Valves play an integral role in a water distribution system. They are responsible for regulating water flow, directing changing, opening and closing water flow. No matter how small these valves may seem, they are responsible for maintaining pressure and supply in the whole distribution system. These small mechanical instruments are much more powerful than they appear.

Valves used in the water distribution system can either be operated manually or can be automated. With rapid technological advancements, manufacturing companies are also introducing remote control or electric valves, which require no manual support. Either way, valves are extremely important mechanical devices used in regulating water flow.

What Is A Water Distribution Valve?

An industrial valve is a powerful mechanical device that is installed in water supply systems to regulate or stop the flow. They control the pressure of water flow and can immediately shut down the system. As the name suggests, a water distribution valve takes care of the distribution of water in both residential and industrial settings.

Valves come in different shapes and sizes, and various types of valves are used in water distribution systems. Each of these types has special features; however, there is one similarity between them all, all water supply valve types are essential for opening, closing or regulating the water supply.

Why Does The Valve Play An Important Role In The Water Distribution System?

A common question asked by most users who are new to valve systems and types. In a water distribution system, a valve plays a significant role in controlling water flow and its pressure. It is because of valves the water supply is safely delivered through pipelines, and the pressure of the flow is in control. Here are the primary reasons why valves are considered so important in a water distribution system:

Pressure Maintenance

If the main water supply source has extreme or very low pressure, a valve takes care of that. Pressure maintenance is one vital role valves play in water distribution systems. For instance, if the pressure of rushing water is extremely high and there are no valves to release air and control the flow, the waterline pipes can burst and cause an accident. In a way, water valves maintain safety as well.

Safety Maintained

Other than water, when industries have to deal with fluids and gasses with extreme temperatures a valve ensures all the safety required to maintain an uninterrupted flow. They are made with durable materials; hence, they do not react with fluids or corrode. During extreme pressure conditions, a valve helps release the pressure and restore a normal flow. Therefore, safety is always maintained.

But, when these valves suddenly fail to function because of the lack of proper maintenance, the safety of the supply line is undoubtedly at stake.

Air Release

Excess pressure can cause a lot of air build-up inside the supply lines of water distribution systems; if the air pressure reaches an extent, it can force the pipelines to crack or, even in a worse scenario, burst. This is why valves are important in water distribution systems; they can help with excess air release and prevent unwanted mishaps.

No Fear Of Backflows

Backflows are a nightmare for both industrial and residential settings. Backflows can contaminate the water supply of the whole distribution system, which is something really scary. But, valves are those little powerful mechanical devices that are capable of preventing backflows and maintaining a hygienic flow in single or multi-direction.

Types Of Valves In Water Distribution Systems Based On Their Design

Not a single type but different types of valves are used in water supply system, and their functions also are other. From their sizes, shapes and special abilities, water distribution valves’ various designs are as follows:

