Introduction to Ball Valve Dimensions: Why They Matter

In terms of efficiency and dependability of fluid control systems, understanding the dimensions of ball valves is important. Here, the dimensions of a ball valve influence not only its installation but also how it will perform and last in future. The right sizes ensure that flow rate is optimum as well as pressure drop is minimized, which minimizes chances of leaks happening. Whether you are dealing with full port or reduced port valves, it pays to know these various dimensions and also why proper tooling is crucial, since it can save you on time, cost implications involved and operational headaches.

These dimensions include but are not limited to ball valve size, bore diameter, and end connections. These different ball valve sizes must meet the requirements of the system for smooth operation and durability. For example, a Full Port Ball Valve (also referred to as Full Bore Ball Valve) provides maximum flow with minimum resistance; therefore best suited for high flow rate applications. On the other hand, reduced port valves are used where space constraints exist resulting in compactness without significant loss in performance. Knowing the ID of a ball valve is essential when finding out its flow capacity and if it fits with your system or not, making it important to understand the ease of use of different ball valve dimensions.

Key Elements Influencing Ball Valve Dimensions

There are a few things that must be taken into account while sizing ball valves. Each of these has a significant role in determining if the valve is fit for its intended purpose. Here is a detailed explanation divided into key points:

Pipe Size and Flow Coefficient:

- Consideration should be made to pipe size and desired flow coefficient. For larger pipes, it may require that the valves have to have increased bore diameters so as to allow for higher flows compared to smaller systems where standard port valves can be used to regulate the flow.

Type of End Connections:

- The type of end connections such as threaded ball valves or camlock fittings also determine their dimensions. Smaller valves commonly utilize threaded connections which make them easier to install and repair compared with discharge couplings that are used in situations requiring disconnection and reconnection frequently.

Valve Body Material:

- In addition, the overall dimensions will depend on whether it is considered as stainless steel ball valve or brass ball valve because different material properties mean that varying strengths are needed.

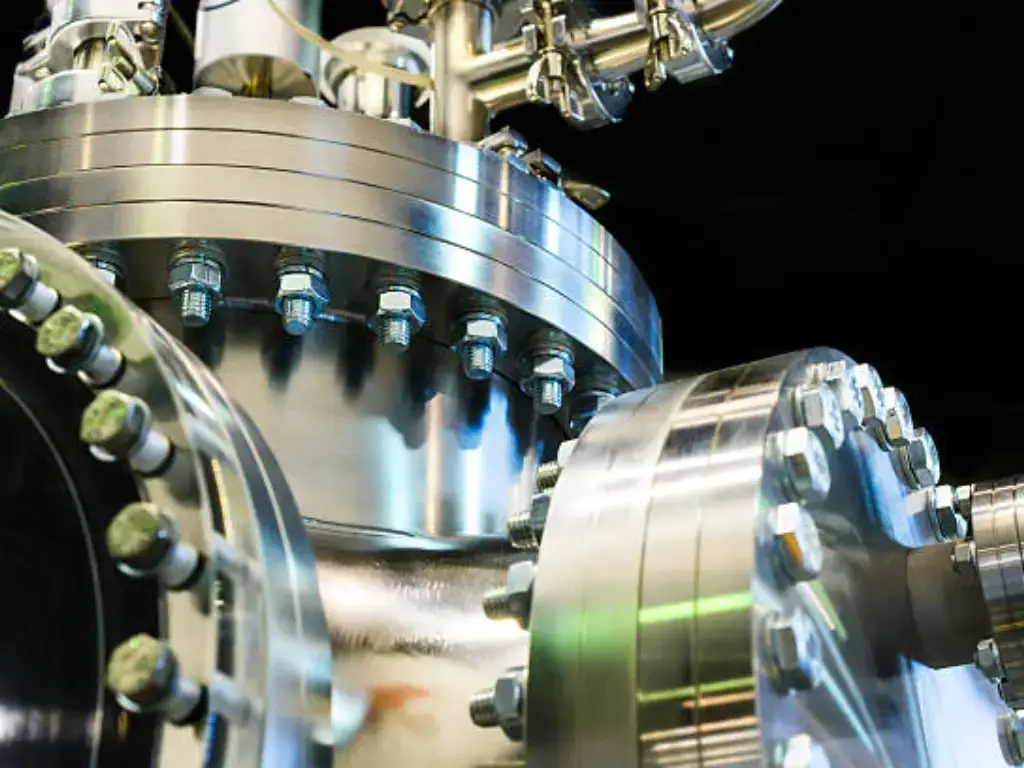

Pressure Rating:

