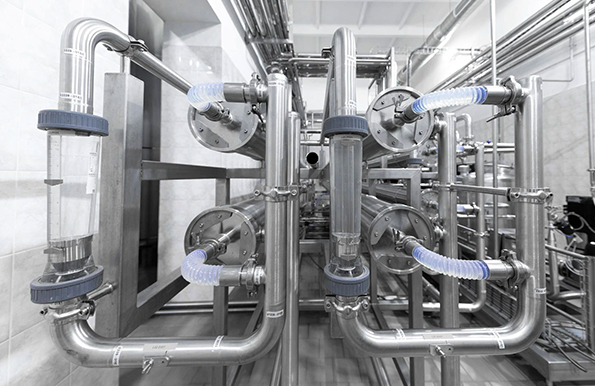

Water treatment technology is critical to ensure the water consumed is clean, safe, and toxins-free. It is used to clean, disinfect, and purify water.

Understanding the fundamentals of water treatment technology is critical for anyone who wishes to consume safe, clean water. This is part of understanding the various types of water treatment equipment available, how they work, and the need to maintain them.

This guide will introduce consumers to the fundamentals of water treatment equipment. Such as the many types of equipment, how they work, and how important it is to maintain them.

It will also offer tips on how to select the best water treatment equipment based on factors such as water supply, water quality, and flow rate. In addition, it is important to note that choosing the right industrial ball valve supplier can have a significant impact on the success of water treatment operations.

What Is a Water Treatment System

A water treatment system is a method or set of operations that purifies and cleans water to be safe for human consumption or other applications. Physical, chemical, and biological treatments, as well as filtration and disinfection procedures, can all be included in these systems.

The treatment procedures utilized will be determined by the source water’s quality and the planned use of the treated water. Some popular water treatment processes include coagulation, sedimentation, filtration, and disinfection.

A water treatment system’s purpose is to eliminate pollutants and toxins from water, such as bacteria, viruses, and chemicals, to improve the water’s overall quality and safety.

A water treatment distribution is also a collection of techniques used to filter and clean water to be safe for human consumption or other applications. The treatment procedures utilized will be determined by the source water’s quality and the planned use of the treated water.

Furthermore, a water treatment system’s purpose is to eliminate pollutants and toxins from water, such as bacteria, viruses, and chemicals, to improve the water’s overall quality and safety.

Types of Water Treatment Equipment

Water treatment equipment helps to purify water so that it can be safely used for drinking, irrigation, and other activities. Different types of equipment are available to address different levels of contamination in the water.

Industrial Valves

Industrial valves are an important component of the water treatment process, as they control the flow of water in the system, regulate pressure, and direct water to various stages of treatment. Some common types of industrial valves used in water treatment include:

- Gate Valves: These are used to regulate the flow of waters in and out of the treatment system.

- Globe Valves: Used to control the pressure and flow rate of water within the treatment system.

- Industrial Ball Valves: Used for quick shutoff and isolation of the water flow.

- Butterfly Valves: Used for throttling flow in the treatment system.

- Check Valves: Used to prevent backflow and ensure water flows only in the intended direction.

- Diaphragm Valves: Used for applications where the water may be corrosive or abrasive.

By properly regulating the flow of water in the treatment system, industrial valves help to ensure that the water is effectively and efficiently treated, meeting the required quality standards before it is returned to the environment or reused.

The choice of the industrial valve will depend on the specific requirements of the water treatment process, including flow rate, pressure, and temperature.

Sedimentation Tanks

Sedimentation tanks, also known as clarifiers, are a common type of water treatment equipment used to remove suspended solids from water. Sedimentation works by enabling solids to settle to the tank’s bottom, where they can be removed.

In a sedimentation tank, water is fed into the tank and allowed to flow slowly through the tank. The water velocity is carefully controlled to ensure that the solids have enough time to settle to the tank’s bottom.

Over time, the solids will settle to the bottom and form a sludge, which can be removed through a sludge outlet. The clear water is then collected from the top of the tank and can be further treated as needed.