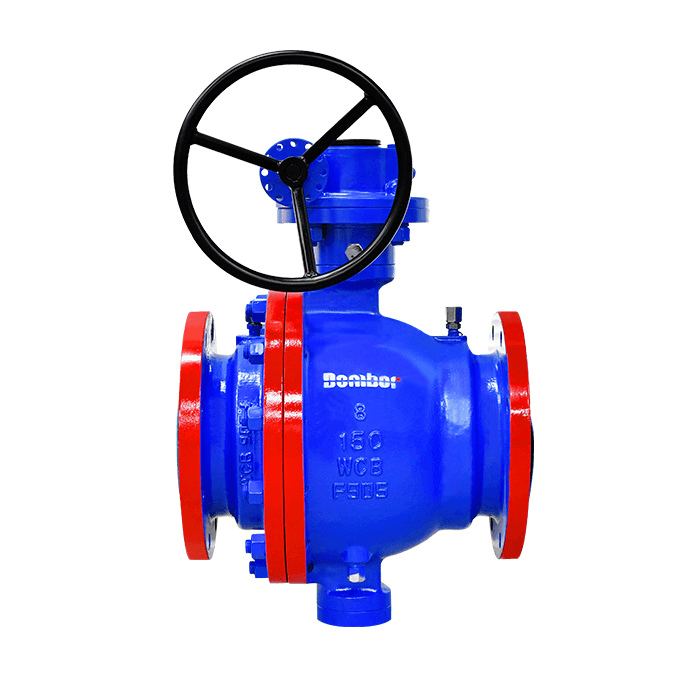

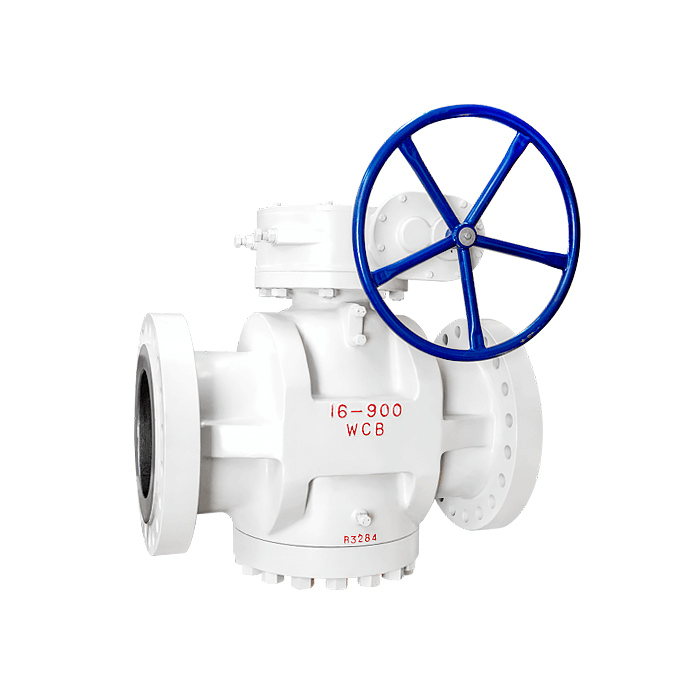

Industrial Ball Valve

Another common type of valve used in water distribution systems is the industrial ball valve. The name of this valve derives from the floating ball that regulates the flow of water. The ball attached internally in this valve can rotate at an angle of 90°. The rotation of the ball can be automatic or manual.

Industrial ball valves for water supply are ideal in settings where there is always an emergency for the immediate cut-off of water supply. The powerful mechanism of ball valves can prevent the flow of water instantly by sealing the pathway. Industrial ball valves are very efficient in throttling and maintaining water pressure. You can also consider a trunnion ball valve manufacturer.

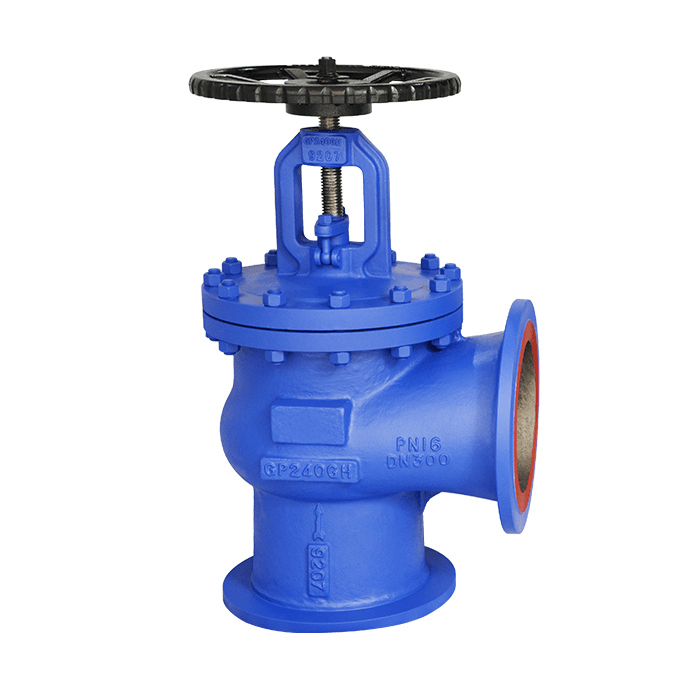

The most common type of water distribution valve is a gate valve with a unique design. Their internal part is attached to tiny wedge-shaped metal gates that are responsible for controlling the water flow or stopping immediately. Gate valves are also sometimes commonly recognized as a shut-off valve because of their ability to cut off the water supply immediately. You can find gate valves in industrial locations or settings requiring sudden water flow cut-off. The mechanism of a gate valve resembles that of a dam that controls the flow of a river.

