Introduction to Check Valves

Definition and Basic Function

Staring down at the network of pipes and valves sprawling like a metallic jungle in the heart of the plant, one can’t help but marvel at the ingenuity of human design. Among these engineering feats, the check valve, unassuming as it may seem, plays the pivotal role of directing traffic in the bustling city of fluids. Like a seasoned cop at a busy intersection, the check valve ensures the flow of fluids in one intended direction, preventing the chaotic reverse flow that could spell disaster for the system.

How Check Valves Operate

Diving a bit deeper into their operation, these valves automatically respond to the fluid pressure and velocity. They swing open when the forward flow pressure exceeds the cracking pressure—the minimum upstream pressure required to open a valve. Once the flow ceases or reverses, they swing back to their closed position. This dance is not orchestrated by any external mechanism but by the pressure of the fluid and flow direction—quite an elegant solution, wouldn’t you agree?

What Does a Check Valve Do in Fluid Systems?

In every industrial setup, check valves are key, like a conductor making sure each note is hit just right. Let’s take a closer look at what they do in fluid systems.

Preventing Backflow and Its Importance

Picture a highway where cars zoom one way. Now, think of one car going the wrong way—a total mess, right? That’s the kind of trouble reverse flow can cause in a fluid system. Check valves are like the traffic guards here, firmly stopping the wrong-way flow and keeping our systems clean and running right.

Protecting Equipment from Damage

Moving on from their role as backflow blockers, let’s look at how check valves keep gear from getting wrecked. By managing how the fluid moves, these valves protect pumps and machines from harm. For example, a study showed that putting in check valves cut down equipment failure by 75%, highlighting how they’re critical in keeping everything downstream safe and preventing major problems like blowouts. They’re not just about controlling flow; they’re about keeping the whole setup working well and safely for a long time.

Maintaining System Pressure

Next, check valves also do a great job at keeping system pressure just right. They’re like the door staff at a club, letting just enough pressure in. If the pressure’s too much or not enough, they close up, stopping energy waste and making sure fluids move the right way with no drips or leaks. This careful balance is what keeps our systems in top shape and dependable.

As we move on to the different kinds of check valves, it’s clear they’re not just bits of metal in pipes. They’re the quiet guards, the watchful keepers, and the smooth operators that keep our industrial actions humming along.

Types of Check Valves

After we have basic knowledge about what check valves can do, let’s dive into the common types that keep things flowing in the desired direction.

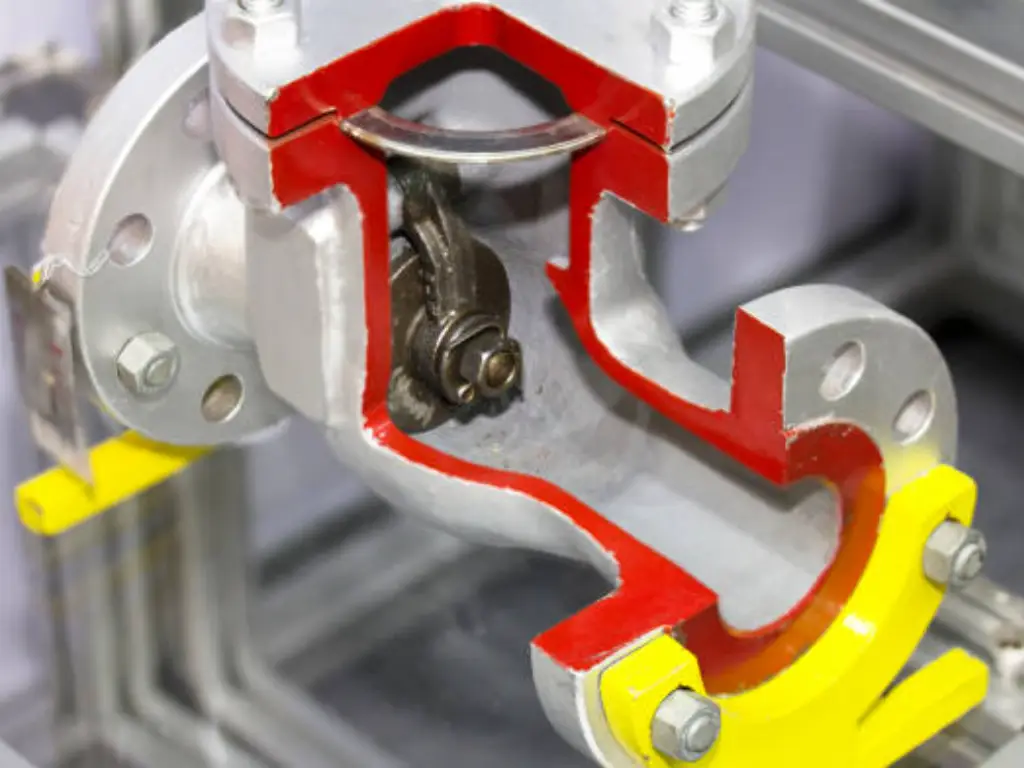

Swing Check Valves

Swing check valves are the stalwarts of the valve family. Picture a heavy-duty door that only swings one way; that’s your swing check valve. It boasts a robust valve body that houses a disc, swinging open to let fluids pass and shutting tight to stop any reverse flow dead in its tracks. They’re a breeze to install and maintain, making them a go-to for large-diameter piping systems where the stakes are high and the flow must go on.

