is controlled by the position of the stem. If the stem is turned to the left, less water will be able to flow through the valve. If the stem is turned to the right, more water will be able to flow through the valve.

Where Can The Underground Valve Be Used?

Here are a few applications of underground valves. Read below to find out.

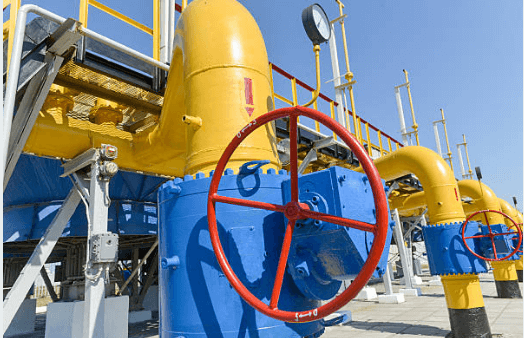

Underground Water Valve

The use of valves as underground water stop valves is an effective way to regulate the flow of water in an area. This type of valve is installed below the ground level and is used to control the water flow by regulating the amount of water that is allowed to pass through it. This can be done by either turning the valve on or off or by adjusting the water valve undergroundto a specific setting. The use of underground valves as an underground water valve can help to prevent flooding and erosion and can also help to conserve water in an area. Hence, they are often used as underground irrigation valve as well.

Underground Gas Valve

Using valves such as an underground gas shut off valve can be an effective method to control the flow of gas in various industries. These valves underground are installed beneath the ground, and they allow to turn the gas off at the main source. This can be very helpful in the event of a gas leak, as it will prevent the gas from continuing to flow into the entire space. It is important to remember, however, the underground stop and waste valvesmust be properly installed and maintained in order to work properly.

Fire Hydrant Underground Valve

There are many reasons why using an underground valve as a fire hydrant is a good idea. For one, they are much less likely to freeze in cold weather. This is because the ground around them helps to insulate them and keep the underground fire hydrant valveat a consistent temperature. Additionally, fire hydrant underground valveis also less likely to be damaged by vehicles or other objects since they are out of the way and not visible. Finally, underground hydrant valve can provide a steadier flow of water than above-ground hydrants since they are not affected by changes in pressure.

ASME, API Standards For Underground Industry

ASME and API standards are essential for the underground industry. They help to ensure safety and quality in the products and services that are provided. ASME is the American Society of Mechanical Engineers, and API is the American Petroleum Institute. Both organizations develop voluntary consensus standards that are used across the globe.

In the underground industry, these standards help to ensure that equipment is safe to use, is sustainable and that it will perform as expected. Adhering to these standards can also help to improve the reputation of a company.

Factors To Consider When Selecting Underground Valves

There are many factors to consider when selecting underground valves for your business. Here are a few of the most important factors to keep in mind.

The Size of the Valve:

The size of the valve is one of the most important factors to consider. It is essential to measure the area where the valve is needed to be installed before making the purchase. If the valve is too small, it may not be able to handle the required flow rate. If it is too large, it may not fit in the space available.

The Type of Valve:

There are two main types of underground valves – gate valves and check valves. Gate valves are typically used for larger applications, while check valves are better suited for smaller applications.

The Material:

Underground valves are available in a variety of materials, including plastic, metal, and concrete. Each material has its own advantages and disadvantages, so it is crucial to choose the right material depending on the needs. For example, different materials have different durability and resistance to corrosion. Make sure to select a valve made from a durable material that will be able to withstand the conditions it will be exposed to.

Pressure Rating:

The pressure rating of the valve. Make sure to select a valve with a pressure rating that matches or exceeds the operating pressure of your system. The industrial valves must also pass through a number of quality inspections to offer quality assurance.

Contact Professional Industrial Valve Manufacturer

Valves are an integral element for underground plumbing systems. Therefore, it is necessary to understand the different types of underground valves to be incorporated for various applications. Likewise, it is equally important to invest in quality underground valves from a trusted industrial valve supplier, considering the extensive choices available in the market. You can contact us to buy premium-quality industrial valves that will perfectly fit your business needs.