They may seem little compared to the large water distribution systems, but gate valves are very powerful and efficient. These valves help in maintaining the pressure of water flow; the regulation of water is operated through an external knob that resembles a handwheel.

Experts suggest that gate valves are ideal for locations with a straight supply line. If used in a complex, more curve system, there is a high risk of the mechanism getting stuck often. Gate valves can be chosen for residential properties and industries with large water distribution systems.

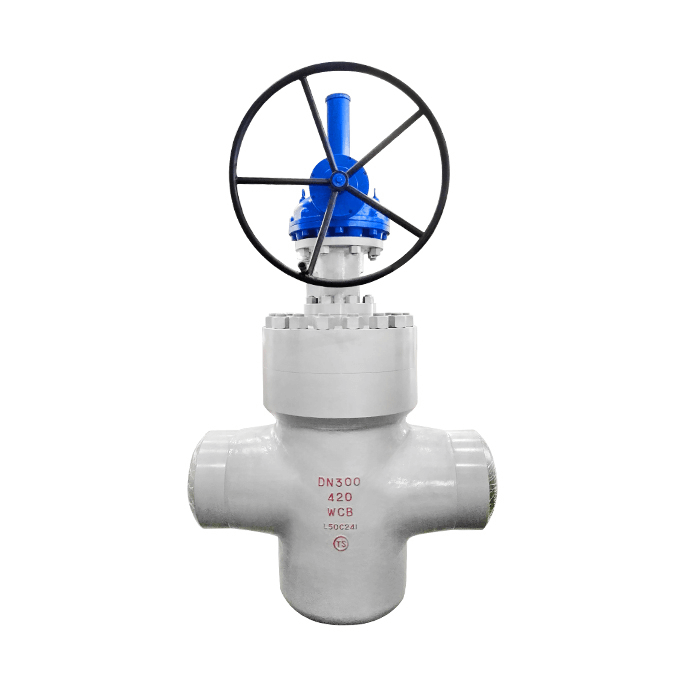

Plug Valve

Cylindrical in shape, the name plug valve derives from a cone-shaped plug fitted inside the valve, which allows the regulation or sudden stopping of water flow. Plug valves are cylindrical in shape and are easy to operate. The best part about these valves is that they can be used with multiple ports to direct water flow into various channels simultaneously.

Plug valves do not go well with gasses, they can only be used for controlling the flow of fluids. Some experts suggest that plug valves can be used as an excellent substitute for ball valves in industrial locations.

