Valves have numerous applications in the plumbing industry. These devices are generally used to regulate the flow of water. When it comes to the plumbing industry, there are multiple types of valves, such as gate, ball, globe, and butterfly valves. Usually, these are used to regulate the volume or pressure of fluids. Since plumbing is basically about fixtures, piping, and controlling fluid pressure, good-quality valves are in significant demand.

When deciding which kind of valve will be the most suitable for an operation, a number of factors need to be considered, making it a challenging task. These valves are typically designed for a particular function and are available in different materials, namely brass, bronze, or PVC, for different types of plumbing systems. In this context, it is essential to get premium-quality valves from a trusted valve manufacturing company.

Further, it is equally important to have a good understanding of the types of valves used in plumbing industry and what are the advantages and disadvantages of each one of them. This comprehensive guide will help you learn about the different types of valves in plumbing systems. This guide will also suggest a few things based on which the correct valve must be chosen. Read below to find out.

What Is a Plumbing Valve?

A plumbing valve is equipment typically used for controlling, regulating, and directing the flow of fluids. This device is essentially helpful in regulating the flow of fluids by opening, closing, or partially closing itself.

Valves are highly significant mechanical devices used for both residential and commercial purposes. These are available in numerous designs and styles, each of them meant for a specific purpose. Ball, gate, butterfly, check, globe, and actuated valves are some of the most common kinds mainly used in the plumbing industry.

Read below to find out how valves play an essential role in the plumbing system.

Why Valve Plays An Important Role In Plumbing Systems?

Valves are an integral part of any plumbing system. They are used to control the pressure and temperature of the fluid as well. They are also helpful in regulating the flow of water and other fluids, and they can be found in various applications, from residential to industrial settings. While valves may seem like simple devices, they play a critical role in the proper functioning of plumbing systems.

There are many different types of valves designed for their own specific purpose. Ball valves, for example, are often used to regulate the flow of water in pipes. Butterfly valves, on the other hand, are typically used to control the pressure of a fluid. Gate valves are another type of valve that is commonly used in plumbing systems; they are designed to open or close a pipe in order to regulate the flow of fluid through it.

While valves serve a variety of purposes, they all share one common goal: to ensure that plumbing systems function correctly. Properly functioning plumbing systems are essential for both residential and commercial settings. In businesses, plumbing systems help maintain sanitation levels and support the needs of customers and employees.

In residential settings, valves are often used to regulate the flow of water to fixtures such as sinks, toilets, and showers. In industrial settings, valves may be used to control the flow of liquids or gases in process piping. Valves can also be used to isolate sections of piping for maintenance or repair.

Valves play an essential role in maintaining proper pressure levels within plumbing systems. Without valves, pipes would not be able to hold back the force of moving fluids, which would cause them to burst. Valves also help prevent backflow, which is when fluids flow backward through pipes due to changes in pressure. Backflow can contaminate clean water supplies and lead to serious health hazards.

No matter what type of valve is being used, they all play an important role in maintaining a well-functioning plumbing system. Without valves, pipes would not be able to properly transport water and other fluids around a building or home. In addition, valves help to keep the pressure and temperature of fluids at appropriate levels, which ensures that the plumbing system as a whole is operating safely and efficiently.

Types Of Valves In Plumbing Based On Their Design

There are several types of valves in piping and plumbing, each with its own unique design. The most common type of valve is the ball valve, which is composed of a ball that sits inside a body with two ports. When the ball is in the open position, water can flow freely through the ports. However, when the ball is in the closed position, the flow of water is blocked.

Another type of valve is the butterfly valve, which consists of a disk that sits on top of a body with two ports. When the disk is in the open position, water can flow freely through the ports. However, when the disk is in the closed position, the flow of water is blocked.

The last type of valve we will discuss is the check valve. This type of valve consists of a flap that blocks one port while allowing water to flow through another port. When water pressure is applied to the flap, it opens and allows water to flow through. However, when water pressure is released, the flap closes and blocks the port.

Industrial Ball Valves

It is significant to know what is a ball valve in plumbing. Industrialball valves are commonly used in plumbing systems to control the flow of water. They are usually made of brass or plastic and consist of a ball that is connected to a handle. The ball has a hole in the center that aligns with the pipe when the handle is in the open position, allowing water to flow through.

