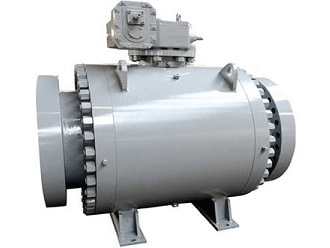

APD 6D Ball Valve Standard: What does it mean?

The API 6D specification, given by the American Petroleum Institute (API), is an international standard for pipeline valves. It covers the requirements and recommendations on how ball, check, gate, and plug valves undergo design, manufacturing, testing, and documentation for their application in pipeline systems. API 6D is the main specification applied for valves in pipeline service.