The throttling process takes place inside an industry’s piping system to reduce pressure and speed. It regulates the flow from one point to the other, i.e., from a high volume of pressure to a lower one, and prevents the system’s performance degradation. Since throttling is a vital part of the industry, throttling valves all serve these functions. This industrial ball valve is designed especially for throttling, including gate, ball, butterfly, needle, diaphragm, and other valves.

If you’re confused about whether this valve is helpful for your system, you’re at the right place. This blog will discuss the importance, working, types, and applications of various valves for throttling to help you make the right decision. So, let us begin!

What are Throttling Valves?

Throttling valves are a vital component of an industry’s architecture as it regulates the flow in the system. Its primary function is to start, stop, and monitor the fluid flow throughout a pump. Since there is a high-pressure difference between the upstream and downstream sides of the valve that increases with the rise in flow restriction, throttling devices are vital. Users employ several control methods for controlling these valves.

A flanged butterfly valve can function as throttling valve under varied conditions. It works by restricting the cross-sectional area through which a fluid flows, causing a decrease in pressure and flow on the unrestricted or downstream branch of the system.

These devices not only help start and stop the process of a liquid but also offer flow with assured pressure by leaving the valve moderately or fully open. It also helps control the direction of fluids or gases with tension and lets the operators reduce the volume and pressure of the media flowing through the system.

How Do Throttling Valves Work?

Throttling valves are regulating devices since their discs can monitor the temperature, flow, and pressure of the medium passing through them. The more restricted a valve is, the more pressure will pass through it. If you also work in the industry and often wonder how throttling valves work in many applications, let us throw some light on the topic.

To begin with, inside a pneumatic throttle valve, an obstruction creates so that the parameters like flow velocity, temperature, pressure, etc., are achieved as needed. The design restriction and friction affect the flow generated while flowing. The throttling valve stem frequently raises and lowers to adjust the size of the path throughout the device. The valve stem can also close completely to stop the flow from passing through.

When the flow path opens by turning the handwheel manually, the valve stem rotates, and the gate lifts, offering a straight movement of the gate. This valve functioning is especially vital in gas processing plants, chemical plants, and other industries where pressure is low but the temperature is high.

If you’re wondering whether all industrial valves can throttle, then it’s not the case. All industrial valves cannot function as a throttling devices because they have different designs. If it cannot throttle, it cannot serve its purpose. Its design must be up to a standard to function rightly.

Types of Throttling Valves Based on Their Design:

Throttling valves start, stop, and regulate the fluid flow from one point to another in an industry. When there is a high-pressure difference between the upstream and downstream sides of the device, a hydraulic throttle valve can adjust it. The pressure drop increases with the increase in flow restrictions. Several methods are employed to control these types of throttling valves.

Different valves can work as throttling valves in varied working conditions. Here we have listed some of its most common types based on their design:

- Globe Valves

It is one of the most common valve designs used in industrial applications. The build of a globe valve includes a disc to offer the required restriction to function as a throttling control valve. Such a design allows proper control to let only the required amount of media pass through. It regulates flow and pressure and can completely stop the flow. When the valve fully opens, it provides a much higher pressure loss since its design forces the fluid flow to change direction within the valve.

The most significant advantage of a globe valve is its seat sitting, which is parallel to the flow, ensuring minimal erosion. But it is vital to note that all globe valves need power or an automatic actuator for high-pressure applications.

- Butterfly Valves

A butterfly valve is probably the most suitable design for throttling applications. It is so because it can easily create throttling by opening a little to let the media pass through the body. Despite being available in various sizes, valves bought from a trustable butterfly valve manufacturer can conveniently work in limited spaces or congested workspaces.

The best thing about butterfly valves is they are highly watertight even after prolonged use. A controller can efficiently operate it using a gearing mechanism, hand wheel, or a wrench. Butterfly valve throttling is achieved when the disc is in a partially open position. But, since it is always in the path of the media, the valve is susceptible to erosion. A throttle butterfly valve is ideal to use in water distribution systems.