- Another factor to consider is the system’s pressure rating (measured in psi). High-pressure applications need tough bodies joined by heavy duty end connectors, i.e., reinforced body joints; all-welded structure with no bolt holes and durable wetted parts.

Design Standard:

- Design standards such as ASME or API ensure compliance of these devices with industry norms governing safety and performance.

To conclude, knowledge about these factors is very important when selecting an appropriate ball valve for specific applications since this guarantees efficiency and operational safety in any given system design.

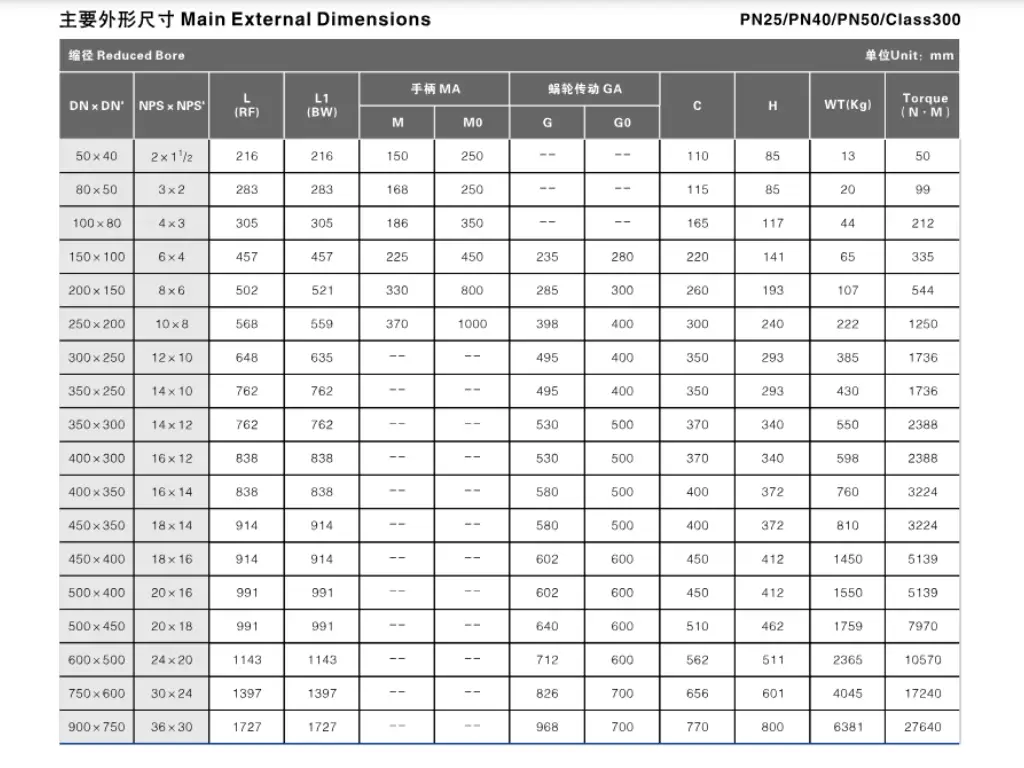

Full Bore vs. Reduced Bore Ball Valve Dimensions

The main thing one looks for in a ball valve is whether to go for full or reduced bore valve. Full bore ball valves, sometimes called as full port ball valves have a ball which has a hole diameter equal to the nominal diameter of the pipe. This design ensures that there is minimal pressure drop and a full flow rate can be reached hence fit for areas that demand high flow efficiency and low cost. However, for those looking for a more cost-effective option, a reduced bore ball valve, also known as a standard port ball valve, may be suitable. These one piece ball valves are durable and reliable, with no joints for potential leaks. It is important to consider the suitable mediums for each type of valve, with full bore valves being suitable for water, oil, and