Trunnion ball valves are important in many industrial processes, from oil and gas production to chemical manufacturing. These valves are designed to control the flow of fluids, gases, and other materials in a variety of applications. Understanding how industrial ball valves work can help operators select the right valve for their needs and ensure proper operation.

This blog will discuss Trunnion ball valves in detail, including how they work, how they are constructed, and the difference between a trunnion ball valve and a floating ball valve.

What is Trunnion Mounted Ball Valves

Trunnion-mounted ball valves are commonly used in industrial applications that transmit media in pipes at high temperatures and pressure. They are widely used in oil and gas, petrochemical, and other industries to control the transportation of their products through pipelines.

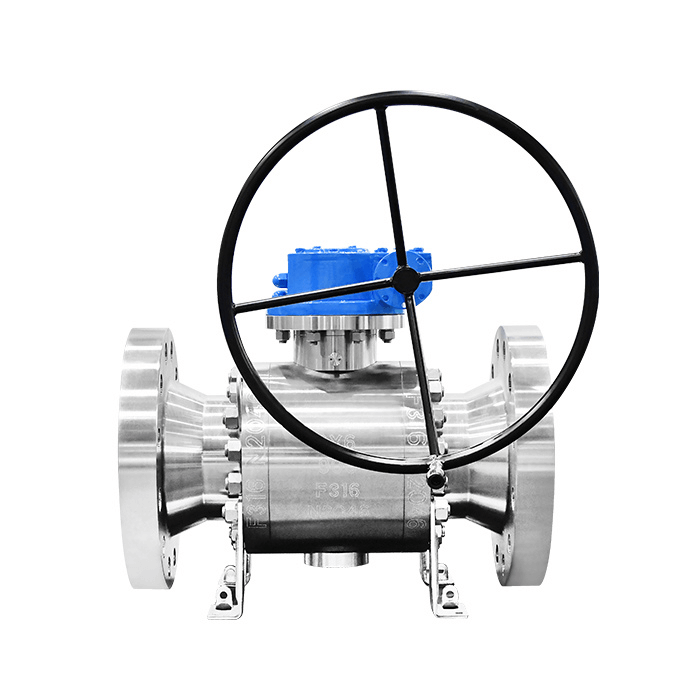

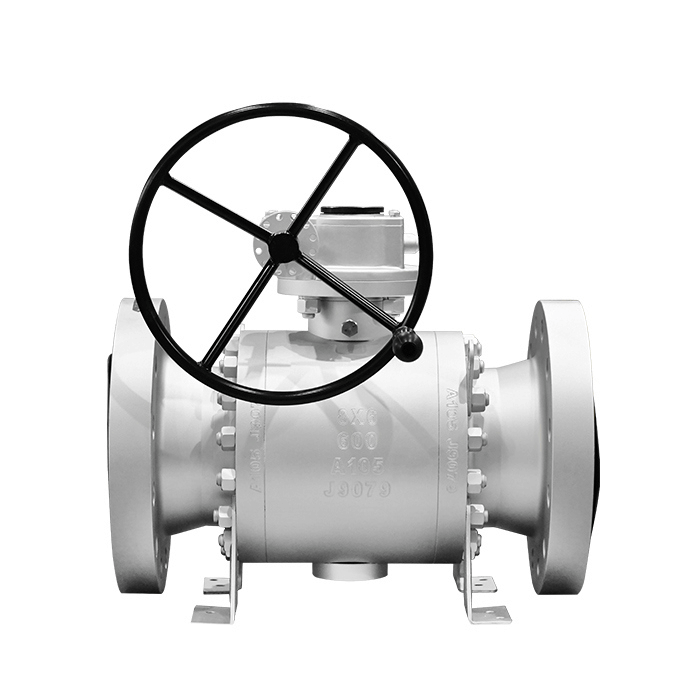

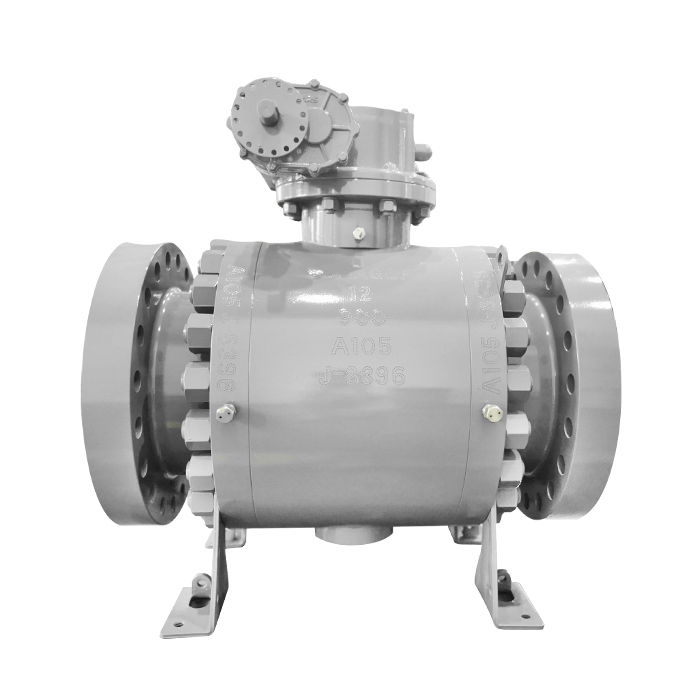

A trunnion-mounted ball valve is an industrial ball valve that controls the flow of fluids, gases, and other materials in a pipeline. The valve is designed with a ball-shaped disc that rotates around a fixed axis, providing tight sealing and control over the flow.

