Introduction to Ball Valves

Definition and Basic Function

Ah, the world of ball valves, a realm often unexplored by many yet so vital in our everyday lives. Picture this: a device, simple yet ingenious, designed to regulate the flow of substances through pipes. This is the essence of a ball valve. At its heart, a ball valve is a form of quarter-turn valve which uses a hollow, perforated, and pivoting ball (often made of robust materials like stainless steel or brass) to control flow. It’s fascinating, isn’t it? How this simple mechanism plays such a pivotal role in controlling the flow in our piping systems.

Importance in Industrial Applications

Now, let’s take a stroll down the industrial lane. Ball valves are not just bits of hardware; they are the sentinels guarding the efficient operation of numerous systems. From your home’s water system to the vast networks of pipelines in petrochemical plants, these valves ensure that everything runs smoothly and safely. It’s their reliability and simplicity that make them a favored choice in various applications. Can you imagine a world without these guardians? Chaos in flow control, I’d say!

Basic Components of Ball Valves

Diving into the anatomy of ball valves, we find that they are marvels of engineering simplicity. Essentially, industrial ball valves consist of four main parts: the valve body, the ball itself, the stem, and the seat. Each segment plays its unique role. The body holds everything together, while the ball, the celebrity of our story, sits majestically inside, ready to rotate and control the flow. Then comes the stem, the connection between the ball and the external control mechanism, and finally, the seat, which forms a tight seal ensuring no unwanted escape of the fluid or gas. For extensive knowledge on ball valve components, visit our related blog post for valuable information.

The Mechanics of Ball Valves

How Ball Valves Operate?

Imagine turning a lever or a knob, and inside, the ball rotates, its hole aligning or misaligning with the flow path. This motion either allows the flow or halts it, making it an efficient mechanism for quick shut-off. It’s this simplicity and effectiveness that make ball valves so reliable.

Ball Valve Actuation Methods

Ball valves come with different actuation options – manual, pneumatic, electric, and even hydraulic. The choice depends on the application’s needs. For instance, in a remote pipeline, an electrically actuated ball valve might be the star, responding to signals sent from far away, controlling the flow like a dutiful sentinel.

Types of Ball Valves Based on Bore Size

Full Port Ball Valves

Full port ball valves, also known as full bore ball valves, are the powerhouses. They have a bore diameter equal to the connected pipeline, ensuring minimal friction and pressure loss. They are like the open highways for fluid flow, allowing substances to pass through without much ado.

Standard Port Ball Valves

Next, we have the standard port ball valves. These are the more common types you’ll encounter. They have a smaller ball and a smaller port, leading to some pressure drop, but they are generally more robust and versatile.

Reduced Port Ball Valves

Reduced port ball valves, also known as reduced bore ball valves, offer an even smaller passage for flow. They are the wise choice when you need to control the flow meticulously, like a careful gardener tending to his plants.

Types of Ball Valves by Body Assembly

Single Body Ball Valves

Single body ball valves are the epitome of sturdiness. As the name suggests, they are made from a single piece of material, offering robustness and fewer leak paths.

Split Body Ball Valves

Split body ball valves, on the other hand, are like puzzles, made of two or more pieces bolted together. This design makes maintenance and disassembly easier, a blessing for those who regularly service their systems.

Top Entry Ball Valves

Top entry ball valves are the stars of convenience. They allow access to the internals of the valve through the top, making maintenance and repairs a breeze, especially in large, complex systems.

Welded Body Ball Valves

And then we have the welded body ball valves. These are the sentinels in high-integrity applications, where the body is welded shut, leaving no room for leaks or external contaminants.

Wanna know about ball valve price? Read our detailed guide or contact us directly for information.

Types of Ball Valves According to Port Configuration

Ball valves come in different types, based on what a job needs.

Two-Way Ball Valves

Let’s start with the two-way ball valves. These are simple – they have one way in and one way out, an inlet and an outlet. They’re great for just turning things on or off. Think of them like a light switch. If you get a two-way ball valve with a full port, it lets the flow go through easy, just like the pipe size, without squeezing it. This means less rubbing – or friction – and less push-back from the valve.

Three-Way Ball Valves

Then there are the three-way ball valves. These guys have an extra spot for the stuff to go. They’re good for moving flow this way or that, like a traffic cop directing cars. You can get them in an L or T configuration, so the flow can go straight or make a turn, depending on what you need.

Multi-Port Ball Valves

Now, multi-port ball valves, they’re the cool tools with more than two ways. They can do a bunch of things: stop, go, mix, or split the flow, all in one. It’s like having a handy multi-tool in your piping system. They make sure everything flows where it should, without needing extra valves to join the party.

Specialty Ball Valves for Diverse Applications

V-Port Ball Valves

V-Port ball valves are the specialists. Their V-shaped ball or seat is designed for better throttling control. They can handle the subtleties of flow regulation, much like a skilled artist can handle the nuances of their craft.