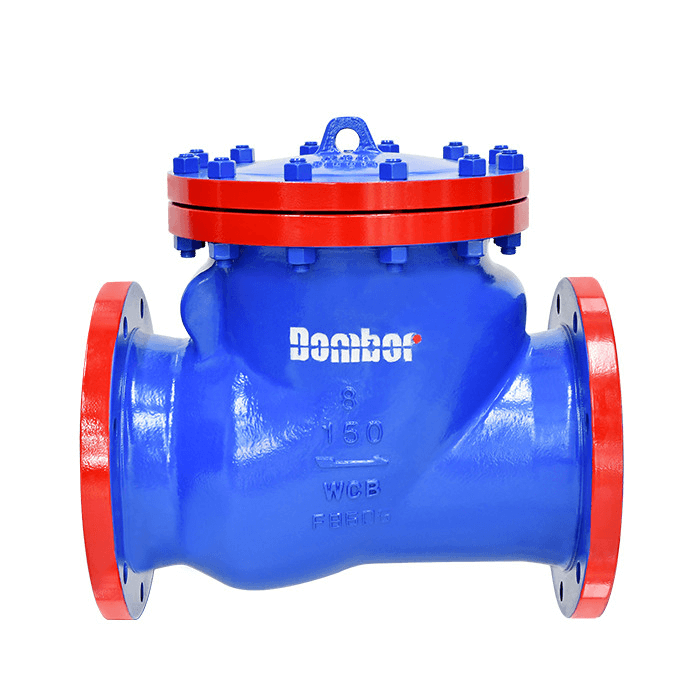

Check Valve

One of the most common types of water distribution valves you come across in industrial settings, check valves are ideal only for supply lines that operate in a single-directional flow. Check valves are the most convenient solution for those supply lines that have a threat of backflows.

Check valves are so convenient in both commercial locations and households because they can prevent drainage or sewage water from entering the clean water supply. No matter where you install them, there is no risk of backflows during irregular water pressure. At homes, check valves are used with sump pumps to circulate water flow in the entire building.

Globe Valve

The name globe valve obviously derives from the spherical shape of the valve’s body. This unique-looking valve is very efficient in industrial settings for distributing water systems. The water flow is controlled through a handwheel or rotating knob. Globe valves can be used for controlling the flow of both gas and liquids. They are most commonly used in residential water supply lines and are very appropriate for industrial uses.

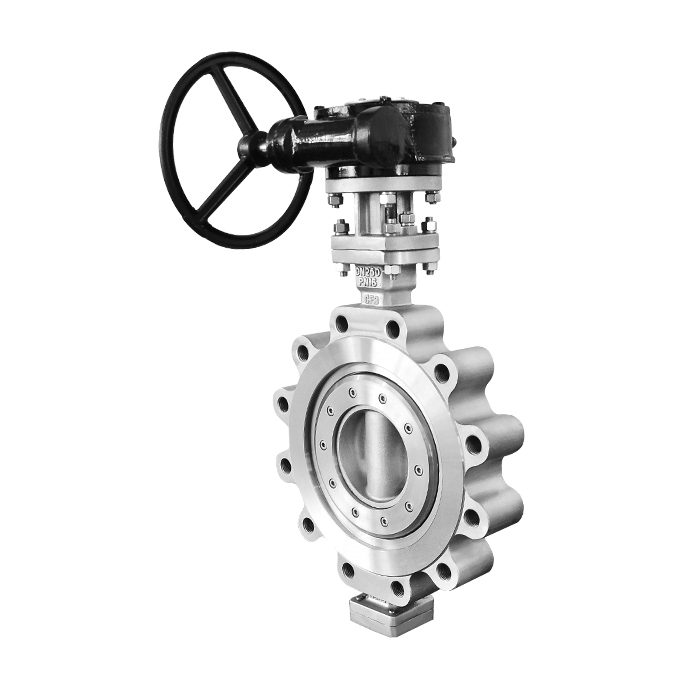

A valve that does not look like a butterfly but looks quite unusual from regular water valves, the butterfly valve is commonly used in industrial settings. The water is regulated through the discs present inside the butterfly valves. This disc rotates for controlling the flow of liquids; however, they are not that useful for gasses.

Experts also suggest that sometimes, butterfly valves can prove to be very inappropriate for high-pressure supply lines, and this is because the rotating discs are very prone to damage in high-pressure supply lines. Abutterfly valve supplier pays more attention to the rotating discs while manufacturing them because controlling water flow largely depends on it. You can also check out a Wafer type butterfly valve.

Needle Valve

The name of the needle valve derives from the spindle fitted inside the valve that gets lifted and lowered to regulate the flow. These valves also include a rotating stem that actuates and helps in controlling water flow most precisely. This is why needle valves differ greatly from the rest of the water valves. These valves come into great use for throttling and regulating water flow. They are ideal for industrial locations where the pressure of the water supply is extremely high.

