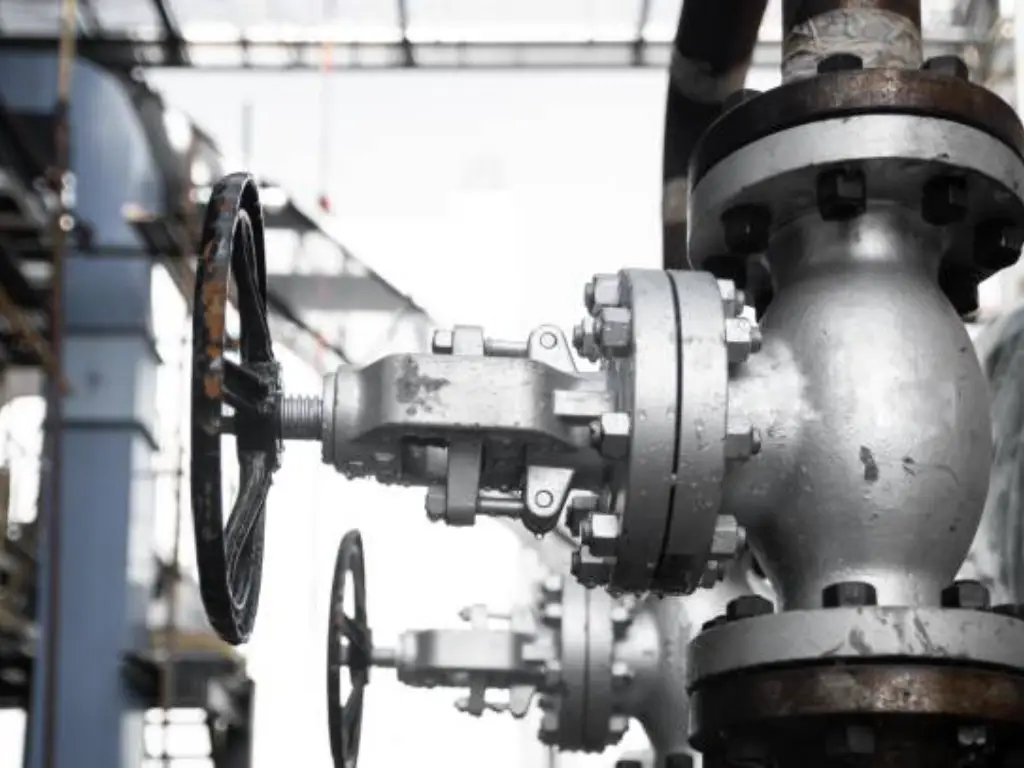

In industries like oil and gas, chemical processing, and water treatment, the ball valves’ heaviness is always a significant factor affecting their production operations. The weight of these valves affects system design, installation and maintenance, thus the need for understanding by manufacturers. This article will provide a comprehensive analysis on ball valve weights to help you understand more about them.

Why Is Ball Valve Weight Important?

It is crucial to engineering and industrial applications that a ball valve has the right weight. Below are some of the most important reasons for knowing the weight of a ball valve:

- Structural Support

Some ball valves can be quite heavy, particularly in larger sizes and strong materials like carbon steel and stainless steel. Since these valves are heavy, they must be supported structurally within the system. If not properly supported, this could lead to pipeline instability with possible failures or safety hazards occurring. Hence, it is important that system stability can be maintained by ensuring support structures can handle the weight of such valves.

- Installation and Maintenance

Installation and maintenance become challenging when dealing with heavier ball valves. Typically, this necessitates specialized equipment for lifting and positioning, making such procedures more complicated and expensive. Furthermore, it becomes harder to lift them manually due to their heaviness thereby increasing chances of worker injuries resulting from inappropriate handling methods. Consequently, understanding how much a valve weighs helps one in coming up with well-coordinated safe installation as well as efficient maintenance procedures.