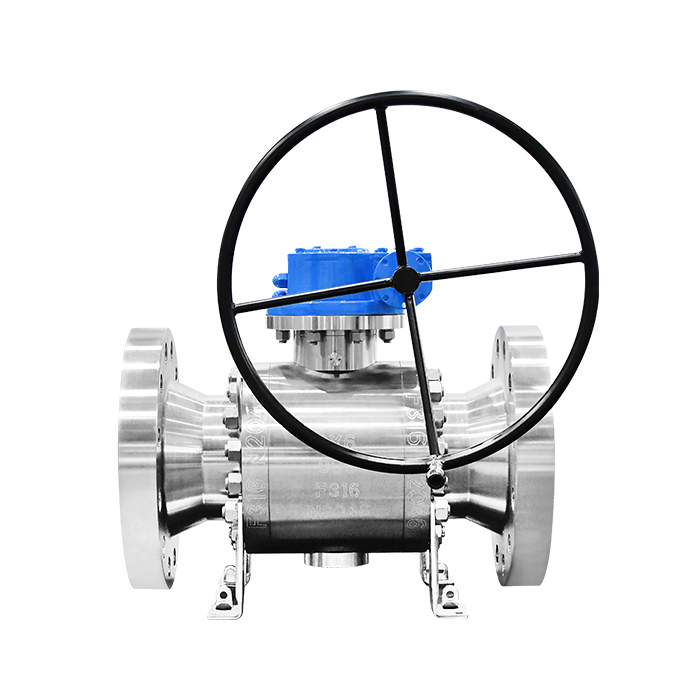

Trunnion Mounted Ball Valves

Trunnion ball valves are the heavy-duty performers. They are designed to be super strong. Supported by a trunnion, they are perfect for high pressure applications where the operating torque required to turn the trunnion valves could be substantial. This helps a lot because it means the valve seats don’t have to deal with so much pressure. Imagine diving really deep in the sea and feeling all that water pushing on you – that’s the kind of pressure these valves can handle.

Floating Ball Valves

Floating ball valves are the nimble dancers of the valve world. The ball is held in place by the compression of two elastomeric seats against it. They are adept at maintaining a tight seal and are typically used in low to medium pressure applications.

| Ball Valve Type | Features |

| Full Port | Big path for flow, like a highway. No squeezing, less pressure drop. |

| Standard Port | Common type, a bit of a squeeze on flow, good for many jobs. |

| Reduced Port | Smaller path, great for careful control, like fine-tuning. |

| Single Body | Strong, one-piece design, fewer places for leaks. |

| Split Body | Made of pieces, easy to take apart and fix. |

| Top Entry | Open from the top, easy to reach inside for fixes. |

| Welded Body | Sealed up tight, no leaks, good for safety. |

| Two-Way | Simple on/off job, like a light switch. |

| Three-Way | Directs flow in two spots, handy for choosing paths. |

| Multi-Port | The Swiss Army knife of valves, does lots of jobs in one. |

| V-Port | Fine control, like a paintbrush for flow. |

| Trunnion Mounted | For heavy-duty pressure, like a strongman. |

| Floating | Good for medium pressure, keeps a tight seal. |

Ball Valve Seat Materials and Their Impact

Teflon seats are like the silent guardians. They provide excellent chemical resistance and reduce the friction between the ball and the seats, ensuring a smooth operation and a tight seal. Metal seats, on the other hand, are the warriors, capable of withstanding high temperatures and abrasive conditions. They are generally more robust and can handle more aggressive applications.

Ball Valves in Throttling Service

When picking the type of valve for throttling, ball valves have their own pros and cons to consider. Let’s look closer.For the pros, some ball valves are made with a special ‘V-port’. This design helps the valve give better flow control, a bit like a tap that can finely adjust water flow. They work well when you need more than just on or off, handling varied flow needs in a system.However, there are cons too. Ball valves can be tricky for delicate adjustments. They’re not the best at tiny, precise changes – kind of like trying to use your phone with gloves on. Plus, if not chosen or used correctly, they can wear out quickly. This can lead to leaks or a need for more frequent replacements.It’s also worth noting that ball valves can be noisy and may cause cavitation, which is when bubbles form and burst, potentially damaging the valve. So, they are more like a good all-around player in a team, not the specialist you might need for complex, precision plays.

Material Selection for Ball Valves

Selecting materials for ball valves is critical in the design of ball valves, much like choosing the proper gear for a specific sport. The medium it regulates, pressure, temperature, and surrounding conditions dictate different material that is suitable.Take stainless steel; it’s robust and fights rust well. It’s perfect for dealing with aggressive fluids or high-pressure situations. Picture it in a factory setting where strength and endurance are key.Brass, on the other hand, offers a solid middle ground. It’s less expensive than stainless steel and still performs reliably under moderate temperature and pressure. It’s common in home plumbing systems – an everyday champion.Lastly, PVC valves shine in lower-strength, corrosion-resistant scenarios. They’re a lightweight option for less intense environments, like moving water in irrigation.So, durability, environment, and cost matter when choosing. Stainless steel lasts, brass balances price and performance, and PVC brings cost savings for lighter duties. These details equip professionals with the clarity needed to pick the precise valve for their system’s heart.

Conclusion: Making the Right Choice in Ball Valves

Choosing the best ball valve is key. We’ve looked at many kinds, how they work, and what they’re made of. Like, tough stainless steel is great for high pressure, and PVC is good against rust. Need something strong and exact? Full port or V-port valves are your go-to. But getting the right valve means finding a top maker, like Dombor. They give you top-notch valves in big numbers, making your work run smoother. Studies say that with good valve suppliers, your systems can run 25% more without stopping. So, for those who want their stuff to last and do well, picking a good partner is a must.