When the handle is turned to the closed position, the ball blocks the hole and stops the flow of water. Ball valves, such as 3 way ball valve are easy to operate and can be used to shut off the water entirely or to regulate the flow. You can also look for a reliable trunnion ball valve manufacturer to purchase quality trunnion ball valves that meet the required industry standards and pass the essential certifications.

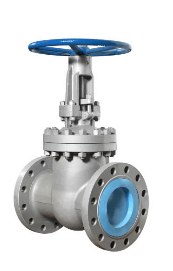

Gate Valves

It is essential to understand what is a gate valve in plumbing. Gate valves are used in plumbing systems to control the flow of liquid or gas. A gate valve plumbing is designed to open and close quickly and can be operated by hand or by automated controls.

Gate valves are available in various materials, including metal, plastic, and rubber. When selecting a gate valve for a piping system, it is essential to consider the desired flow rate, operating pressure, and temperature range.

Globe Valves

A globe valve is a device used to regulate flow in a plumbing system. It consists of a round body with a hole in the center and a disk that covers the hole. The disk can be opened or closed to allow or block the flow of water. Globe valves are often used in applications where precise control over the flow of water is required.

For example, they are often used to regulate the flow of water into a home’s water heater. By opening or closing the valve, the amount of water flowing into the heater can be controlled. This allows for more efficient operation of the system and can help to prevent overloading and damage to the heater.

Globe valves are also sometimes used in irrigation systems. In these applications, they are used to control the amount of water flowing to each plant. By opening or closing the valve, the farmer can ensure that each plant gets the correct amount of water. This can help to improve yields and prevent damage to crops.

When selecting a globe valve for a particular application, it is essential to consider both the size of the hole in the body and the size of the disk. The hole must be large enough to allow for adequate flow but not so large that the valve loses its ability to control flow. Likewise, the disk must be large enough to cover the hole completely when closed but not so large that it is difficult to open or close.

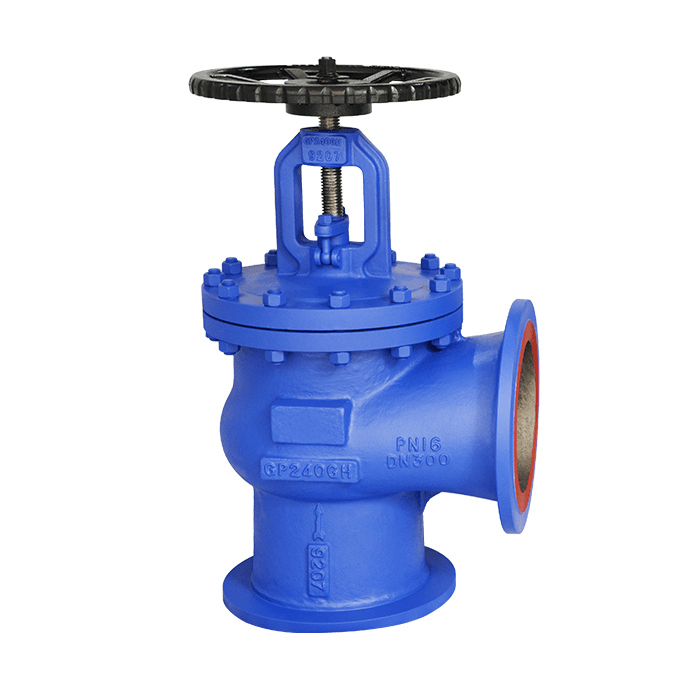

Butterfly Valves

Butterfly valves are often used in plumbing systems, as they effectively control water flow. There are a few different types of plumbing butterfly valve, each of which has its own advantages and disadvantages. The most common type of butterfly valve is the wafer valve, which is well-suited for use with thin-walled piping.

Another type of butterfly valve is the lug valve, which has a thicker body and is, therefore, more durable. Finally, there is the flanged butterfly valve, which is designed for use with thicker-walled piping. You can contact a trusted butterfly valve manufacturer that designs and offers valves from premium-grade materials to cater to the required efficiency levels.