- System Performance

Ball valve weight has an impact on system performance in terms of pressure class and flow rate. Heavier valves can change the fluid flow dynamics and pressure distribution within the system. This is particularly important for high-pressure services as the valve should be able to withstand substantial forces without compromising its performance. To this end, it is vital for engineers to pay attention to the weight of such equipment while planning their smooth and efficient operation.

- Selection of Actuators and Accessories

The selection of appropriate actuator and other accessories depends on the ball valve’s weight. A heavier valve requires a more substantial actuator to function properly. It should operate smoothly during opening and closing processes that do not wear out the entire system excessively. By knowing the weight, one gets to choose compatible components to ensure that they last long enough before requiring replacements or repairs.

Key Factors Influencing Ball Valve Weight

Several crucial factors determine how heavy a ball valve will be. The knowledge of these factors helps engineers to choose the right valve for their particular applications and guarantees optimal performance of system. Considerations for primary purposes are highlighted as follows:

1. Valve Size

The weight of a ball valve is significantly influenced by its size as larger valves need more material for their fabrication. For instance, a 4-inch valve would weigh more compared to a 1-inch valve due to additional amount of material required in ensuring that structural integrity and durability is maintained. Moreover, valves with bigger internal bores have thicker walls and more elaborate parts which therefore add up on their weights so that they can bear the operating pressures and stresses.

2. Valve Material

Another critical factor in the determination of weight is the type of material that constitutes the ball valve. Common materials employed include carbon steel and stainless steel. Carbon steel valves are usually heavier as a result of higher density and strength. On the other hand, stainless steel valves may be lighter depending on how they were constituted even though they still remain strong enough. Other materials like bronze, brass, different alloys can also affect it since each has its own density and properties.