Materials Used In Making Water Distribution Valves

Usually, water distribution system valves are manufactured with two types of materials; it is either metal or high-quality and tough plastic. While manufacturing water valves, there are a lot of things to be taken care of; every little part attached internally plays a significant role in the mechanism of the valves. During the manufacturing process, particular importance is given to the materials used, and this is because a lot of factors depend on them.

Trusted manufacturers realize how much of risk is involved while dealing with high-pressure water supply, which is why special importance is given to manufacturing materials. Manufacturers often choose sustainable materials in manufacturing their valves.

Mostly, water distribution valves are made of good quality stainless steel, cast iron or cast steel, ductile iron, bronze, brass or other unique materials like aluminum and alloy steel. These materials are commonly used because they have proven most durable, non-corrosive, and equally efficient in maintaining the safety of supply lines.

Durable materials such as stainless steel or cast iron and aluminum ensure there is no rust formation in either the body or the internal parts of the valves, the integral parts like the gates or balls and discs. Other metal alloys, including cast steel or ductile iron, are equally popular, efficient, non-corrosive and non-reactive.

Well, metals and their alloys are not the only kinds of materials used in manufacturing valves; they are also made with high-quality plastic materials that include Polyethylene, carbon fibres, Polypropylene, chlorinated PVC, Acetal Polymers, Polyvinyl Chloride, etc. If you are worried about their durability and resistance as compared to metals, these valves are just as tough and efficient. However, if the supply from pipelines include the flow of fluids and gasses with high temperatures, plastic valves may not be the ideal choice.

Components Of Valves In Water Distribution Systems

A water distribution valve may seem small, but it comprises many little parts which are integral in throttling and controlling the water supply. Here are the components you come across in almost all common types of water valves.

- Handwheels And Handles- Both handles and handwheels are very common in manually-operated valves. They are the most powerful parts of valves because they are in tune with all the other internal components of the valve and can immediately stop or open the flow of water.

- Bonnet- A bonnet is an integral part that supports the opening part of a valve. Bonnets provide strength and support to the body of a valve and also some internal parts that include discs, stems and actuators.

- Body- The outer part of the valve is known as the body. A body holds all the internal components together. The body of a valve is also known as the protective cover which makes the valves strong and durable, and visually pleasing.

- Stem- A vital part of valves, stems support the opening and closing mechanisms. They provide support to rotating discs or gates and balls to regulate and throttle.

- Packing- It is that part of the valve that protects and provides support to the stem. Packing is also very efficient in controlling leaks and damages.

- Seat- It is the surface on which a disc gets rotated. In other words, a seat gives the rotating discs the surface to function.

- Disc- The internal part that controls the flow, the disc gets rotated to circulate water flow.

- Actuator- This part enables the mechanism of a valve to open and close the flow; actuators are adjustable and are found in fully-automated or semi-automated systems.

Applications Of Industrial Valves Used In Water Distribution Systems

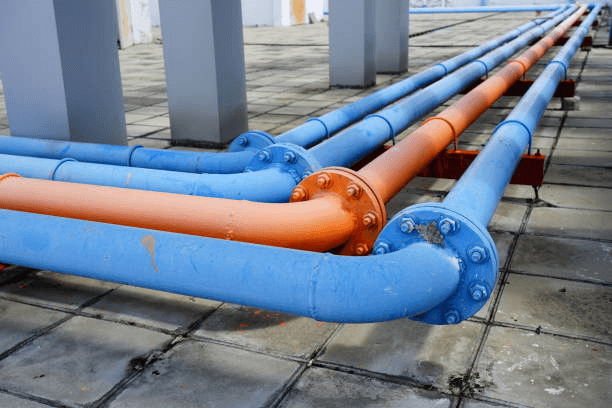

The types of valves used in distribution system vary in industrial settings. Water distribution valves are applicable in four different systems, including:

Dead-End Distribution Systems

Also recognized as a tree distribution system, dead-end systems are the most commonly-used distribution system that includes a single pipeline. This single main supply is then connected with many sub-branches, and the sub-branches are further divided into many small supply lines.