Sedimentation tanks are commonly used in municipal and industrial water treatment plants to remove suspended solids from raw water sources, such as rivers or lakes. The tanks can be designed to handle a wide range of flow rates, making them suitable for use in large and small water treatment systems.

Filtration Systems

Filtration systems in water treatment are essential to ensure the safe and clean use of water resources. There are many types of filtration systems used in water treatment, each designed to remove different contaminants from water sources. These systems can be classified into two main categories: mechanical and chemical filtration.

Mechanical filtration is a process that involves the physical removal of particles from water sources, either directly or through a medium such as sand, charcoal, or other materials.

Chemical filtration is a more complex process than mechanical filtration, involving the use of chemicals or other compounds to remove specific contaminants from water sources. This type of filtration is most effective for removing organic materials, heavy metals, and other toxic components from water sources.

Disinfection Equipment

Disinfection equipment is used in water treatment to kill harmful microorganisms, such as bacteria, viruses, and parasites, that may be present in the water. The goal of disinfection is to reduce the risk of waterborne illnesses and ensure that the treated water meets the required quality standards.

There are several types of disinfection equipment used in water treatment, including, chlorine disinfection, Ultraviolet (UV) disinfection, and Ozone disinfection.

Each type of disinfection equipment has its own strengths and weaknesses, and the specific type used will depend on the quality of the water being treated, the required quality of the treated water, and other factors such as cost and ease of operation.

Softening Equipment

Softening equipment in water treatment refers to devices used to remove excess hardness ions, such as calcium and magnesium, from water. The most common method of softening is ion exchange, where the hardness ions are exchanged with sodium ions.

Other methods include lime-soda ash treatment and reverse osmosis. The choice of softening equipment depends on the desired level of softening, the size of the treatment facility, and the water quality.

Softening equipment is important in water treatment because hard water can cause scaling in pipes, damage to appliances, and affect the efficacy of soap and detergents.

Membrane Systems

Membrane systems refer to devices that use a thin barrier, or membrane, to separate contaminants from water. The most common types of membranes used in water treatment are microfiltration, ultrafiltration, nanofiltration, and reverse osmosis.

Membrane systems are commonly used in various water treatment applications, including desalination, removal of dissolved solids and impurities, and production of high-purity water.

The choice of membrane system depends on the type and level of contaminants present in the water, the desired quality of the treated water, and the size of the treatment facility.

Mixers and Aerators

Mixers and aerators in water treatment are devices used to increase the rate of chemical reactions and enhance the oxygen transfer in water. Mixers are used to agitate the water and maintain its homogeneity. They are typically used to evenly distribute chemicals and ensure proper mixing of coagulants, flocculants, and other treatment chemicals in the water.

While aerators are used to transfer oxygen into the water to support the growth of beneficial bacteria, which are used in the treatment of wastewater. Aerators can also help with the elimination of dissolved gasses like carbon dioxide.

The choice of mixers and aerators depends on the type and level of contaminants in the water, the desired quality of the treated water, and the size of the treatment facility. Flow rate, water temperature, and the presence of other chemicals in the water all play a role in selecting the best mixer and aerator technology.

Clarifiers

Clarifiers in water treatment are devices used to remove suspended solids, algae, and other impurities from water. They work by allowing the impurities to settle into the bottom of a tank, where they are removed.

Clarifiers can be equipped with mixers and aerators to improve their performance. They are commonly used in water treatment plants for sedimentation, coagulation, and flocculation processes.

The choice of clarifier technology depends on the type and level of contaminants in the water, the desired quality of the treated water, and the size of the treatment facility.

What Are the Process of the Water Treatment System

Public drinking water systems employ several water treatment procedures to provide drinkable water to the public. Water treatment stages often used in public water systems include flocculation, coagulation, filtration, sedimentation, and disinfection. The followings are the water treatment process or steps.

Coagulation

Coagulation is typically the first stage in water treatment. Positively charged chemicals are introduced to water during coagulation. The positive charge neutralizes the negative amount of dissolved dirt and other particles.

When this happens, the particles interact with the chemicals to form slightly larger particles. Salts, aluminum, and iron are this stage’s most commonly used chemicals.