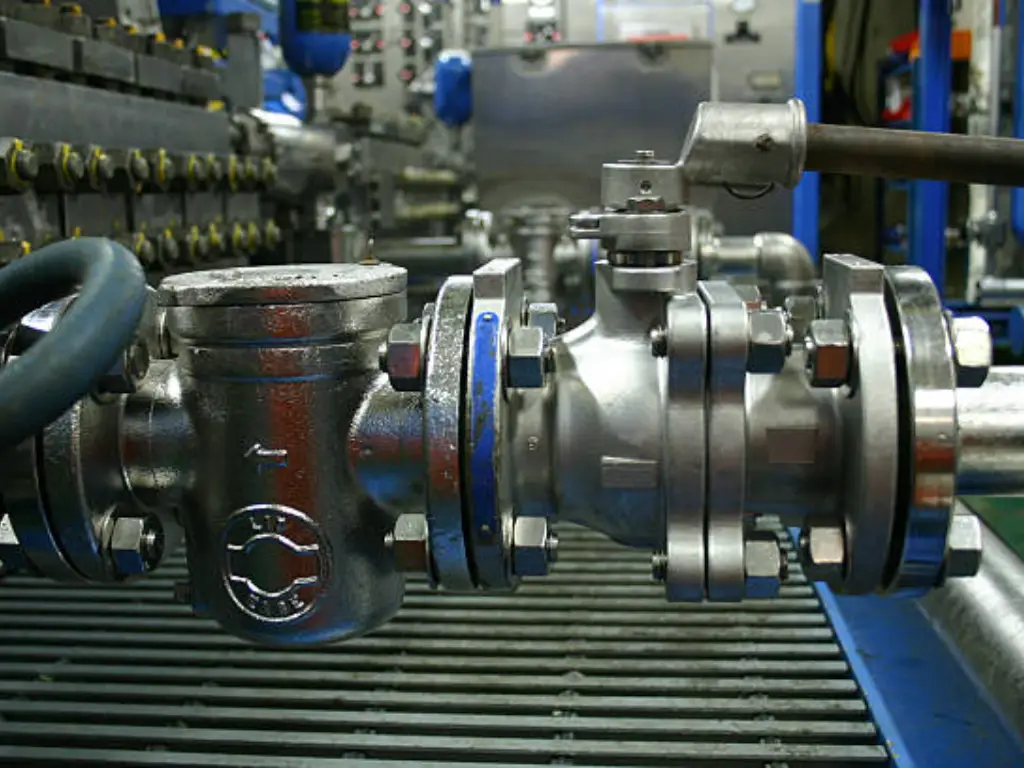

3. Valve Type

The kind of valve also influences how much it weighs. For example, trunnion mounted ball valves are heavier than floating ball valves because they have more parts to hold up the ball. Besides this, what determines the weight is whether it is full port or reduced port valve and design and construction of the valve. Higher amount of material used in making full-port valves makes them heavier since they must accommodate larger internal diameters.

4. End Connection Type

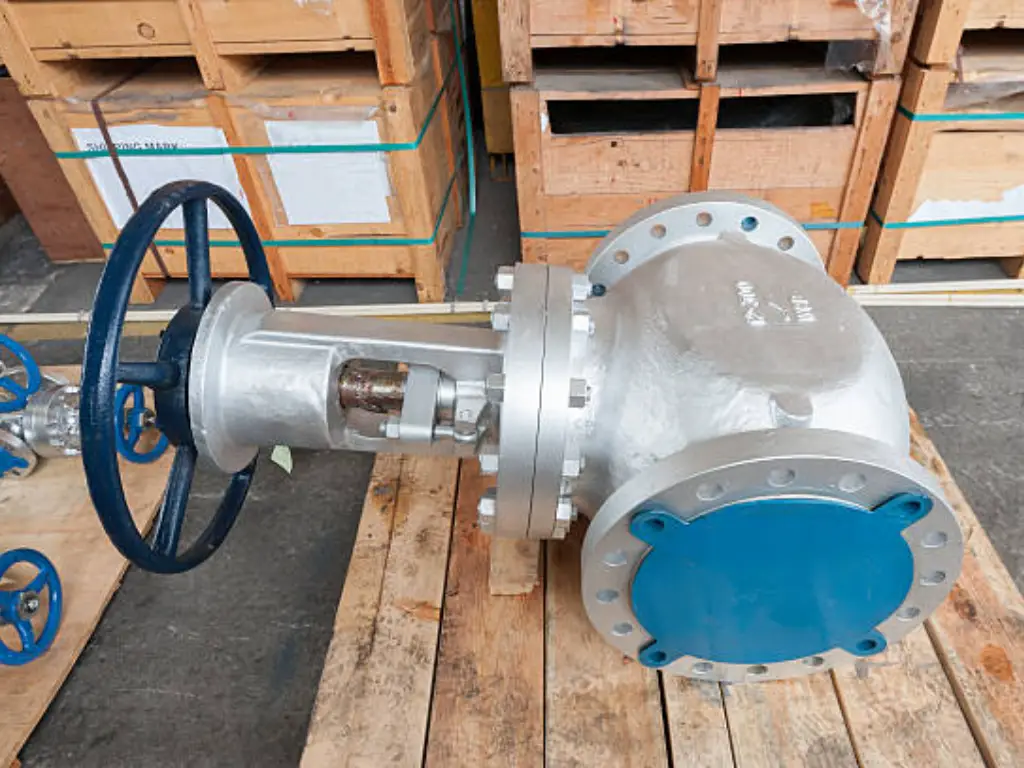

Moreover, the type of end connection can either add to or reduce the overall weight of a given valve. In connection with this point, butt welding ended valves may be made with thicker materials used for welding thus making them relatively heavier compared with other types such as flanged, threaded and socket weld.

5. Pressure Class

The weight of a valve is also influenced by its pressure class. Since valves with ability to handle intense pressure should have more solid walls and be constructed with strong materials, they tend to weigh more. Heavier valves must be used for higher pressure classes such as those provided in API and ASME standards so that safety and reliability under high-pressure conditions can be guaranteed.

