Why Do You Need a Trunnion Mounted Ball Valve

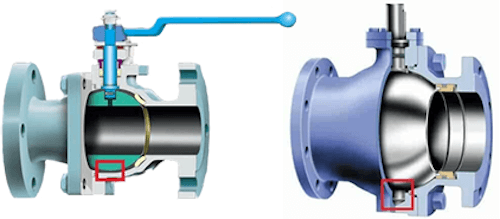

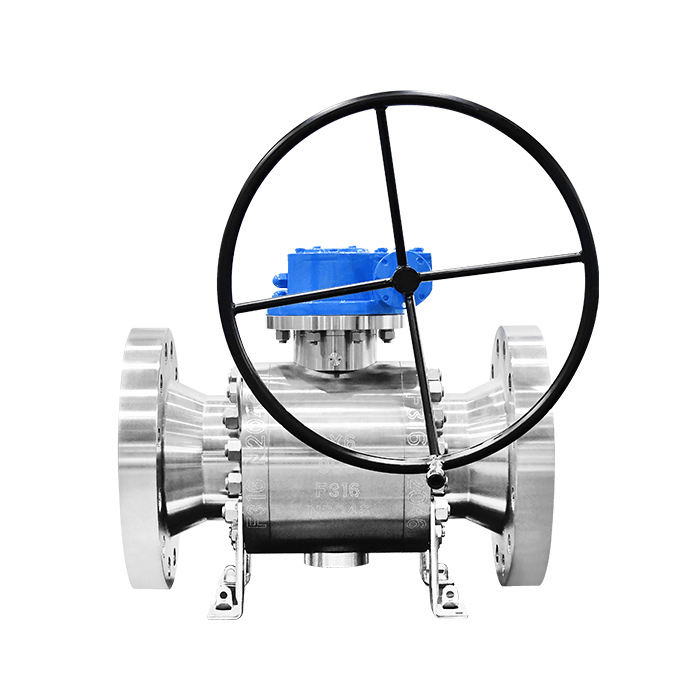

A trunnion ball valve is designed to provide reliable sealing at the upstream and downstream seats in low or high-pressure conditions, allowing for double block and bleed function. This makes wholesale trunnion ball valves suitable for larger-diameter and higher-pressure operations. Also, this valve design requires less torque for operation, hence, they are ideal for automated ball valve applications.