Flocculation

Following coagulation, there comes flocculation. Flocculation is gradually mixing water to produce larger flocs and heavier particles. Water treatment tools facilities frequently add chemicals during this step to aid floc development.

Sedimentation

Water treatment plants employ sedimentation as one of the procedures to remove particles from water. Flocs drop to the bottom of the water during sedimentation because they are heavier than water.

Filtration

Following the sinking of the flocs to the bottom of the sea, the clean water on the surface is filtered to eliminate any remaining particles. During filtration, clean water passes through filters of diverse particle sizes and materials such as sand, gravel, and charcoal.

These filters remove dust, chemicals, parasites, bacteria, and viruses from dissolved particles and pathogens. Furthermore, activated carbon filters reduce unpleasant odours.

Water treatment facilities may use ultrafiltration in addition to or instead of traditional filtration. Water is ultrafiltered through a filter membrane with extremely small pores. Only water and small molecules, such as salts and tiny, charged molecules, can flow through this filter.

Another filtration technology that eliminates extra particles from water is the reverse osmosisexternal icon. When processing recycled water, water treatment plants frequently use reverse osmosis. In addition to its other names, “reclaimed salt water” also goes by the moniker “water for drinking.”

Disinfection

After the water has been filtered, water treatment facilities may add chemical disinfectants such as chloramine, chlorine, or chlorine dioxide to kill any remaining parasites, bacteria, or viruses. Water treatment plants will guarantee that the water leaving the treatment plant has low amounts of chemical disinfection to help keep water safe as it goes to homes and businesses.

This residual disinfectant kills microorganisms in the pipes that connect the water treatment plant to the faucet. According to a study, this is the case. Although UV light and ozone are excellent in disinfecting water in the treatment plant, they do not continue to destroy bacteria as the water travels down the pipes to the tap.

It is important to source industrial valves from a trusted industrial valve manufacturer, as the quality of the valves used in the water treatment system can greatly impact the efficacy of the treatment process.

What Industries Need Water Treatment Equipment

Wastewater treatment is an essential practice in a variety of industries. Companies must act responsibly to preserve the earth’s health and the safety of human populations.

Every day, the average American home uses roughly 300 gallons of water. Around 70% of this utilization occurs indoors. Outdoor water consumption accounts for 30% of total residential water use in the United States, but it can be much higher in desert regions and water-intensive landscapes.

Businesses should not treat their wastewater in many cases. They may lack the required permits, and the procedure may be too hard to carry out without significant expenditures.

A professional wastewater treatment facility has the necessary licenses, experience, and technical skills to treat and dispose of industrial wastewater in an affordable, efficient, and, most importantly, safe manner.

The following is the list of industries that need water treatment:

Agriculture

Water is used in agriculture for irrigation, watering cattle, and cleaning equipment. Agricultural wastewater often contains high quantities of phosphate and nitrate pollutants, as well as chemical compounds from herbicides and pesticides, due to the use of fertilizers. To ensure that the pollutants are removed from the wastewater, an industrial strainer can be used to filter out any large debris or contaminants before they reach the wastewater treatment facility.

Specialized agricultural operations may produce various forms of wastewater; for example, dairy waste often contains dissolved sugars, fats, and additives. An industrial strainer can be used to help reduce the contaminants in this type of waste before it is treated and disposed of properly.

Chemical Manufacturing

When it comes to the water management equipment treatment of its wastewater effluents, the chemical industry faces major difficulties in complying with environmental regulatory requirements. Traditional pollutants such as oil and grease, as well as suspended particles, ammonia, chromium, phenols, and sulphides, are emitted by petroleum refineries and petrochemical industries.

Power Plants

In particular, power plants that use coal are a substantial source of industrial wastewater. Many of these factories emit wastewater containing high levels of metals such as mercury, clead, cadmium, and chromium, and selenium, arsenic, and nitrogen compounds (nitrates and nitrites). Plants with air pollution controls, for instance, wet scrubbers, dump the pollutants they capture into the wastewater stream.

Food Processing

Pesticides, insecticides, animal waste, and fertilizer concentrations in food and farm wastewater must be monitored. Food processing from raw materials generates fluids with high amounts of particulate particles, soluble organic waste, or chemicals.

