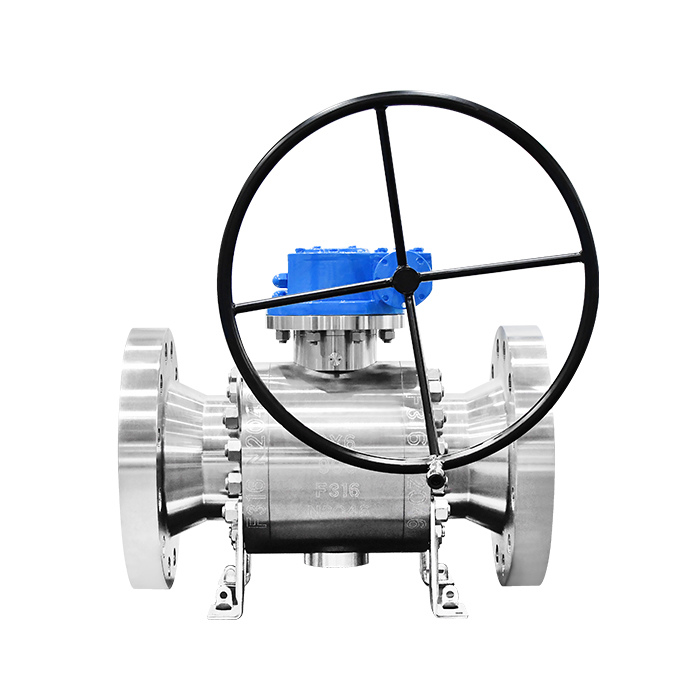

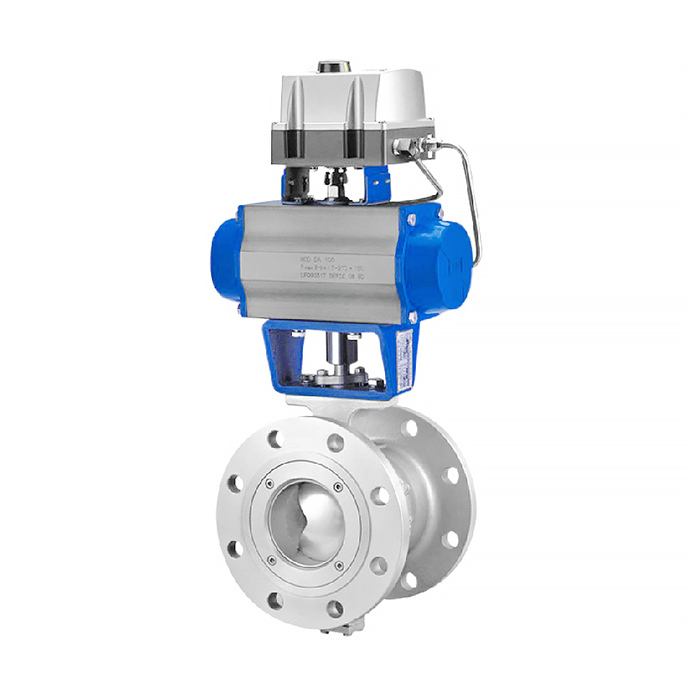

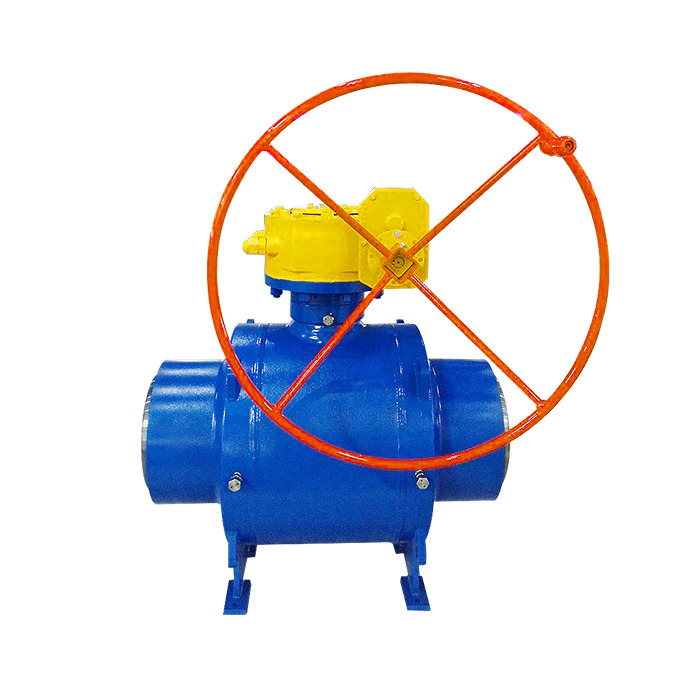

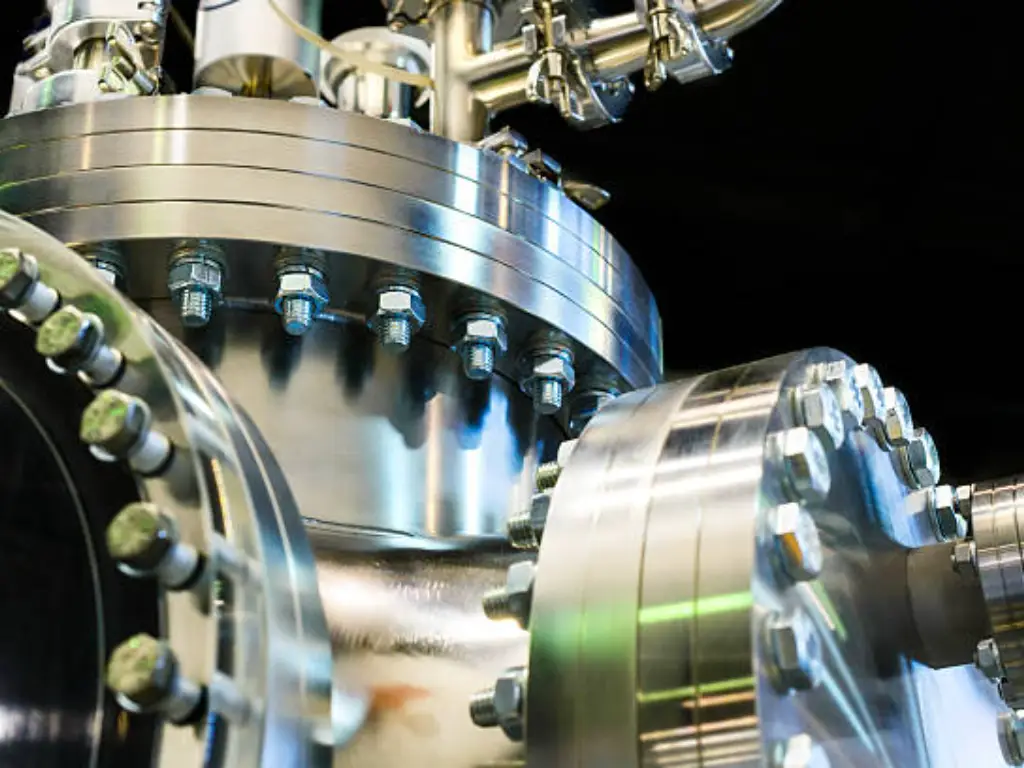

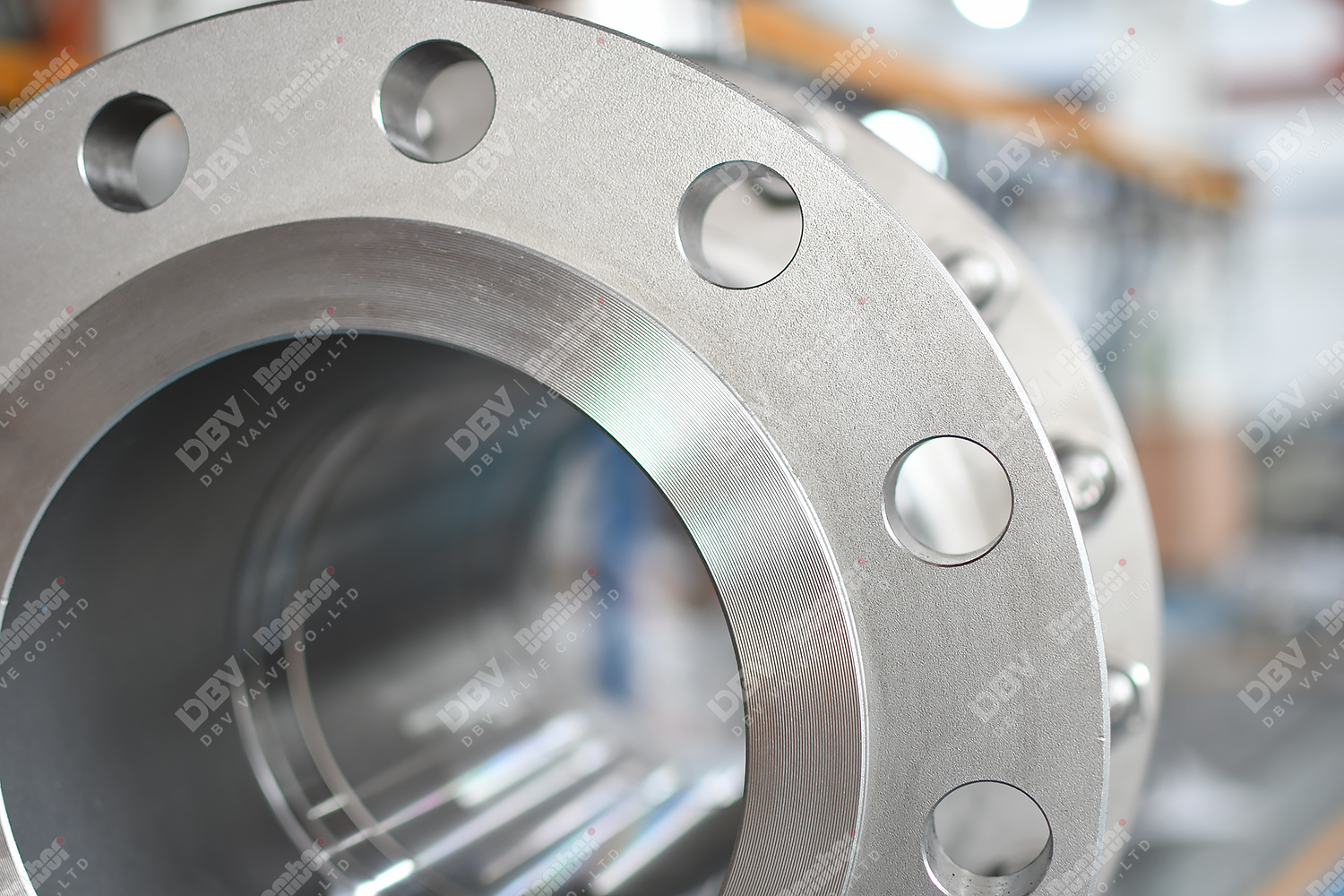

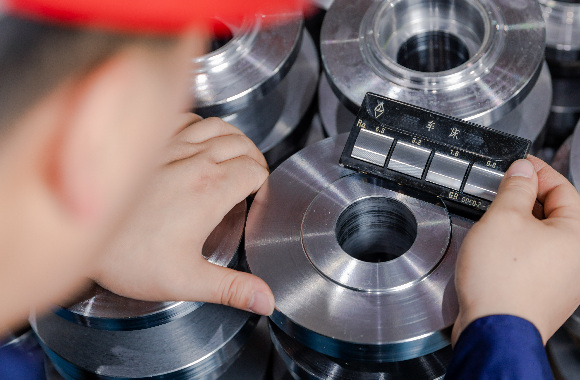

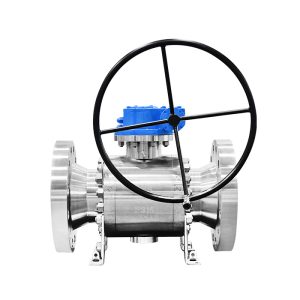

Generating high-quality valve solutions requires a deep insight into market needs. DomBor Valve, as a reliable valve manufacturer, relies on a trusted supply network, the latest production, and assembly machinery, along with digital design capabilities and 20 years of industry experience.