Introduction to Valve Connection Types

As I stand amidst a world woven with intricate networks of piping systems, the heartbeat of industrial symphony, it dawns upon me—the sheer brilliance of engineering is often hidden in the smallest details, like the connections of a valve. It’s these connections that hold the realms of high pressures and the subtleties of flow control in a firm embrace, ensuring that each drop of fluid narrates the saga of precision. Valve connections, they’re not just points where pipes and valves conjoin; they’re the sinews that join the muscle of a valve to the skeleton of the piping system. With an array of types, from the steadfast ball valve to the vigilant solenoid valves, each plays its part in this grand industrial orchestra. Ah, the dance of NPT threads and the romance of a tight seal—it’s poetry in motion, ensuring every pipe size and valve body resonates with efficiency. Whether it be union connections singing in harmony with pipe tape or a compression nut waltzing with a socket weld, there’s a rhythm to every connection type. And it’s not just about strength; it’s about finesse—the right end connection crafting the perfect flow, as if it were the breath of industry itself. So, let’s embark on this journey together, unraveling the threads of knowledge as we delve into the world of valve connection types. It’s not just a tale of steel valves and brass valves, but a narrative woven with the threads of strict standards and the hues of industrial applications.

The Benefits of Proper Valve Connection Selection

Improving System Integrity Through Correct Connections

Imagine a world where each connection is a promise—a promise of integrity and reliability. The correct valve connection fortifies the very essence of a system, much like a steadfast handshake between components. It’s not merely a fusion of metals; it’s a convergence of trust. When one opts for the correct valve connection type, they’re not just assembling a system; they’re architecting a fortress capable of withstanding the sieges of high pressure and the ambushes of corrosion. It’s like choosing the perfect end face of a valve—a decision that can mean the difference between a system’s triumph and its downfall.

Cost-Effectiveness and Valve Connection Types

In this intricate dance of economics, every penny counts, doesn’t it? Choosing the apt valve connection type is akin to investing in a treasure chest of savings. The right connection minimizes the need for frequent maintenance and upholds the system’s youth, much like a solid metal plate shielding the parts of the world against the tests of time.

The symphony of cost-saving extends beyond the initial notes of purchase to the ongoing melody of operation. It’s not just about the valve port or the type of thread; it’s about the harmony of longevity and efficiency that sings sweetly to the tune of fiscal prudence.

Common Valve Connection Types

Threaded Valve Connections

Threaded connections, the artisans of the valve world, meticulously craft the bonds between pipes and valves with the finesse of a pneumatic actuator at play. In this realm, NPT threads whisper tales of tradition, as they weave the fabric of American national standards with every spiral. To grasp the essence of a threaded connection is to understand the elegance of a small valve making its mark in the vast expanse of a piping system. It’s a narrative that speaks volumes of industry standards, where each turn is a verse in the ballad of functionality. Now, the story of threaded connections isn’t without its ebbs and flows. The advantage, one could say, is akin to the ease of a soft hose connecting with a release ring—simplicity and speed are the heroes here. Yet, there’s a flip side, much like a single hinge bearing too much strain, the risk of leaks whispers caution in the winds.

Welded Valve Connections

Welded connections, the stalwart guardians of the valve world, bond with an unwavering grip, as permanent as the mountains themselves. The process, as riveting as any industrial application, forges a bond that defies the ravages of time and pressure, akin to a solenoid valve standing sentinel against the torrents.

In the vast landscape of options, choosing a welded connection is much like selecting a steel valve for its unyielding strength. It’s ideal for scenarios where the pipe sizes demand a warrior’s resolve, where the battle isn’t just against the elements, but against the very pressures that seek to undermine the integrity of the system. When the wall thickness calls for a fortress-like bond, welded connections rise to the occasion, offering a bulwark against the potential onslaught of leaks and failures.