6. Actuator and Accessories

The presence of an actuator as well as other accessories may increase the weight of a ball valve. The size or type of actuators affect its additional mass while automating operation. There are different weights for pneumatic, hydraulic and electric actuators employed here.Other accessories like positioners, limit switches, and manual overrides also tend to increase overall weight in most cases.

Engineers must understand these important factors in the selection of ball valves for specific applications. By considering valve size, valve material, valve type, end connection type, pressure class and any other accessories that may be present, it can be assured that the selected valve will meet operational requirements and maintain system integrity.

Ball Valve Weight Chart: A Detailed Reference by Size and Type

For accurate system design and selection, it is important to have a good knowledge of the weight of different types of ball valves depending on their sizes and materials. The table below provides a detailed reference chart on two types of ball valves: Trunnion-Mounted Ball Valves and Floating Ball Valves. The data used in this table are from trusted valve manufacturers and industry standards.

Trunnion-Mounted Ball Valves

| Size (Inch) | Material | Weight (kg) |

| 2″ | Carbon Steel | 31 |

| 2″ | Stainless Steel | 24 |

| 3″ | Carbon Steel | 54 |

| 3″ | Stainless Steel | 43 |

| 4″ | Carbon Steel | 99 |

| 4″ | Stainless Steel | 81 |

| 6″ | Carbon Steel | 272 |

| 6″ | Stainless Steel | 226 |

| 8″ | Carbon Steel | 544 |

| 8″ | Stainless Steel | 444 |

| 10″ | Carbon Steel | 771 |

| 10″ | Stainless Steel | 625 |

| 12″ | Carbon Steel | 997 |

| 12″ | Stainless Steel | 807 |

Floating Ball Valves

| Size (Inch) | Material | Weight (kg) |

| 1/2″ | Carbon Steel | 3.5 |

| 1/2″ | Stainless Steel | 3.5 |

| 3/4″ | Carbon Steel | 5 |

| 3/4″ | Stainless Steel | 5 |

| 1″ | Carbon Steel | 7.5 |

| 1″ | Stainless Steel | 7.5 |

| 2″ | Carbon Steel | 23 |

| 2″ | Stainless Steel | 23 |

| 3″ | Carbon Steel | 48 |

| 3″ | Stainless Steel | 48 |

| 4″ | Carbon Steel | 80 |

| 4″ | Stainless Steel | 80 |

| 6″ | Carbon Steel | 94 |

| 6″ | Stainless Steel | 94 |

Practical Considerations for Engineers When Selecting Ball Valves Based on Weight

There are few things that should factor into engineers’ choices of ball valves in terms of weight so that their performance and the integrity of systems can be optimal. The following are the main considerations:

- Application Requirements: The specific demands placed on an application will have a lot to do with determining which kind of ball valve best suits it. In cases such as those in the oil and gas industry where high pressures are involved, trunnion mounted ball valves could perhaps prove heavier due to their strong make, which makes them capable of standing higher forces. Conversely, lighter floating ball valves could be more appropriate for this service when frequent maintenance is required or if weight is a concern.

- Material Selection: The material used to construct the ball valve affects its weight considerably. Common materials include carbon steel and stainless steel, where carbon steel is normally heavier than stainless steel. While carbon steel has good strength and durability, stainless steel offers better corrosion resistance, which is critical in chemical processing and water treatment industries among other fields. Therefore, depending on environmental condition it operates under, engineers need to consider corrosion resistance vs weight against durability and strength.

- Valve Size and Type: The size of a valve depends directly on its weight as well as whether it is a float operated or fixed type of ball valve which also determines its massiveness as well. Trunnion-mounted valves tend to be heavier simply because they have other parts with them that provide stability and support for large-scale installations and high pressure systems too. Engineers should choose size and type appropriately based on flow requirements within the system while considering pressure ratings too.

- Installation and Maintenance Considerations: Installation and maintenance processes can be difficult with heavier ball valves which require a more rigid support structure. Availability of lifting equipment is one thing that engineers need to consider during the installation process where these valves should be upraised and positioned in place. Lighter valves can however simplify these processes but may require frequent replacement if they wear out quickly.

