Have you ever wondered where the wastewater produced in your home and other establishments go? Well, you might say the drainage system moves it underneath the ground. Fine, but the soil is the major source of water, which means that the wastewater is mixed with the water that springs up.

According to the United Nations (UN), out of 89 countries with water quality data, only 52 have information about groundwater, which is bad because groundwater generates the largest share of freshwater in a country.

This is why it’s important that quality wastewater treatment equipment are utilized to purify the water. In lieu of that, we will be discussing salient topics about this concern, including the importance, sewage treatment equipment, the working process, industries that can apply this, and how to choose the right equipment.

Importance of Wastewater Treatment

Wastewater treatment is a crucial process that helps to purify wastewater generated from various sources such as homes, industries, and commercial establishments. The primary aim of wastewater treatment equipment is to remove contaminants from the water and make it safe for reuse or discharge back into the environment.

There are several reasons why wastewater treatment is of utmost importance:

- Public health and safety: Wastewater contains a wide range of harmful contaminants, including pathogens, toxic chemicals, and heavy metals, which can cause severe health problems if not treated properly. Hence, wastewater treatment is essential to protect public health and safety by removing these contaminants and reducing the risk of waterborne diseases, like cholera, dysentery, and hepatitis A.

- Protection of the environment: Treated wastewater is usually discharged back into the environment, and if not treated properly, it can pose a significant threat to the environment. Wastewater can pollute rivers, lakes, and other water bodies, killing fish and other aquatic life, and causing harm to plants and animals that depend on these water bodies for survival. The treatment helps to reduce the impact of wastewater on the environment by removing pollutants and ensuring that the water is safe for discharge.

- Water reuse: With increasing water scarcity, it has become increasingly important to conserve and reuse water. Treated wastewater can be a valuable source of water for various purposes, including irrigation, industrial processes, and even drinking, after proper treatment and disinfection.

- Economic benefits: Wastewater treatment can bring significant economic benefits, including job creation, reduction in the cost of fresh water, and reduced environmental degradation. Additionally, industries that discharge large quantities of wastewater can save money by properly treating their wastewater and avoiding penalties for environmental violations.

- Compliance with regulations: Wastewater treatment is regulated by local, state, and federal laws, which require that all wastewater be treated to specific standards before it can be discharged into the environment. Failure to comply with these regulations can result in penalties, fines, and legal action, as well as damage to the organization’s reputation.

Proper wastewater treatment is crucial for a sustainable future, and it is essential that all individuals, industries, and organizations work together to ensure that wastewater is treated properly and responsibly.

Influence of Industrial Wastewater Treatment beyond Compliance

The objective of treating industrial wastewater is to remove harmful pollutants and reduce the risk of contaminating surface and groundwater sources. Also, wastewater treatment companies are saddled with the responsibility of complying with tight federal regulations, such as the Clean Water act, the Safe Drinking Water Act, and the Resource Conservation & Recovery Act. Asides these, there are some state and local level regulations that must also be adhered to.

What most companies do is to use water treatment plant equipment that comply with these industry regulations. However, the influence of industrial wastewater treatment systems should extend beyond compliance with environmental regulations. The benefits of proper wastewater treatment go far beyond meeting regulatory requirements and can have a significant impact on the economy, public health, and the environment.

Another influencing factor to industrial wastewater treatment is the reduction of greenhouse gas emissions. Greenhouse gas emissions from wastewater treatment plants contribute to climate change, which can lead to increased temperatures, rising sea levels, and extreme weather events. By implementing effective wastewater treatment processes, companies can reduce their carbon footprint and help to combat climate change. This also helps to improve the overall working environment, boost workers morale, and adherence to ISO 14001 initiatives.

Also, the proper treatment of industrial wastewater helps to conserve water resources. The water treatment process helps to recover valuable resources such as nutrients, chemicals, and energy, which are recycled and reused, thus reducing the need for fresh water supplies. By conserving water resources, companies help to mitigate water scarcity and promote sustainability.

List of Industrial Wastewater Equipment and their Benefits

The following includes the major sewage treatment equipment, as well as their applications.

Industrial Valve

Industrial valves play a critical role in wastewater treatment systems as they control the flow and pressure of wastewater, allowing for efficient and effective treatment processes.

In the treatment process, valves are used to control the flow of wastewater to various treatment stages, including preliminary treatment, primary treatment, secondary treatment, and final disinfection. The valves help ensure that wastewater is properly mixed, aerated, and treated with chemicals to remove pollutants.

Wastewater treatment plants use a variety of valves, including gate valves, ball valves, butterfly valves, and diaphragm valves, to regulate the flow of wastewater through the treatment process. For example, gate valves are often used to control the flow of raw wastewater into the treatment plant, while industrial ball valves are used to regulate the flow of treated wastewater from the plant.