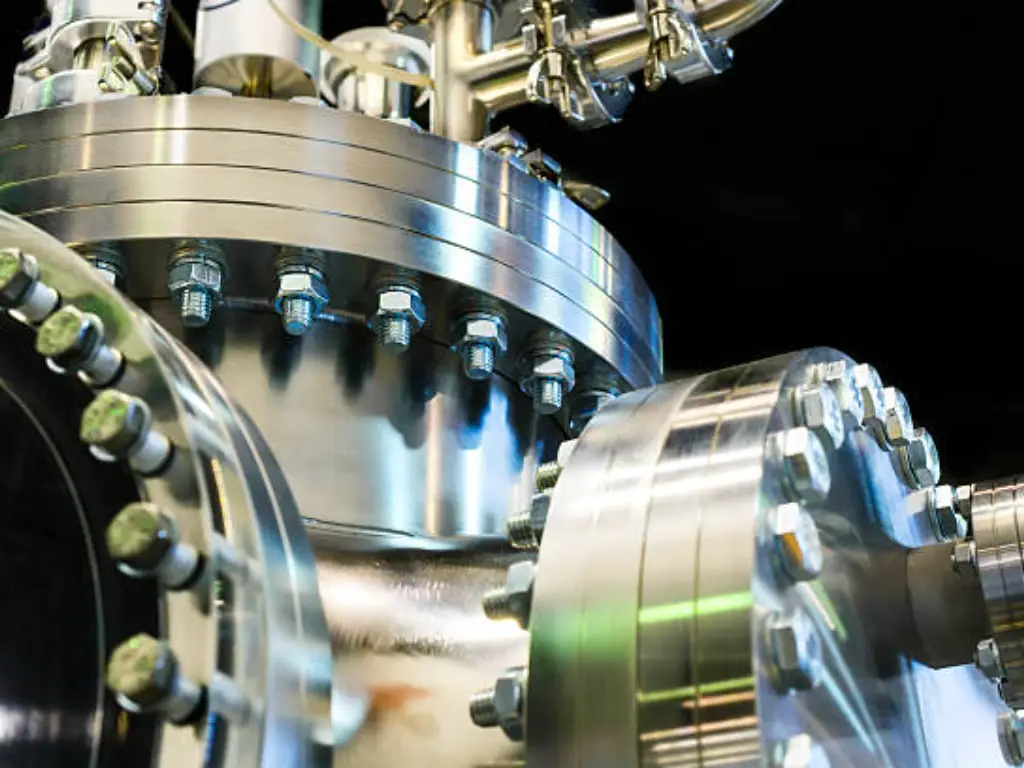

Flanged Valve Connections

Flanged connections, the diplomats of the valve world, offer a blend of strength and sophistication. They stand out like solid metal plates ready for a grand assembly, bolted together with the precision of an automotive engineer. These connections are the cornerstone of industrial applications, where the need for robust yet detachable joints takes precedence. The majesty of flanged connections comes with its own set of scales. On one side, the ease of assembly and disassembly shines bright, much like a hinged clamp that offers both security and flexibility. Yet, on the other, the requirement for more space and the potential for bolt-hole misalignment casts a shadow, reminding us that even the mightiest connections must be approached with a blend of respect and caution.

Compression Valve Connections

Compression connections, the agile acrobats of the valve world, perform with a grace that belies their strength. A compression nut tightens, bringing together the pipe and the valve body in an embrace as intimate as a whisper, creating a seal that is both tight and forgiving, much like the gentle grip of a hose clamp. These connections find their stage in the quieter corners of the world, like residential plumbing systems, where the drama of high pressure takes a back seat to the subtleties of domestic flow. They are the unsung heroes in the walls of our homes, working tirelessly, unseen, ensuring that every drop of water reaches its destination with the promise of purity.

Union Valve Connections

Union connections, the negotiators of the valve world, understand the art of compromise. They bring together disparate parts of a system with a union connection that allows for disassembly without the drama of a full system shutdown. It’s a connection that knows the value of peace, offering a truce between the need for security and the necessity for maintenance. When pitted against their kin, union connections offer a middle ground, like a single hinge door that can swing both ways. They may not boast the permanence of welded connections or the sheer holding power of flanged ones, but they offer a versatility that is invaluable in the ever-changing landscapes of industrial applications and residential plumbing.