- System Design and Support: The weight of the ball valves must be taken into account in the overall system design. This implies ensuring that the piping as well as support structures can bear the extra load without compromising its integrity. Inadequate support can lead to misalignment, increased wear and tear or even catastrophic failures. Engineers have to develop supports not only carrying weight but providing stability under operational condition.

- Cost Implications: Weight can affect both the cost of the valve itself and that of the entire system as well. More solidly made heavier valves tend to cost more especially if they are made from stronger materials. Additionally, installations expenses go up due to expensive specialized equipment used by technicians during mounting or repairing them while various manufacturers propose different service life’s products at differential prices. Engineers should balance upfront costs against durability, reliability, reduced frequencies of repairs among other long-term benefits.

- Environmental and Regulatory Compliance: Some industries have specific regulations on materials used or construction types for valves which may influence weight. Compliance with standards such as API, ISO, ASME confirms that chosen valves meet safety and performance criteria but it can add weight because those standards specify certain design requirements.

The right ball valve selection based on weight involves examining application requirements in view of valve size, system design, material properties, installation and maintenance needs, cost implications and regulatory compliance. By taking into account these things engineers can make choices which will enhance system performance and reliability.

Best Practices for Handling and Installing Heavy Ball Valves

Careful planning and execution are necessary for handling and installing heavy ball valves to enhance safety and efficiency. Here are some best practices to follow:

Use Appropriate Lifting Equipment

Appropriate lifting equipment such as cranes, hoists, or fork lifts should be used when handling heavy ball valves. Make sure that the equipment is rated for the weight of the valve and is in good working condition. Proper use of lifting slings can help prevent accidents by securing the valve properly. Always follow the manufacturer’s recommendations for lifting and handling.

Ensure Secure Support and Alignment

Make certain that support structures are prepared adequately enough to handle the weight of a ball valve before installation. This involves inspection of support beams, brackets, mounting platforms strength and stability. Proper alignment prevents stress on both the valve and piping system. Leaks can occur from misalignment leading to wear and potential failure. Use an alignment tool to verify proper positioning of the valve in relation to pipeline.

Plan for Safe Handling and Positioning

Develop a detailed plan for handling and positioning the ball valve during installation. This plan should include the steps for moving the valve from storage to the installation site, lifting it into place, and securing it. Consider the pathway, potential obstacles, and the team members involved. Communication is key in accidents prevention thus need to coordinate properly with everyone as they must be informed always about what they are required to do.

Follow Manufacturer’s Installation Guidelines

You should strictly adhere to manufacturer’s guidelines for installation. These guidelines have been developed to ensure proper operation of the valve as well as its security. Such recommendations may also entail bolt torque settings, lubrication points or how exactly to secure the valve. If ignored then such guides might lead to wrong installation, which may result in operational challenges or safety risks.

Regular Maintenance and Inspection

After setting up, valve will be required to undergo frequent repair and checking services so as to make it last longer and provide its best performance. Make sure you check for such signs on a regular basis as wears, corrodes or leaks. All the movable parts must be well oiled while the valve should operate well when in use. If there are any problems, they should be attended immediately for prevention of major problems occurring. Maintenance records should be kept with much care to track upon valve’s behavior and identify re-occurring issues.

These measures will enable engineers and technicians safely handle and install heavy ball valves without compromising system reliability and performance over time. Proper planning, using correct tools, following instructions, observing maintenance schedules are crucial for successful handling as well as installation activities.

Final Thoughts

This article examines the main factors that affect the weight of ball valves such as their size, material and type. We have provided an extensive chart which displays weights for two kinds of ball valves, trunnion-mounted and floating ball valves, across different sizes and materials. Also, we looked at some practical issues to be taken into consideration by engineers when examining valve weights and giving the best methods to use while dealing with them or putting up heavy ball valves.

Would you like to optimize your system using the appropriate ball valves? Contact us now for professional advice and quality valves!