In this modern time of control valves, multiple configurations exist that will strongly regulate the course of pure liquids. Yet, if the liquid includes concrete, the procedure evolves additionally problematic. These pure liquid hydrants are never a practical choice for the slurry task, as their intricate course pathways can wear away or become stuffed expeditiously.

Not every valve gets built for each application, but a few industrial valves are prime at enduring the most harmful situations. As a result, a traditional function valve might not work nicely in strenuous, eroding, or extreme applications. Finding the best slurry valves for perplexing approaches might be a sluggish and expensive practice.

In order to prevent slurry passage, it is necessary to choose the valves created with the motive that does not need to be displaced and drop production. Whether acidic in a chemic facility, or grindings in oil sands, the slurry might give the tools a thrashing.

What Are Slurry Valves?

A valve is a machine-like tool utilized in liquid systems to manage, direct, separate, combine, or restrain the path or force of liquid by adjusting the pathway with the tube. Slurries might be a resilient liquid to pass. They could be grinding, eroding, and include a large proportion of solids. Slurries can get found in paper factories, sewage systems, and frac and quarry.

If a nozzle is in a vacant situation, the pathway gets cleared, and the liquid floats in a path from more increased force to reduce force. By blocking the route in the nozzle moderately or completely, its passage can get lowered or entirely ceased. Valves are usually the most expensive elements of a piping network in a factory, as their price might be approximately 30 percent of the general pipeline expense.

If bought from a reputable slurry valves manufacturer, valves for sludges deliver first-rate, are ahead of industry norms, provide effortless managing on media passage, and the complete drill design confines drainage to nearly none. The best valves for slurry applications contain superior opposition to deterioration and erosion, which explains why industry professionals favor them in corresponding applications.

Type Of Valves For Slurry Service Based On Their Design

Valves are machine-like and electro-impulsive instruments utilized for controlling the direction of fluids, powders, gases, and so on, along tubes or pipelines or from vessels or other receptacles. Hydrants depend on some mechanical barricade; a plating, a hop, or a capillary that can get positioned and terminated from the passage course of the material moving by.

Some slurry valve types are created as intermittent mixtures, although others permit very exceptional command of the progression of media. Selecting the correct valve type for the specific application is crucial.

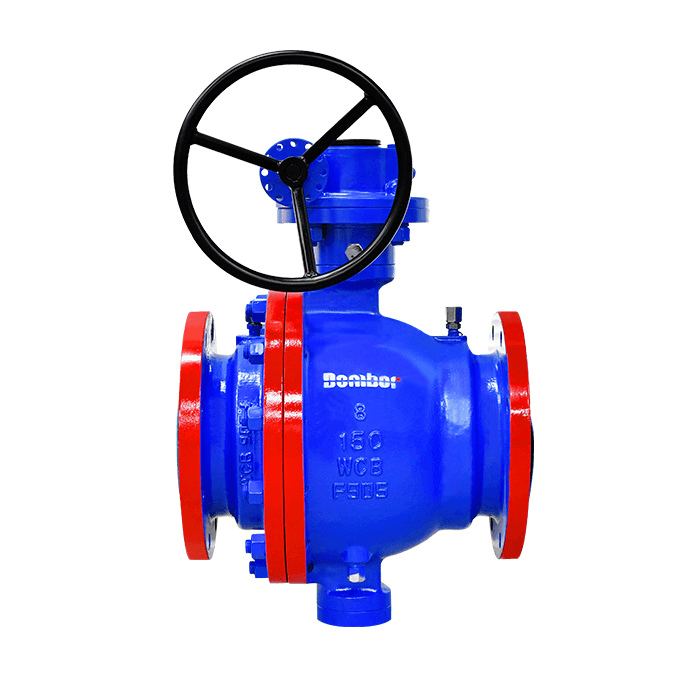

Slurry Ball Valve

An industrial ball valve manufacturerfabricates the valve that utilizes an empty ball to prevent or permit liquid discharge. The penetrated ball may get rotated operating the valve grip. If the borehole in the ball encounters the discharge channel, the liquid floats across. A quadrant-turn roundabout movement of the nozzle grip shifts the hop by 90° intercepting the discharge.