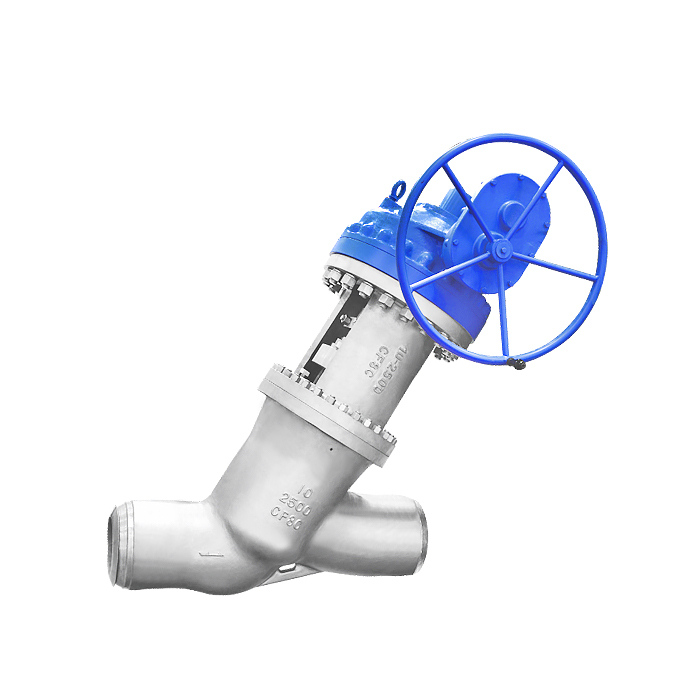

- Industrial Ball Valves

An industrial ball valve features a metal ball with a hole in its center between two placeholders. It functions best when used for throttling gases in low-flow applications. Its design allows it to close and hold fluids, gas, and vapor while providing a minimal drop in pressure, all thanks to its non-sticking design when fully open.

When using a 3 way ball valve for throttling applications, it is critical to note that it is available in two types – the full-bore and the RBbore. While a full-bore valve has an equal internal flow of the entire area, an RBbore’s flow area is less than the inner diameter of the pipe. One can use a full bore valve for quick, complete release of flow. Ball valve throttling is a great option if budget is a central concern.

- Pinch Valves

As their name suggests, pinch valves are lightweight and easy-to-maintain devices widely used in throttling applications, especially for sterility and sanitary purposes. The design of these linear motion valves includes a soft liner and smooth walls, allowing them to throttle and shut off efficiently. A pinch valve can easily handle various solid materials, slurries, and dense fluids as it features a pinch tube to regulate the flow.

- Diaphragm Valves

If the application involves moderate temperature and pressure, diaphragm valves are an appropriate choice to use as throttling devices. Such a design can easily monitor and control the flowing media to offer the required restriction.

- Needle Valves

Industries requiring high-precision applications can use needle valves for throttling proposes. It is so because their design includes a needle-like disc that moves continuously to regulate the fluid flow. But remember that thicker and viscous media are unsuitable for a pneumatic needle valve.

- Expansion Valves

The last valve design widely employed in throttling applications is the expansion valve. These devices are available in numerous designs, including manual expansion, thermal expansion, capillary expansion, and floating ball-type extension. Expansion valves function best when used in refrigeration systems for throttling.

Materials Used In Making Throttling Valves:

- Carbon Steel

It is the most common material used to build throttling in valves due to its superior mechanical properties. Carbon steel offers good resistance to stress corrosion and sulfides. It has a favorable temperature and fatigue strength and is also highly sturdy. One can easily forge or cast it according to the requirements.

- Stainless Steel

If the throttling valve is required for petrochemical or seawater services, the one made of duplex stainless steel is the best. It is so because stainless steel offers high strength and resistance to pitting and crevice corrosion. A stainless steel ball float valve is resistant to high-temperature oxidation and has better physical and mechanical characteristics than carbon steel. It offers high corrosion resistance to different environments and is not susceptible to corrosion cracking.