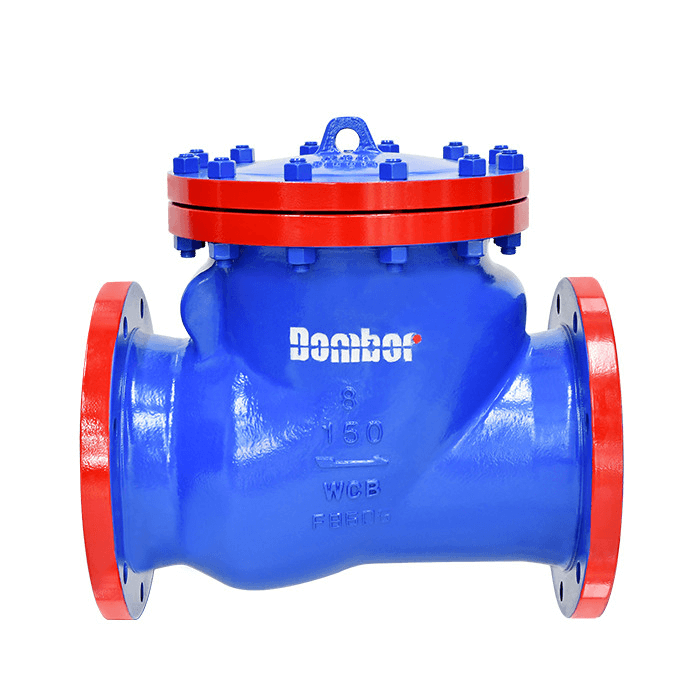

Check Valves

There are many different types of check valve in plumbing systems, each with its own advantages and disadvantages. The most common type of check valve is the ball check valve, which consists of a ball that sits on top of a seat in the valve body. When fluid flow is present, the ball is pushed up off the seat, allowing fluid to pass through.

However, when the fluid flow stops or reverses direction, the ball falls back down onto the seat and closes the valve. Plumbing check valve residential are simple and inexpensive, but they can be susceptible to clogging and may not seal as well as other check valves.

Shut-off Valves

Shut-off valves are an essential part of the plumbing system in any home. Different types of plumbing shut-off valves are used to shut off the water supply to various parts of the house and can be used in case of a leak or a burst pipe. There are two plumbing shut-off valve types: main shut-off valves and individual shut-off valves.

Main shut-off valves for water pipes are located near the water meter or the main water supply line and are used to shut off the entire water supply to the house. Individual shut-off valves are located at each fixture and are used to shut off the water supply to that particular fixture. It is essential to know where the shut-off valves are located in case of an emergency.

Materials Used In Making Plumbing Valve

A plumbing valve is a mechanical device that controls the flow of fluids. There are many different types of valves, each with its own specific purpose. However, all valves have one thing in common: they use a variety of materials in their construction.

The most important thing to consider while making a plumbing valve is the metal from which it is made. The type of metal used will depend on the specific application for the valve. For example, brass is commonly used for valves that control water flow, as it is resistant to corrosion. Stainless steel is another popular choice for valves, as it has a high resistance to temperature and pressure changes. These are also available in materials such as PVC and bronze.

In addition to the metal used for the body of the valve, other materials are also crucial for its proper functioning. The seats and seals within the valve must be made from materials that are compatible with the fluid being controlled. For example, rubber or plastics are often used for these purposes. Finally, lubricants may be required to keep the moving parts of the valve functioning smoothly. We also offer quality assurance to ensure the required standards are maintained.

Components Of Plumbing Valves

Read below to find out the essential components of plumbing valves.

Main Body:

Cast iron, ductile iron, or steel are generally used for an underground valve’s main body. The primary body of the valve must be made of a corrosion-resistant material in order for it to last for a long time. To further lower the risk of corrosion, the body of the valve is frequently coated with an epoxy resin layer or another kind of protective coating.

Bonnet:

An underground valve’s bonnet plays a critical role in the valve’s overall performance. The bonnet aids in sealing the valve and preventing impurities from entering the interior. The bonnet also assists in shielding the valve’s internal parts from damage.

Ports:

The ports of an underground valve control how gases and liquids enter and exit the device. Depending on the size and kind of valve, there usually are two or three ports. Fluids or gases enter the valve through the inlet port, and they exit through the outlet port. The vent port is the third port that is utilized to release the internal pressure of the valve.

Actuator:

A valve that is installed below ground level is called an underground valve. The valve’s actuator is the part that manages the valve’s opening and shutting. There are many various kinds of actuators, but the hydraulic actuator is the one that is most frequently employed in underground valves. Hydraulic actuators are typically used for generating huge pressure.

Disc:

A disc is a necessary part of many valves, mainly underground valves. Discs are built to withstand the extreme pressures and temperatures experienced in underground environments. This is so because they are made of strong, long-lasting materials.