The slurry ball valve is shorter, more lightweight, and more affordable when approximated to door hydrants of the exact dimensions and grade. They permit optical observation of the unlocked or locked condition of a nozzle. In unlocked circumstances, the grip gets lined up with the indication of course, whereas in a locked situation, the grip is at right angles to the discharge path.

Furthermore, a ball valve for slurry application delivers the comfort of the process, large quantity discharge, increased power, extended assistance life, and the chance of restoration of seals and seats without extracting the hydrant body from the tube. Contrary to this, sludge ball valves are challenging to scrub, which may advance to defile. They are by no means appropriate for applications that need constant strangulation.

Butterfly Valve

The butterfly valves are quadrant-turn nozzles employing center-attached disc-shaped flaps that flutter from side to side of the discharge watercourse. Essential descriptions contain passage contact, valve dimensions, the materials that compose the nozzle body, its disc, seal, seat, and branch contents.

A high performance butterfly valve gets utilized in sewage systems, control stations, and manufacturing facilities for deactivation and for controlling and separating assistance and is particularly prevalent in eminently immense-module pipe routes.

Typically shorter and more reasonable than a slurry ball nozzle of the exact capability, a butterfly valve for slurry application can be complicated to work as opposed to high-power and discharge. They are even more leak-exposed than ball hydrants and dependent on more elevated head failures.

Pinch Valve

Pinch valves utilize flexible piping and a tweaking instrument that instantly limits the discharge via the piping. The tweaking system straightens the piping to form a lock. The pinch nozzles can get accustomed to starting, stopping, and regulating liquid discharge. As these nozzles include rarer elements, they are moderately more inexpensive and nonporous as contrasted to alternative valves.

These pinch valves for slurry are perfect for the atmospheric signifying of factual materials and for managing the biosolids. Pinch nozzles reduce disturbance and abrasion throughout discharge. Yet, they are hardly appropriate for gases, intense heat, or high-powered applications. A high-powered-distinctive or void in the mechanism might force the piping to crumple or wrench consequential in an unsaleable venting of the nozzle.

Gate nozzles are the utmost typical kind of hydrant encountered in factories. The ending gate pushes across a continuous route to intercept or permit liquid outpour. The slurry gate valvedelivers reasonable cessation and is considered appropriate for nearly all liquid assistances along with energy gas, air, slurries, feedwater, steam, and adhesive fluids.

Gate valves are affordable and uncomplicated to dismantle for supervision. They deliver lower liquid defiance because of a straightforward route that permits the liquid to pour directly over without a shift in regulation.

While utilized, the sludge gate valve is usually retained in a perfectly unlocked or thoroughly sealed condition as they do not get suggested for strangling applications. The valve structure causes it challenging to manage the outpour.

Likewise, the liquid striking against a partly loose gate may impair the nozzle. The various-rotate structure of such nozzles causes them to be inconvenient for applications where a quick approach is required.