Organic waste from animal slaughter and processing, bodily fluid, intestinal matter, and blood are all sources of water pollutants that must be treated.

Construction

In addition to substantial debris waste, the construction industry produces wastewater in various ways. The washing of heavy construction equipment can generate effluent, which construction companies must manage adequately. Furthermore, using chemicals such as paints, solvents, and adhesives generates wastewater, which firms must properly dispose of.

Industrial Manufacturing

Industrial manufacturing facilities, such as iron and steel mills, generate wastewater through various operations. Massive amounts of cooling water are required in blast furnaces to produce iron from ores, which can get contaminated with byproducts such as ammonia and cyanide.

Water is required for steel production activities as a coolant and lubricant. Industrial establishments may produce significant amounts of oil waste and create substantial quantities in their effluent.

Oil and gas

Cleaning water and oil waste are generated as wastewater by the oil and gas industry, specifically oil and gas extraction. Both the remnants in the tanks and the water used to clean them must be properly disposed of.

Water used to clean heavy machinery generates wastewater, which must be disposed of according to municipal, state, and federal regulations. Some forms of old oil can be recycled. If this is the case, a reputable garbage removal company can help oil and gas companies examine their waste recycling options.

Pharmaceutical Production

The pharmaceutical industry generates wastewater during the manufacturing process. Pharmaceutical production waste includes both regulated and residual medicine waste and noncontrolled and nonresidual drug waste. The water used to manufacture the drugs is also discarded.

How to Choose the Right Water Treatment Equipment

Choosing quality industrial valves in water treatment play a critical role in regulating the flow and pressure of water, maintaining the optimal flow rate, ensuring the safety and isolation of individual components, reducing energy consumption, and protecting the public and the environment. Their proper selection and maintenance are essential for ensuring the quality and safety of the treated water.

When selecting wastewater treatment plant equipment, there are various aspects to consider. Here are three critical points to bear in mind:

Examine The Treatment Goals

Begin by considering one’s therapy goals. The company owner or a water treatment specialist can limit the choices by asking the following questions:

- What are the effluent discharge specifications?

- What needs to remove from the wastewater?

- What volume of wastewater must be treated?

- What are the wastewater treatment policies?

The treatment objectives should be the deciding aspect in picking the suitable equipment list for the wastewater treatment facility. Once the treatment goal is determined, company owners may start considering the budget.

Consider the Size of The Treatment Facility

The size of the wastewater treatment facility will also influence the equipment once chosen for the wastewater treatment plant. A smaller wastewater treatment facility might not need as much equipment as a larger one.

When choosing wastewater treatment plant equipment, consumers must also consider the layout of their facility. For example, having a small footprint, compact wastewater treatment plant equipment may be required.

Building a 3D model of the wastewater treatment plant is a low-cost methods of distribution of water for determining the treatment facility size while keeping the budget in mind. This will give anyone a fair idea of how much it will cost and it’s needs.

Think About Budget

It is critical to consider the budget when purchasing equipment for a wastewater treatment facility. If the budget is restricted, business owners may want to use certain types of wastewater treatment plant equipment over others.

Company owners might save money, for example, by choosing wastewater treatment plant equipment adapted to their specific wastewater treatment needs. For example, if the primary treatment methods of water distribution system is effective, it may be able to get by with a smaller secondary treatment system.

A preliminary estimate of the wastewater treatment plant’s costs can help one to stay within the budget while meeting the wastewater treatment goals.

Conclusion

Water treatment equipment is essential to ensuring a clean and safe water supply. Understanding the fundamentals of water treatment equipment and the various types of equipment available is critical for making informed decisions.

For customers needing industrial valves for water treatment equipment, China valve manufacturer Dombor is an ideal alternative. They provide effective industrial valve solutions for managing the flow of diverse mediums such as water, oil, chemicals, and gas.

Dombor is a dependable and trustworthy partner for any organization needing water treatment equipment because of its commitment to offering high-quality, bespoke valves. Each Dombor valve is manufactured using a tight quality assurance system and is adapted to specific industry and media requirements, ensuring that their valves can withstand high pressure, high temperatures, and corrosive substances.