Manifold-Mount Valve Connections

Manifold-mount connections, the strategic planners of the valve world, offer a centralized point of control, much like a general overseeing a battlefield from a vantage point. They allow for a single valve body to become the nexus of multiple pathways, directing flows with the precision of an asme standard. The manifold-mount stands tall, offering benefits that resonate with the efficiency of a well-oiled machine. They reduce the need for multiple connections, minimizing potential leak points and creating a system that is as sleek as it is functional, echoing the industry standards set by the American National Standards Institute.

| Connection Type | Applications | Required Accessories | Pros and Cons |

| Threaded | General plumbing, small systems | Teflon tape, wrench | Easy to install with common tools, but can be prone to leaks if not sealed properly. |

| Welded | High-pressure systems, industrial | Welding machine, safety gear | Extremely durable and leak-proof, but permanent and difficult to modify. |

| Flanged | Large industrial systems | Gaskets, bolts, nuts | Strong and can be dismantled, but requires space and precise alignment. |

| Compression | Residential plumbing, small pipes | Compression nut, ferrule | Simple to fit without soldering, not suitable for high-pressure applications. |

| Union | Systems requiring maintenance | Union fitting | Facilitates easy disconnection for maintenance, but is bulkier than other fittings. |

| Manifold-Mount | Complex systems, multiple lines | Manifold block, seals | Centralizes connections to reduce leaks, complex initial setup. |

Valve Connection Standards

National Pipe Thread (NPT) Standards

NPT standards, the script that American national standards follow, dictate the narrative of threaded connections with an authority that is both revered and adhered to. This standard is the language spoken by every npt connection type, ensuring that each thread is a word, each turn a sentence in the story of secure connections.

British Standard Pipe Threads (BSP)

Across the pond, the BSP standard narrates its own tale. It’s a dialect that has been adopted in many parts of the world, a European standard that stands shoulder to shoulder with its American counterpart, ensuring that the dialogue of connections is both diverse and inclusive.

Metric Thread Standard (M)

Then there’s the Metric thread standard, the M, which like a universal translator, bridges the gap between differing systems. It’s the industry standard that allows for a seamless conversation between valve port and pipe, ensuring that no matter the origin, the flow of communication remains uninterrupted.

Valve Connection Types for Specific Applications

High-Pressure Systems and Valve Connections

In the world of high pressure, the choice of a valve connection type is akin to selecting the right armor for battle. It’s a decision that can safeguard the very lifeblood of an industry, ensuring that every valve pipe and connection valve stands resilient against the onslaught of force.

Valve Connections in Residential Plumbing

In the quieter realm of residential plumbing, the connecting valve and connecting pipe speak in hushed tones, ensuring that the sanctity of our homes is preserved with connections that whisper reliability and whisper even softer when it comes to maintenance.

Installation and Maintenance of Valve Connections

Best Practices for Installing Valve Connections

The art of installing valve connections is a craft that demands both attention and finesse. It’s a process that requires the right pipe connections and the wisdom to apply pipe tape where necessary, ensuring that each valve pipe fitting is not just a connection, but a covenant of reliability.

Identifying and Solving Leak Problems

Leaks, the bane of any system, are often the telltale signs of a connection in distress. Identifying them requires a keen eye and solving them, a steady hand—a hand that knows when to tighten a hose clamp and when to replace a pipe thread connection.

Maintenance Tips for Different Connection Types

And then there’s maintenance, the hymn of longevity. Each valve connection type sings its own tune, and knowing the lyrics can mean the difference between a system that thrives and one that merely survives. Whether it’s the regular check of bolt holes in a flanged connection or the gentle tightening of a compression nut, maintenance is the melody that ensures the music never stops.

Wrapping it Up

In the end, valve connections are super important. They’re like the unsung heroes of our pipes and systems. When we pick the right one, it’s like making sure our systems are strong and won’t let us down. It’s not just about sticking pieces together; it’s about making sure everything works smooth and lasts long. So, we gotta give a big thumbs up to those little connectors. They might be small, but they make a huge difference in keeping everything running right.