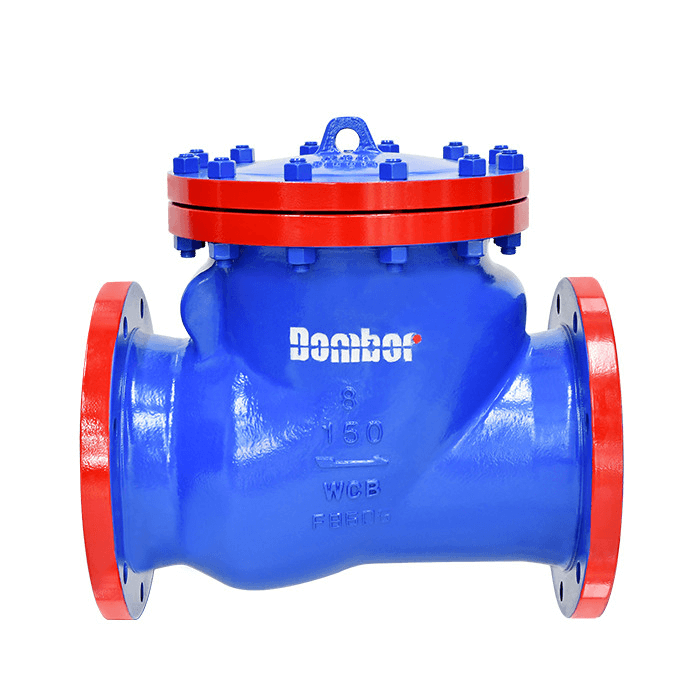

Slurry Check Valve

A check valve gets employed to control deterioration in tubing approaches. The nozzle unlocks consequently to the force of the liquid flowing through the tube. The opposite discharge seals the nozzle and stops the fluid from going on the contrary path. Check hydrants do not need outer supervision.

They operate spontaneously and therefore go without an operational grip or stem. The elementary check valves get organized with solitary flutter mechanics.

Check nozzles are typically short, easy, and reasonable.

The commercial applicability of the slurry check valve contains spread water management procedures, gas approaches that combine numerous gases into a sole gas streamlet, and energy and oxidize integrating techniques. In a private applicatory, a slurry ball check valve is utilized to control the unhygienic water systems from getting merged into hygienic drinkable water reserves.

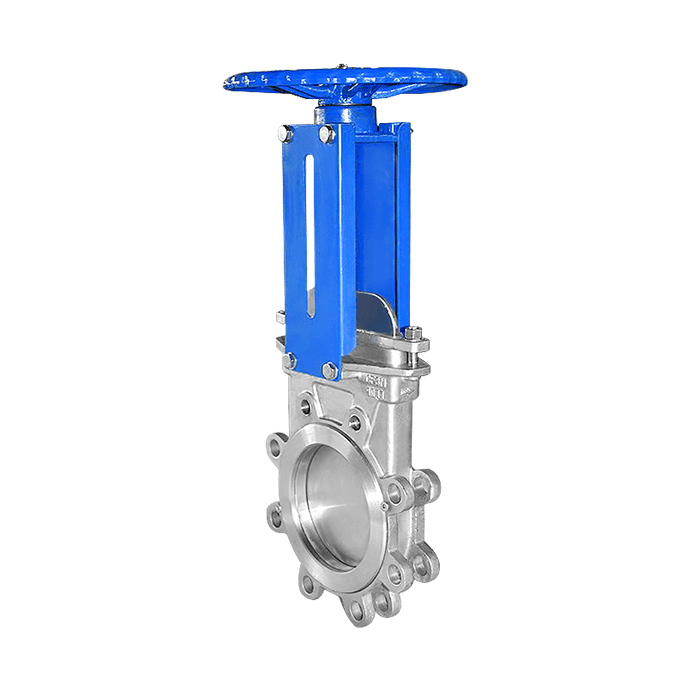

Slurry Knife Gate Valve

A bifacial knife gate nozzle is appropriate for utilization as completion. The valve body is the sole integral element, chromium steel through-channel gate, and two stretching sheaths. The prime attribute of slurry knife gate valves is it contributes a completely constant passage. It indicates that in an unlocked situation, it creates no holes, thereby, no conflict in the liquid.

The flow safety hood is self-sufficient on the control, ensuring that this signifies the hood can get dismantled, having no need to free the handle. This benefit permits routine supervision functions to get implemented, like greasing the stem.

This slurry knife gate valve is appropriate for performing in the drilling industry, in filled liquid transportation pipes like water with rocks, slurry, and so on, and generally for corrosive liquids in synthetic industrialization and sewerage. This nozzle stem gets created from chromium steel.

Slurry Control Valve

The slurry control valve exceeds in corroding applications during the global drilling segment that is nickel, diamond, copper, iron, potash, gold, or alternative procedure where valve implementation and expectation of life are integral.

In contrast with the standard line of area cavitation control valve like butterfly valves, pinch valves, and ball valves, the slurry flow control valve gives a quantity jump in serviceable life and decreases the general price of proprietorship for the utmost challenging operations.

Materials Used In Making Slurry Valves

Bearing the reality that sludges are generally highly corroding and grinding, the proper substances for valves must get specified. The adhering or corroding slurry may advance to escalating or distillation with the possibility of blocking productivity and damaging tools.