gas products, while reduced bore valves may have limitations in their compatibility. Additionally, full bore valves have the advantage of a larger ball, which allows for a full bore or full port design, meaning that the bore hole in the ball has the same inside diameter as that of the piping it is connected to. For OEM’s, the 2 Piece SS Ball Valve is a good option as it is relatively inert and can withstand contact with mild chemicals and acids, making it a versatile and durable choice.

On the other hand, in reduced bore ball valves, the bore diameter is smaller compared to the nominal diameter of the pipe. This causes little restriction of flow which may be helpful where controlling the flow takes precedent over high flow rate. Nonetheless, if not properly sized, reduced bores can increase pressure drops and possibly even lead to cavitation problems.. It’s important that you understand what your system really needs between full and reduced bore when it comes to selection for best results.

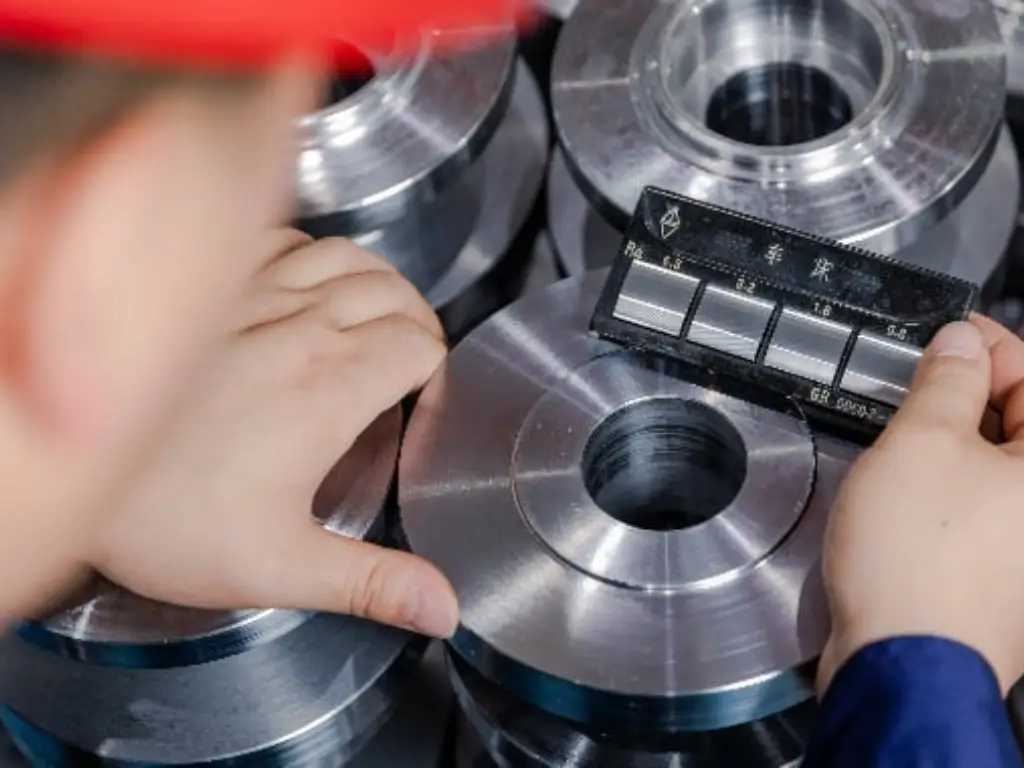

How to Accurately Measure Ball Valve Dimensions

Accurately measuring ball valve dimensions involves several steps to ensure compatibility with the system. Begin by determining the nominal diameter, which corresponds to the ball valve size and the size of the hose or pipe. This measurement is crucial for ensuring that the valve fits properly within the piping system, maintaining a secure and leak-free connection.