Dead-end distribution systems are most commonly found in residential settings. Their design is simple, easy to operate, and is ideal for circulating flow in a single building. The least number of cut-off valves are required in such a system, and also, the requirement for maintenance is very low.

GridIron Systems

Ideal for both residential and industrial locations, Gridiron systems have their main supply lines operating from the center of a building. These systems have many sub-branches that connect perpendicularly. The special control offered by these systems is their interconnectivity and the lack of any dead ends. The water can arrive from many directions at a time to gush out from a single point.

Radial Systems

A type of water distribution system that is ideal for high-rise buildings and places with high water pressure, radial systems allow any building to have numerous distribution areas. Which is why the distribution is very swift.

Ring Distribution Systems

Also recognized as circular distribution system, in a ring distribution system, the water gets supplied from the mains through a circular area. The pipes are interconnected in such a way that they maintain a circular motion.

Factors To Consider When Selecting Water Distribution Valves

There are quite many factors to consider while investing in water distribution valves. Different types of valves used in water supply and it becomes very challenging to make the right choice. Here are some significant factors that everyone must consider:

Materials Used

Renowned manufacturers are very conscious about the quality and material of a valve. It is the most crucial factor to consider while making a choice. Mostly, in industrial settings, valves are used in systems that handle liquids with extreme temperatures, and for that, taking care of the materials used in manufacturing them is very essential.

If special importance is not given to the material of valves, they can either damage, react with the fluids, or corrode. According to experts, valves made of stainless steel, brass, copper, and aluminum are always the best choice when the supply involves fluid or gas of extreme temperatures. If the supply line is for water, plastic valves are an affordable option.

The Purpose

Determining the purpose for which the valves are to be used is very essential. Such as, the type of fluids or gasses that will be supplied through the distribution system plays a vital role. One has to make sure that the type of valve chosen is appropriate for the type of distribution system.

The Function Of Valves

Every valve shares a different function; some have floating balls to regulate the flow, others have discs or metal gates. Depending on the pressure from the main supply, and if the valve you are choosing is able to control high pressure, you must make a choice. Not every common water valve is ideal for industrial usage, you will have to pay extra attention to this factor.

Size Of Valves

Depending on the size of your supply system, the size of the valve needs to be decided. If the supply and the pressure are huge, a small water valve will be ineffective in regulating the flow. For large systems, you need more powerful and bigger valves.

Industrial valves are built a little differently from residential water valves. Since the distribution systems in industries are huge, the valves are built with care, keeping in mind the huge supply and pressure that would fall on such valves.

Method Of Actuation

Another vital factor to consider is the method of actuation which means, how the valve is operated, is the mechanism simple or complex, and so on. Method of actuation also largely depends on whether the valves are to be operated automatically or manually.

Type Of Maintenance They Require

Maintenance or regular inspection is a headache for all. Usually, every valve type has different requirements for maintenance; some valves do not require much maintenance, while others require a lot. Maintenance is one of those key factors that factory owners need to consider in order to maintain a safe working environment for their workers.

Temperature Conditions

Since supply lines in industries pass fluids with extreme temperature conditions, it is very crucial to make sure the valves are able to withstand such temperatures. For extreme temperatures and pressures, specially-designed valves, such as butterfly valves, and globe valves, can deal well with the systems.

Final Words

Among a lot of varieties to choose from, it becomes very difficult for industries to determine which valves would be the ideal ones for their water distribution systems. But once, the functions of industrial valves are compared, picking the right one becomes easier. Even if the water valves used in residences look exactly similar to those used in industries, their functions are totally different.

While the supply lines at homes are uncomplicated, in industrial settings, they can be very complicated. While in residential locations, valves are attached to water supply lines, in industries, they can be a part of distribution systems, chilled water systems, hot water systems, and wastewater systems. Which is why industrial valves are customized differently. If you wish to buy industrial water distribution valves in bulk or wish to know more about them, then you can contact us here.