Causticity must get taken into consideration, not just for choosing the right seat or sleeve substance but even when deciding on the appropriate material for the hydrant’s body, gate, or housing.

The nozzle substances need to get adaptable to the gases or fluids pouring through them. The seats and gates need to get built of substances that can resist the operation requirements. For instance, genuine rubber is adequate for seat substance if sludges are corrosive. Plastic nozzles generally withstand intense or abrasive synthetics surpassing metal nozzles.

It gets generally suggested that the elements get covered with a forbidding substance, like stellite. Stellite gets built of chromium and cobalt alloys. This substance has high wear-resilient resources.

Components Of Slurry Valves

In contemplation of most adequately performing with nozzles, it is crucial to understand the uttermost essential components of hydrants. Valves are fabricated goods that comprise seven prime factors. Learn below about the various features and what every element accomplishes.

The Valve Body

The nozzle body not just accommodates other nozzle features, comprising the seat and disk, but it even is the prime pressure-reserve segment of the hydrant. It is also where liquid flows over the nozzle as both sides of the nozzle body get associated with tubing.

The sides may either be interspersed, bordered or concluded with spot welding kinds that rely on the dimensions and force of the tubing structure. The valve shells come in casting or shaped in a diversity of substances comprising chromium steel, alloyed steel, and casting steel determined on the necessities of the nozzle altogether.

The Bonnet

The bonnet is the second force-reserving element of a nozzle and gets even indicated as the guard. It is attached to the nozzle shell to make the hydrant compartment. In that instance, the diaphragm, globe, gate, or stop check nozzle holds an entryway where the nozzle stems to cross over and delivers entrance to the interior features of the nozzle during the required supervision.

The Stem

The nozzle stem’s objective is to share the necessary movement to the plug, ball, or disc conducive to opening and closing the nozzle. It gets attached to the hydrant lever, actuator, or handle on one side and the nozzle disc on the identical side.

In a globe or gate hydrant, the stem operates the straight movement of a disc for opening or closing the nozzle, although, in a ball, butterfly, and plug valves, the disc gets turned to unlock and shut it.

The Disc

The disc is the component of a hydrant that permits and ceases the discharge, determined by where it gets located. A nozzle disk may be fabricated, cast, or manufactured.

The Seat

The seat is the major component of the nozzle that promptly influences the speed at which the nozzle discharges and is an essential element of the nozzle shell. Hydrants may contain more than one seat regulated by the kind of nozzle. For illustration, a gate nozzle encloses two seats. One is on the flow of a stream edge and the further on the subsequent edge.

The Trim

Nozzle trim is a cumulative term for an adjustable or interchangeable interior component that advances into connection with the passage medium. These features contain the nozzle disc, seat, spacers, glands, bushings, guides, and inner springs.

The Actuator

The actuator in valves is the system that employs the valve and gets attached to the disk and stem meet. It may be hand-operated with a handle, gear, chain, or lever along with the turbine, alternator, hydraulic, or pneumatic system.

Factors To Consider When Selecting Slurry Valves

Slurries can be the utmost formidable liquid to drain. They are viscous, loaded with concretes, and often really corrosive.

Sealing is also usual with sludge applications. Nozzle configurations that deliver sites for sludge to pass off and harden are definitely never suggested. The corrosive concrete in sludges also scratches on tools in the structure, deteriorating the interiors and stopping nozzles from maintaining their close locks.

Check out these eight features experts suggest looking for when choosing a sludge nozzle.

Nozzle Type And Size

The first and foremost thing to focus on is choosing the correct nozzle type for the system. Each nozzle requires to conduct a fundamental role.

For illustration, informal sludges with lower degrees need pinch nozzles. Hydrants become more specific for sludges with elevated force and degrees. Most common nozzle configurations might never be adequate with most sludges, mainly corrosive ones, which can force substantial damage on tools.

Once the nozzle type needed in accord with the operation demanded is determined, ensure to adequately size the nozzle approximating the dimensions to the standard outpour through the design.

Enduring And Interchangeable Nozzle Seats

Seats have two roles, one is to shield metal elements inside the nozzle, and the other is to maintain a close lock to control leakage. Think about genuine rubber for seat substance, as this manages to bear the most satisfaction against corrosive sludges.