Industrial valves are also used in sludge treatment processes to regulate the flow of sludge to storage or treatment facilities. The valves help prevent the release of untreated or partially treated wastewater into the environment, protecting public health and the environment.

Ultrafiltration System

Ultrafiltration (UF) system is an industrial wastewater equipment that operates by using a semi-permeable membrane to remove impurities, suspended solids, and microorganisms. The water is pressurized and forced through the membrane, which allows only clean water to pass through while retaining contaminants.

UF system is manufactured to reduce oily water volumes by up to 98% without using chemical additives. The system can also remove small fines in deburring and tumbling operations, allowing the water and soap solution to be recycled and reused.

The application of this equipment is also cost-effective and it’s quickly becoming the most sought-after filtration equipment. It’s often used in the food and beverage, pharmaceutical, cosmetic, and detergent industries.

Vacuum Evaporation and Distillation

Vacuum evaporation and distillation are industrial wastewater treatment processes that use heat to separate water from contaminants. Evaporation is a natural process and a clean water treatment technology recognized as the best process across many industries. This is because it naturally removes the water from the contaminants, instead of going through a filtration process. In distillation, the water is heated and vaporized, and then condensed back into a clean liquid.

These processes are often used in the chemical, petrochemical, and pharmaceutical industries. And they are preferred for their high separation efficiency, high water-recovery, low water waste, and low energy consumption.

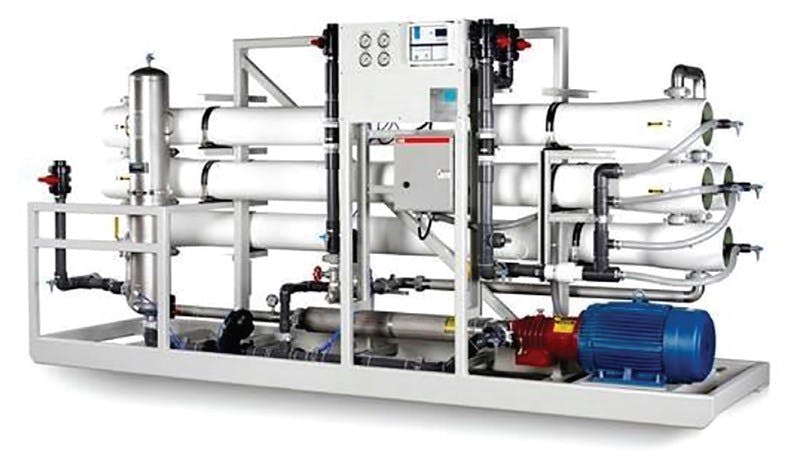

Reverse Osmosis System

Reverse osmosis system is an industrial wastewater equipment that operates by using a semi-permeable membrane to remove impurities and contaminants from water. The water is pressurized and forced through the membrane, which allows only clean water to pass through while retaining contaminants.

The membrane requires that a greater-than-osmotic pressure and high pressure water is used to get the desired result. The water that flows through the reverse osmosis is called the “permeate” and the contaminants that are retained are called the “concentrate.” A properly manufactured and operated reverse osmosis system can remove up to 99.5% contaminants from the most challenging waste and feedwater applications.

The reverse osmosis system offers high removal efficiency, low energy consumption, and low maintenance. This equipment is often used in the metalworking, food and beverage, pharmaceutical, and cosmetic industries.

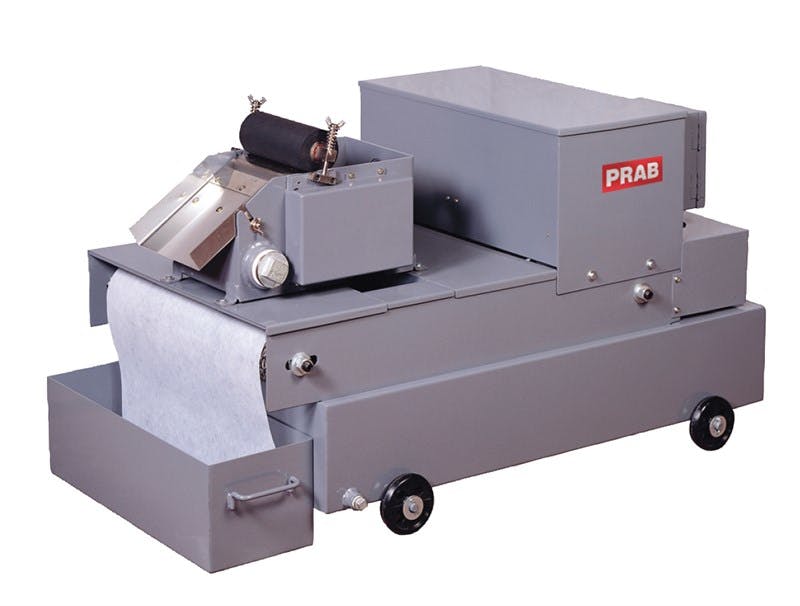

Paper Bed Filter

Paper bed filter is one of the industrial wastewater equipment systems, but it operates by filtering wastewater through layers of paper. This type of filter functions using gravity and disposable paper media to produce a positive barrier that stops any form of solid in the flowing liquid. The water passes through the paper, removing impurities and suspended solids.