Next, measure the bore diameter to understand the internal flow capacity of the valve. For full bore ball valves, this dimension should match the nominal pipe size to allow unrestricted flow. Reduced port valves will have a smaller bore, which must be considered when calculating the flow coefficient and pressure drop.

The end connections, whether threaded, flanged, or camlock, also need precise measurement to ensure they match the piping configuration. It’s essential to refer to a ball valve size chart for standard dimensions and general dimensions that comply with industry standards. Additionally, consider the overall length and height of the valve, including the PSI rating, to ensure it is compatible with the system’s pressure needs.

Common Ball Valve Dimensions :You Should Know

To suitably select and install them, you need to understand the ball valve dimensions. Commonly, ball valves are manufactured in standard sizes that match with most pipe systems out there. Here are the main dimensions that you should consider:

Valve Size (DN or NPS):

- From 1/4 inch (DN8) through to 12 inches (DN300), is what usually composes the various sizes.

Port Size:

- Full port valves have a bore equal to pipe size, ensuring no flow restriction. Reduced port valves will have a smaller bore reducing flow.

End-to-End Length:

- Typically, an ANSI standard 1-inch valve measures about 108mm while a 4-inch valve measures around 229mm.

Flange Diameter:

- Out of all flanged valves, for a 2-inch valve it is approximately 150mm and for a 6-inch valve it is nearly 280mm.

Stem Height:

- For mounting actuators, shorter ones start from about 50mm up to over 200mm for larger ones.

Pressure Rating:

- PSI or bar with common ratings being; five hundred and fifty; hundreds fifty as well as three hours zero p.s.i.

Choosing the right ball valve is very important because it involves understanding the ball valve dimensions.These dimensions ensure compatibility and optimal performance in various applications.

Impact of Incorrect Ball Valve Dimensions on System Performance

It is important to note that any wrong dimensions of a ball valve may have serious effects on the system performance. On the one hand, when a valve is too small for pipe size, there could be a significant pressure drop thereby decreasing system effectiveness and probably leading to cavitation. Conversely, if it is too huge in relation to the size of the pipes, it may prove difficult to fit and not provide enough control over flow.

Incorrect sizes can also cause leaks at body joint or end connections which will result in system downtime and increased maintenance costs. Having correctly sized ball valves is therefore important in maintaining system integrity and dependability as well as avoiding corrosion and other related issues. When selecting these devices, always consider industry standards such as ASME or API specifications.

Tips for Selecting the Right Ball Valve Dimensions for Your Needs

Factors to consider before choosing the right ball valve dimensions are many. Start by examining your system needs, such as flow rate, pressure rating and pipe size. Use a sizing chart to compare dimensions for compatibility.

Also, the material of the valve body should be considered in relation to media and environmental conditions (like stainless steel or brass). SS valves are strong and resistant to chemicals; however brass is cost-effective when used for less demanding applications.

Lastly, take note of the end connections and design standards. Threaded valves can be good for small systems with low-pressure systems while flanged or camlock fittings for large high pressure ones.Capable of being connected securely through male NPT threads, Secure connections can also be made using Male NPT threads, which stands for National Pipe Thread. They come with Teflon (PTFE) seals and handle locking devices that need to be evaluated alongside these factors so as to choose the best ball valve dimensions that will guarantee system’s performance longevity.

Choose Dombor for High-Performance, Long-Lasting Ball Valves

When choosing a ball valve dimension that is right for your needs, you need to keep in mind that it should have long life and high performance. For reliable and high-quality ball valves you may consider Dombor which is China’s leading manufacturer since 2001. With an experience of more than 3000 projects especially in the oil and gas sector, Dombor makes available ball valves of different sizes, pressure ratings, and materials. The company manufactures their valves according to ANSI, API, BS, DIN, JIS, GB standards thereby ensuring compatibility and reliability. Dombor’s valves are highly successful at work environments with above industry average 70% product acceptance rate in high temperature or loaded with particulate matter. Put simply; select Dombor if you want excellent quality products certified by such global standards as API 6D and ISO 9001 with a guarantee period of twenty-four months as well as prompt delivery.