Likewise, look for nozzles with changeable seats. In corrosive applications such as sludges, being capable of swiftly changing out a seat is crucial for reducing interruption and operational charges.

Full Tubeline Doorway

Reduce the nozzle’s direction to the sludges along with a complete tube line beginning or complete port.

Useful Switch-Off

Sludges like synthetics and fertilizers are dangerous to the atmosphere and staffers. Consequently, it is crucial that the sludge nozzle specified has practical turn-off features.

Optimistic switch-off signifies that the nozzle has a stem that pushes the disc opposite to the seat.

Dissimilar to a diaphragm nozzle which can drain in case there is some failure in barometric force or dissolve if, in flames, an optimistic turn-off nozzle needs the bodily switching of the stem to unlock or shut.

Particular Necessities

Specific nozzles, like check valves, have exceptional necessities. Ensure that the selected nozzle functions as desired. Check out the feedback time needed and the crumbling force to unlock the nozzle.

An additional concern is the nozzle’s doorway. Some valves for slurry service, generally known as typically sealed check valves, demand optimistic downstream force to unlock. Other nozzles, usually named generally loose check valves, need optimistic backpressure to shut.

The quality consciousness of the check nozzle might get enhanced by pushing the suitable selection. The decision should get based on if the nozzle is unlocked and locked better throughout the standard system function.

High Force And Temperature Grade

Understand the aspects of the sludge prior to specifying the nozzle. Some sludges need heat and increased force to transfer them far away. The temperature and pressure of the sludge may command which substance and thermoplastics must get utilized in the function.

For illustration, slurry pressure relief valve made with metal favor withstanding more elevated forces and temperatures than plastic nozzles. Metal nozzles are also generally prime for intimidating gases. It is because they are inclined to be more substantial than plastic nozzles.

Self Debilitating

Sometimes, sludges require to get drained from the application. The self-debilitating quality benefits decrease supervision downtime and are possibly a machinist’s favored quality.

The Maintenance

It is necessary to evaluate constant supervision when selecting a nozzle, as it is crucial for the dependability and strength of the system. For instance, a side entry ball valve may withstand blocking, stuffing, and crashing but are inappropriate for modifying passage. Utilizing ball nozzles to maintain flow may permit valves to drain or break down hastily.

The nozzle reference type may even direct to improved supervision or renewal expenses. Every conjunction type incorporated, hooked, force-in, and so on holds its benefits and drawbacks, so ensure to do the analysis.

Contact Professional Slurry Valves Suppliers – Dombor

DomBor is the best industrial valve supplier with having expert team, providing a broad spectrum of valves that can fulfill precise industry needs. They deliver the finest assistance, whether for valve customization and order processing or quick delivery and proficient client service.

DomBor has earned multiple certificates regarding quality products and customer services with each passing year. All the industrial valves for slurry here get built adhering to ANSI/API, JIS, DIN, GOST, BS, and GB industry standards. They are qualified for handling extreme working situations and are excellent for industrial applications.

Performing closely with professional slurry valves suppliers can definitely assist in decreasing the expense of proprietorship and interruptions. To boost the expenditure, get in touch with a nozzle engineer familiar with the proper applications.

Bottom Line

For slurry applications, it is highly significant that a skilled team of professionals gets determined to acquire the best guidance based on the features of the slurries to reach a solution for reasons that cause untimely valve collapse. Investing a short time while purchasing the proper valve for slurry applications might result in considerable savings eventually in the future.

Valves manufacturer DomBor assembles an almost unbreakable flow control valve you can depend on easily. Get in touch with us to know how the products or customized valves can give you strong and enduring service at a reasonable price.

FAQs

Why valve is so important for slurry application?

While going for a nozzle preference, it is vital to not just peek at the operational requirements but even contemplate the prevalent surroundings.

The key reason why a slurry flow valve is the perfect option for maintaining the flow of sludges overlooking a vast industrialized zone is that they get implanted with an adjustable pipe that delivers a 100 percent watertight seal when it gets lifted or closed off.