Non-Slam Check Valves

Transitioning to non-slam check valves, these are the unsung heroes in the battle against the dreaded water hammer. This phenomenon, akin to a hydraulic shock wave, can wreak havoc in a piping system. Non-slam check valves counter this with a swift and smooth closure, ensuring that the only bang in the pipes is the sound of efficiency. They’re a fixture in industries where the flow is as fast-paced as the market itself—think oil, gas, and power generation.

Lift Check Valves

Now, let’s talk about lift check valves. These little geniuses use a disc that lifts to allow flow and sits back down when it’s time to stop. They’re like the efficient elevators of the valve world, perfect for both gases and liquids. Dombor’s lift check valves, with their versatile designs, can fit snugly into any system, be it horizontal, vertical, or at an angle, adapting to the needs of the moment.

Tilting Disc Check Valves

And finally, the tilting disc check valves. These are the acrobats of the valve circus, flipping open with even the slightest inlet pressure and sealing shut just as quickly to prevent any backsliding of fluid. Their high-temperature endurance makes them ideal for the chemical refining industry, where reactions are hot and the flow must not falter.As we pivot from the mechanics to the application of check valves in various industries, it’s clear that each type of check valve is a tailored fit for specific scenarios. The right valve type can mean the difference between a smooth operation and a full-stop.To encapsulate the unique features and industrial applications of such valves, here’s a table that paints a clear picture:

| Valve Type | Key Feature | Common Industry Applications |

| Swing Check Valves | Prevents reverse flow | Water distribution, large pipelines |

| Non-Slam Check Valves | Reduces water hammer | Oil, gas, power generation |

| Lift Check Valves | Versatile positioning | Gas or liquid transport |

| Tilting Disc Check Valves | Quick open/close, high-temperature tolerance | Chemical refining |

In the realm of check valves, the choice is clear: select the valve that speaks to your system’s needs, and you’ll have a flow that’s as reliable as the dawn.

Check Valves in Different Industries

Water Treatment and Management

In water treatment plants, check valves are like silent sentinels, ensuring that clean water flows forward to our homes while preventing contaminated water from creeping back into the system. Their role is vital in maintaining the integrity of our water supply.

Oil, Gas, and Chemical Industries

In the veins of our modern energy lifelines—the oil, gas, and chemical sectors—check valves ensure that the flow of fluids remains uninterrupted and secure, much like security checkpoints protect the well-being of a bustling metropolis.

HVAC Systems and Their Requirements

HVAC systems, with their intricate balance of heating, cooling, and ventilation, rely on check valves to maintain climate control with surgical precision. They are as crucial to building management as a thermostat is to a homeowner on a chilly winter evening.

Addressing Water Hammer with Check Valves

What is Water Hammer?

The water hammer, with its ominous name, is the shockwave that reverberates through pipes when a fluid in motion is forced to stop or change direction suddenly. This phenomenon can cause tremors within a system, like thunder shaking the foundations of a house.

How Check Valves Mitigate Its Effects

The right check valve acts as a shock absorber, dampening the tremulous aftermath of a water hammer. It’s a preventative measure, much like a surge protector for our electronic devices.

Selecting the Right Check Valve

Choosing the right check valve is like picking the perfect player for your team; it needs to fit the game plan perfectly. Let’s break down what to consider to make the best choice for your system.

Installation Considerations: Orientation and Positioning

It’s not just about plugging in a check valve and calling it a day. You’ve got to think about where it’s going. Like a puzzle piece, it has to fit just right. Whether you’re working with a vertical or horizontal pipeline, the valve must align with the flow direction and the dynamic pressure of the system. Take, for example, a rubber diaphragm check valve in a vertical line; it needs enough pressure from the fluid flow to open properly. If the pressure differential is off, it’s like trying to fit a square peg in a round hole—it won’t work.

Material Compatibility and Selection

The stuff your check valve is made of matters a lot. If your fluid is more corrosive than a bad mood on Monday, you’ll need something like stainless steel to handle it. Say you’re dealing with high-temperature oils; a PVC valve would throw in the towel faster than you can say “meltdown.” So, you pick a material that can take the heat and keep on ticking. It’s about matching the valve’s guts to the job at hand.

Cost-Benefit Analysis

Money talks, but so does quality. High-end check valves might make your wallet wince, but they bring their A-game to performance and longevity. It’s like buying a pricey pair of boots that last years versus cheap ones that give up in a month. You’ve got to weigh the upfront cost against the long-term benefits. Will the valve save you from frequent fixes and downtime? If yes, then it’s worth the extra dough.In the end, picking the right check valve is about balancing the books while ensuring your fluid flow is as smooth as a jazz tune. It’s a bit of a juggling act, but get it right, and your system will be all the better for it.Got questions about picking the right valve? Hit us up! Our team of experts is ready to hook you up with the perfect fix. We’ve got your back with various types of check valves and more!

Conclusion: What is a check valve used for?

Check valves are unsung heroes in our industrial landscapes—silent and steadfast. From the sprawling networks of our water supply to the intricate workings of power plants, they are the sentinels in the shadows, ensuring that every drop of fluid moves in harmony with the intended flow direction. These critical components may be small, but their role is as vast as the systems they protect—indispensable, unwavering, and integral to the world as we know it.