Seat

A seat is a part that aids in regulating the water flow via the valve. Generally, it is constructed of materials like metal or plastic that can sustain the pressure of the water. The seat is typically found near the base of the valve, where a handle or lever can be used to open and close it.

Where Can The Plumbing Valve Be Used?

Plumbing plays a vital role in many aspects of life, and plumbing valves are essential components that help regulate the flow of liquids and gases. Read below to find out about the various places where plumbing valves can be used, as well as the different types available.

Conveying Heating And Cooling

There are a few key places in the home where the plumbing valve can be used to help regulate heating and cooling. One of these is in the power generation industry. Valves play an integral role in this sector due to their extreme durability and reliability in withstanding extremes of temperature and pressure conditions.

Gas And Oil

Valves play a significant role in the refining and petrochemical industries. When it comes to complex operating conditions, it is essential to choose premium-quality valves that can offer a great lifespan and are easy to maintain. Our valves pass industry standards and are designed to prevent any potential damage to the piping systems and can easily control the flow of gases and fluids, such as acids and oil.

Wastewater

The valves are a significant part of the plumbing system. It controls the water flow in the pipes. There are different types of valves used in plumbing for different purposes. The most common type of valve is the stopcock. It is used to control the water flow from the main supply pipe to the taps in your home.

The stopcocks or plumbing stop valves types are usually located in the basement or utility room. If there is a problem with the water supply, the stopcock used in stop valves plumbing can be turned off to prevent water from flowing inside. Another type of valve is the check valve. It allows water to flow in one direction only. Check valves are often used in conjunction with pumps. They are also used in some irrigation systems.

The third type of valve is the pressure relief valve. These types of valves used in piping systems are installed to release pressure if it gets too high. Pressure relief valves are important in preventing explosions and other damage that can occur when pressure builds up in a closed system.

Water Distribution

There are many places where plumbing water valves can be used in the pipeline transport industry. These valves are used to prevent any water clogging and to ensure the smooth transportation of fluids and gases. At DomBor, we offer high-performance valves that meet global certifications like ISO 14313 and that can be customized depending on the specific requirements.

API And ASME Standards For Plumbing Industry

There are many different standards that apply to the plumbing industry. Two of the most important ones are the API (American Petroleum Institute) and ASME (American Society of Mechanical Engineers) standards.

The API standard covers the design, manufacture, and installation of piping systems in oil and gas refineries. It includes requirements for materials, welding, pressure testing, and safety.

The ASME standard covers the design and construction of pressure vessels, such as boilers and storage tanks. It includes requirements for materials, welding, inspection, and safety.

Both of these standards are very important in ensuring that plumbing systems are safe and fit for purpose. Our valves pass global certifications, such as ISO, to ensure the guaranteed quality of the products. Besides, we also guarantee sustainable development to ensure zero carbon emissions and reduced environmental impacts.

Factors To Consider When Selecting Valves In Plumbing System

There are various factors to consider when selecting valves for use in a plumbing system. Some of the key considerations include the type of fluid being transported, the operating conditions and pressures, the required flow rate, and the desired level of control. Depending on the application, other features such as corrosion resistance and size may also be important considerations.

Type Of Fluid:

The type of fluid being transported is an important consideration, as some valves are only suitable for use with certain types of fluids. For example, butterfly valves are typically only used with low-viscosity fluids, while ball valves are more versatile and can be used with a variety of different fluids.

Operating Conditions:

Additionally, the operating conditions and pressures must be taken into account when selecting a valve, as some valves are only designed for use in specific conditions. For example, high-pressure valves must be able to withstand high levels of pressure without leaking or failing.

Flow Rate:

The required flow rate is another crucial consideration when selecting a valve. This is because the size of the valve must be matched to the desired flow rate in order to achieve optimal performance.

Rate Of Control:

Additionally, the level of control that is required will also impact the selection of the valve. For applications where precise control is necessary, such as in steroid or insulin pumps, proportional valves may be used. However, for applications where less precise control is sufficient, such as in general water systems, simple on/off valves may be used instead.

Contact Professional Plumbing Valve Manufacturer – Dombor Valve

Valves are an essential part of any plumbing system and should be chosen with care. Understanding which type of industrial valve to use for a given application is paramount to ensure the proper functioning of the plumbing system. With this knowledge, one can make sure that the pipes are appropriately plumbed and free from leaks or other problems caused by faulty valves.

If you are looking for a reliable plumbing industrial valve company, you can contact us to get access to an extensive range of premium-quality industrial valves that will best suit your requirements.