This equipment is used for applications that require low to medium stock removal of ferrous and non-ferrous metals, as well as organic and inorganic impurities, like plastic, rubber, and glass. A properly designed and operated paper bed filter offers low energy consumption, low maintenance, and high removal efficiency, and can extend the coolant and tool life by an average of 27%.

Solid Bowl Centrifuge

Solid bowl centrifuge is a wastewater treatment equipment that operates by using centrifugal force to separate solids from liquid. The liquid is fed into the centrifuge, which spins at high speed, causing the solids to settle at the bottom while the clean liquid is expelled.

While the process liquid is either pumped or gravity-fed into the centrifuge inlet, the process solid is centrifugally separated from the liquid and extracted in an easily removable rotor, which is also known as a “liner.” Then, the purified liquid overflows the liner into the outer case and returns with gravity to the process, minimizing the cost of hauling waste coolants and water away from the factory.

This equipment is often used in metal, chemical, petrochemical, and pharmaceutical industries. It offers many benefits, including high separation efficiency, low energy consumption, and low maintenance.

Tramp Oil Separator

The tramp oil separator is an industrial wastewater equipment that operates by removing tramp oil from wastewater. The wastewater is fed into the separator, which uses a combination of gravity, skimming, and coalescing to separate the tramp oil from the water.

In this treatment solution, wastewater flows through a series of baffles and a porous media bed. During this process, free and mechanically dispersed oils are filtered from the liquid, then the purified liquid flows over the effluent discharge weir back to the reservoir for reuse. The oils and other waste products are gathered at the top of the separator and automatically discharged into a suitable receptacle.

This tramp oil separator is often used in the metalworking and machining industries. Asides its basic functions, it reduces new liquid purchase costs up to 75%, reduces the cost of wash water detergents, heating & disposal, as well as a 90% reduction in the hazardous waste volume.

Vacuum Filter

Performing a similar function as an industrial basket strainer, the vacuum filter is an industrial wastewater equipment that operates by using a filter cloth and vacuum pressure to remove impurities and suspended solids from wastewater. The process involves passing wastewater through a filter medium, such as a drum or a belt, that captures and removes the solid particles. The filtered water is then collected and discharged, while the captured solids are compacted and removed for further processing or disposal.

There are several types of vacuum filters used in wastewater treatment, including drum filters, belt filters, and disc filters. The basic principle behind all of these filters is the same, but the specific design and operation may vary.

Drum filters use a rotating drum to capture solids from the wastewater. The drum is covered with a filter medium, such as a mesh or a cloth, which removes the solids as the wastewater passes through. The solids are collected on the outside of the drum and removed for disposal.

Belt filters use a continuous belt to remove solids from the wastewater. The belt is covered with a filter medium and passes over a series of rollers. As the wastewater is applied to the top of the belt, solids are captured and removed. The filtered water is collected on the bottom of the belt, while the solids are removed for disposal.

Disc filters use a series of disc-shaped plates that are stacked together to form a filter. The wastewater is passed through the discs, and solids are captured on the surface of the discs. The filtered water is collected on the other side, while the solids are removed for disposal.

Working Process of Wastewater Treatments

Industrial wastewater treatment is a process that involves several stages to remove pollutants and make the water safe for discharge into the environment or for reuse. The following is a brief overview of the process:

- Pretreatment: The first stage involves removing large solids, oils, and grease from the wastewater using screens, skimmers, and sedimentation tanks.

- pH adjustment: The pH of the wastewater is adjusted to a neutral range to improve the efficiency of the subsequent treatment processes.

- Primary treatment: The wastewater is subjected to physical treatment such as sedimentation to remove suspended solids and oil droplets.

- Biological treatment: The wastewater is treated biologically to remove organic pollutants. This is done by introducing microorganisms that feed on the organic matter and convert it into less harmful substances.

- Secondary treatment: Secondary treatment further removes dissolved and suspended pollutants. This is usually done through a combination of processes such as activated sludge treatment, aeration, and sedimentation.

- Tertiary treatment: Tertiary treatment involves removing any remaining pollutants such as nutrients, heavy metals, and pathogens. This is done through processes such as filtration, ion exchange, and disinfection.

- Sludge treatment: The final stage involves treating the solid waste produced during the treatment process. The sludge is stabilized and disposed of in an environmentally responsible manner.