- Cast Iron

This material offers a significant cost advantage to the users. It has a variety of service applications and is ideal for making throttling valves for water, steam, oil, and gas services. Such valves are suitable for handling chemicals, dyestuff, paints, textiles, and many other industrial goods with little or no consequence of pollution.

- Aluminum

Another common material used in valve construction is aluminum. It is a non-ferrous, lightweight metal exhibiting excellent atmospheric corrosion resistance. It is suitable for constructing the exterior components of a throttling valve, such as the hand wheels and identification tags.

Components of Valves for Throttling:

- Casing

A case is an outer body of a throttling valve, also known as its shell, holding all the valve parts together. The shell of a cast iron ball valve is the first pressure boundary that resists fluid pressure loads from connecting piping. Its ends connect the device to the piping or equipment nozzle through different end connections, such as butt or socket welded, threaded or flanged.

- Port

It is the opening point of the valve body, allowing the flowing substances to enter to leave. A port can be multi-ported or dual-ported, depending on the application. A valve must always open or close using the handwheel method since taking the help of tools might damage the device.

- Stem

Its purpose is to transfer the motion from the handle to the controlling disc. If this part of a valve is damaged, it can cause severe leakages. It usually connects to the handwheel, actuator, or lever at one end and on the other side to the disc.

- Bonnet

It refers to the cover for the opening in the valve shell. It is cast or forged of the same item that is used for constructing the body. It usually connects to the body through a threaded, bolted, or welded joint. During an electric actuator valve construction, the attachment of the bonnet to the body is considered a pressure boundary. It means that the weld joint or bolts connecting the bonnet to the body are pressure-retaining parts.

- Actuator

The function of an actuator is to control the valve activity by fully opening or closing the device. It produces linear and rotary motion of an origin of power under the action of a source of control.

- Disc and Seat

A disc is the chief element of a valve body used to control the flow of liquids and gases. Another critical component of a valve is the seat. The purpose of a valve seat is to offer a tight sealing to the disc for better monitoring. A valve may equip one or more than one seats.

- Trim

These are the removable and replaceable parts of a valve that frequently comes in contact with the flow medium. It includes a valve seat, disc, gasket, spacers, guides, bushings, and internal springs. All the motions and flow control of a wholesale actuated gate valve are possible because of the trim.

- Gasket

It is a critical component of the valve body as it helps prevent any gas or liquid leakage in the device, thus allowing the valve to function at its best.

Applications of Industrial Throttling Valves:

Throttling valves are available in various designs for employment in a broad range of industries listed that are in the next section.

- Air Conditioning systems

An orbit rising stem ball valve is used in air conditioning systems to reduce the high pressure of the liquid refrigerant. It ensures the pressure difference between the condenser and evaporator remains optimal and makes the liquid refrigerant in the evaporator evaporate and absorb the heat under low pressure. It thus allows the entire air conditioning system to achieve the purpose of cooling.

Such a device can also adjust the flow of refrigerant into the evaporator. It allows the device to adapt to the change in the heat load of the evaporator, thus allowing the refrigeration device to work more efficiently and quickly.

- Steam Applications

The purpose of a throttling valve in steam applications is to reduce the pressure in a steam line. It is suitable for reducing the steam flow rate and preventing flashing. Without a throttling valve false reading may be sent to the boiler blowdown controller, resulting in the blowdown valve powering on or off repeatedly.

- Chemical Industry

A v port ball valve is widely used in the chemical industry to control the flow rate and the number of chemicals such as scales, wax, and corrosion inhibitors at the sub-sea zone.

- Refrigeration

This device reduces the refrigerant condensing pressure (high pressure) to the evaporating pressure (low pressure) by a throttling operation and supervises the liquid-refrigerant flow to the evaporator to match the equipment and load characteristics.

- Food Processing

In the food and beverage industry, throttling valves connect and control the conveyance pipes. They maintain purity, stability, and quality of fluids during conveyance because of their stainless steel construction. In addition, they regulate the flow of different materials within the device while continuously disinfecting and cleaning it to keep it tidy.