How do Trunnion Ball Valves Work?

Trunnion ball valve manufacturer designs their trunnion ball valve to work in a way similar to a floating ball valve. The working principle of a trunnion ball valve involves rotating the ball to control fluid or gas flow.

When the actuator sends a signal to the stem, it rotates the ball by 90 degrees, opening or closing the valve. The seat ensures that the ball stays in place during rotation. The injection system acts as a partial seal to prevent leakage when it occurs.

To start the oil flow in a trunnion ball valve, the actuator on the valve is rotated 90 degrees, usually clockwise. The actuator is connected to the valve stem, which is linked to the ball.

The rotation of the actuator moves the stem and the ball connected to it. This will result in an unrestricted flow of the substance in the pipe, and reduced pressure in the pipeline. This will restrict flow of the substances in the pipeline.

How is a Trunnion Ball Valve Constructed?

The construction method of a trunnion ball valve used in different industrial valve companies involves the assembly of several components, with specific materials are chosen for their properties and suitability for the valve’s intended application.

- Body: The valve body is the outer shell of the valve that holds all the internal components in place. It can be made of various materials such as stainless steel, carbon steel, or low-temperature carbon steel. The body is typically constructed with flanged, butt-welded, or threaded ends to connect the valve to the pipeline.

- Ball: The ball is a rotating disk that starts or stops the flow of fluid or gas in the valve. It is usually made of materials such as stainless steel, carbon steel, or brass. The ball is designed with a hole in the center to allow fluid or gas to pass through when it is in the open position.

- Seat: The seat is a ring-shaped component that surrounds the ball and ensures that it stays in place when the valve is in operation. It is typically made of soft or Teflon materials or metal materials such as stainless steel. The seat creates a seal between the ball and the valve body to prevent leakage.

- Trunnion: The trunnion is an additional shaft that holds the ball in place and prevents it from moving from below. It is attached to the ball disk with the help of welded joints. The trunnion is usually made of stainless steel or carbon steel.

- Stem: The stem connects the actuator to the ball and ensures that they move together. It is usually made of stainless steel, carbon steel, or brass. The stem is attached to the ball with the help of a ball joint or other connection methods.

- Injection System: The injection system is present in the stem and seat area and acts as a partial seal to prevent leakage when it occurs. It is typically made of soft or Teflon materials and is designed to be replaceable.

Difference Between Trunnion Ball Valve and Floating Ball Valve Working Principle

The key difference between a trunnion ball valve and a floating ball valve is in the way the ball is held in place.

In a floating ball valve, the ball can move in any direction within the valve, and the valve seat is held in place by spring pressure. As a result, the ball is held in place by the pressure of the fluid or gas flowing through the valve.

On the other hand, in a trunnion ball valve, the ball is held in place by two shafts called trunnions, which are attached to the ball. These trunnions are connected to the valve body and act as a pivot point for the ball, allowing it to rotate within the valve while remaining in place. This design allows for a more secure and stable seal, making the trunnion ball valve suitable for higher pressure and larger diameter applications.

The working principle of both valves is based on a quarter-turn motion, where the ball rotates 90 degrees to start or stop fluid or gas flow. The ball is operated by an actuator, which sends a signal to the stem, which in turn rotates the ball to open or close the valve.

Source Trunnion Ball Valves in Dombor

The best place to source trunnion ball valves is with Dombor. Dombor is a leading industrial valve manufacturer located in China. At Dombor, we specialize in producing high quality valves using modern technology and advanced production equipment. We specialize in manufacturing a diverse array of industrial valves capable of handling severe working conditions and perfect for industrial applications.

Your reasons for choosing Dombor as your trunnion ball valve supplier includes:

- Strict quality control – All dombor valves adhere to global standards and are thoroughly inspected during production and tested after production by our excellent quality control team.

- Wide Variety of Products – You can be sure our varieties of products have are available in our store. We also offer customized services to design the trunnion ball valves per the client’s specifications.

- Excellent sales team – from inquiries with our sales team to order processing and delivery, we offer excellent customer service. We are also available for aftersales services.

- Trustworthy Corporate Culture – Founded with the passion to provide excellent products and services, DomBor nurtures and values transparent relationships with clients across the globe.

Conclusion

In conclusion, trunnion mounted ball valves offer several advantages over other types of valves, particularly for applications requiring high flow rates and pressure. Their unique design ensures proper sealing and helps to prevent leakage even under high-pressure conditions.

The trunnion-mounted design also reduces torque requirements and extends the service life of the valve. Getting a trunnion ball valve from a reputable valve manufacturer in china is a step in the right direction. Contact us today to get a quote!