The choice of treatment processes and the extent of treatment depend on the nature and composition of the wastewater, the regulations in the region, and the desired end use of the treated water. The aim of industrial wastewater treatment systems is to reduce the pollutants in the wastewater to levels that are safe for the environment and meet the regulatory requirements.

What Industries Can Wastewater Equipment Used for

Wastewater treatment is an essential process in several industries for purifying contaminated water and making it safe for reuse or discharge into the environment. Here are some of the industries that utilize wastewater treatment:

Municipal

Municipal wastewater treatment plants are responsible for treating sewage from households and businesses in urban areas. The purpose of this treatment is to reduce the contaminants in the water to levels that are safe for discharge into nearby bodies of water.

Food and Beverage

The food and beverage industry generates significant amounts of wastewater that contains organic matter, oils, and chemicals. Wastewater treatment in this industry helps to reduce the levels of these contaminants, making the water safe for discharge or reuse in other processes.

Pharmaceutical

Pharmaceutical manufacturing generates wastewater that contains a range of chemicals and active pharmaceutical ingredients. Treatment of this wastewater is crucial to reduce the levels of these contaminants and make the water safe for discharge.

Petroleum

The petroleum industry generates significant amounts of wastewater, including produced water from oil wells and wash water from equipment cleaning. Treatment of this wastewater is necessary to reduce the levels of oil, chemicals, and other contaminants, making the water safe for discharge.

Pulp and Paper

The pulp and paper industry generates wastewater that contains high levels of organic matter, chemicals, and suspended solids. Treatment of this wastewater helps to reduce the levels of contaminants and make the water safe for discharge or reuse in other processes.

Textile

The textile industry generates wastewater that contains dyes, chemicals, and other contaminants. Treatment of this wastewater is necessary to reduce the levels of these contaminants and make the water safe for discharge or reuse in other processes.

Metalworking

Wastewater treatment equipment is used in the metalworking industry to remove contaminants such as metal particles, oils, coolants, and cleaning agents from processed wastewater, so that the treated water can be reused or safely discharged to the environment.

How to Choose the Right Wastewater Treatment Equipment for Your Need

Choosing the right wastewater treatment equipment is crucial for managing and processing the waste generated by industrial, commercial and residential establishments. The right sewage treatment equipment will ensure that the waste is processed efficiently, safely and in compliance with environmental regulations. Here are some key factors to consider when selecting wastewater treatment equipment.

- Type of Waste: Different types of waste require different treatment processes. For example, industrial waste may contain chemicals and hazardous materials, while residential waste is mainly composed of organic matter. It is important to determine the composition of the waste so that the appropriate treatment process can be selected.

- Volume of Waste: The volume of waste generated will determine the size and capacity of the equipment required. A large volume of waste will require a larger capacity system, while a smaller volume can be treated with a smaller system. It is important to consider the future growth and expansion plans of your establishment when choosing equipment.

- Treatment Goals: Different treatment goals will require different processes and equipment. For example, if the goal is to remove impurities, then a filtration system may be required. If the goal is to reduce the volume of waste, then a compression or drying system may be necessary. It is important to clearly define the treatment goals to select the right equipment.

- Compliance with Regulations: Wastewater treatment equipment must comply with environmental regulations and standards. This includes standards for discharge limits, waste handling, and safety. It is important to check with the local authorities to ensure that the equipment complies with all relevant regulations.

- Cost: The cost of the equipment and the operational costs must be considered when choosing the right equipment. The initial cost of the equipment will vary depending on the type and size of the system, while the operational costs will depend on the energy consumption, maintenance, and replacement parts. It is important to consider both the initial cost and the long-term operational costs when choosing equipment.

- Technology: The technology used in wastewater treatment equipment has advanced significantly in recent years, and it is important to consider the latest developments in technology when choosing equipment. For example, in the industry, the help of a professional butterfly valve manufacturer is employed for OEM valves. Also, newer systems may be more energy-efficient, require less maintenance, and have a smaller footprint compared to older systems.

- Service and Support: The availability of service and support is an important consideration when choosing wastewater treatment equipment. The equipment must be backed by a reliable service and support network to ensure that it operates smoothly and efficiently.

Conclusion

Choosing the right wastewater treatment equipment requires careful consideration of the type of waste, volume of waste, treatment goals, compliance with regulations, cost, technology, and service & support. A well-selected system will ensure that the waste is treated efficiently, safely, and in compliance with environmental regulations.

It is important to seek the advice of experts and specialists when choosing equipment to ensure that the right tool is selected for your specific needs. Dombor is a reliable industrial valve manufacturer with years of experience in producing high-quality wastewater treatment equipment that passes the industry-regulated compliance rate and achieves your desired result with great efficiency. You can contact us for all your industrial vales used for wastewater treatment systems.