- Fuel Oil systems

An actuated globe valve is suitable for fuel oil systems to ensure a constant pressure supply to the engine-driven pumps. It acts as a pre-warming bypass to heat the fuel before starting the engine.

Why Valve Plays an Important Role in Throttling?

Valves are crucial in an industrial throttling process since they can do a lot of heavy work. These valves start and stop the processing of a liquid or gaseous substance by turning it on and off. They regulate the flow from one point to the other, i.e., from a place with a higher volume of pressure to a point having a lower quantity of pressure.

It thus provides a continuous flow with assured pressure by leaving the device moderately or fully open. Such valves are vital for throttling because they even help control the direction of fluids and gases, which is crucial for some applications.

A metal butterfly valve used in conventional gasoline engines can intake manifolds to reduce the power output for part-load operation. It typically operates in the fully open or closed position to throttle various media, including clear water. Since the market provides a wide variety of these devices, pick the one with a low-pressure drop, is easy to use, and has a construction that makes the fluid pass through a change of direction.

How to Choose Throttling Valves?

Your decision to purchase a throttling valve for an application depends on many complex factors. One must learn about these parameters and check them thoroughly to zero down on a specific device. You must carefully consider the parameters on which your selection depends. It will let you quickly determine whether the system needs or can accommodate a throttling valve.

It includes the following considerations:

- Temperature

Throttling media often causes an increase in temperature and pressure. So, when selecting a throttling valve, one must refer to the system standards. It helps one know whether the device allows for these fluctuations. If it does not support such changes, you will know it is not ideal for a particular application.

- Size of the Pipes

The larger the pipe, the more limited the capacity of a flange butterfly valve. It is so because as the volume of media flowing through the device increases, regulating flow becomes more difficult for the valve. Another reason size is a critical factor is that larger valves accompany huge components that take up more valuable space in the design.

- Requirement of Flow Control

Since the temperature of the media flowing through the device can alter its flow rate or position, control is often required. It helps maintain a consistent flow rate as required by a piping system. These devices should be able to reduce the media velocity or pressure inside the piping system.

- Construction Material

The material used for constructing the valve must be compatible with the media flowing through it for better handling. It is a critical consideration because certain chemicals found in the substance can erode the valve material with time. So, always check the compatibility of the material with the flowing media.

For instance, at low temperatures, bronze and stainless steel are ideal. But, at extremely high temperatures, ceramic, cast iron, carbon steel, PVC plastic, and refractory metals are suitable.

- Actuation

The actuation offered by a forged ball valve is a vital factor impacting the buying decision. When selecting the device for a particular application, you can choose from a manual and an automatic actuator. Since manual actuators cannot deliver the required throttling accuracy of some applications, automatic ones are better to use in their place.

But before doing so, determine whether a system’s flow pressure needs or can accommodate an automatically actuated valve for precise calibration. Also, don’t forget that a physical actuator cannot provide an accurate and efficient throttling capacity.

- Connections

The availability of the required connections lets one know whether it is possible to adapt the valve to the existing pipeline connection. How the valve attaches to the pipe is crucial because if you have to adjust the system to fit the device, it is certainly not the perfect valve.

Conclusion

People might not realize that valves have played a prominent role in our life for a long time. In the absence of these devices, it might have been tough to carry out industrial work and even our daily household functions. A pneumatic pressure relief valve regulates gaseous and liquid substances by controlling and monitoring the flow through pipelines and other passageways. If you want to make the most of these devices, understand their function and pick the one that suits your purpose.

While some throttling valves are best suited to control the flow of liquids, others are suitable for gases. It is also vital to identify whether the media passing through the device will remain liquid throughout the flow or will vaporize and become a gas. Industrial workers must thoroughly consider these parameters when selecting the best valve for throttling. We hope this blog helps you do so to at least some extent.

If you’re looking for a reliable valve manufacturer in China providing high-quality solutions for various industrial needs, you may contact us.