Industrial valves have grown and changed over time, becoming different varieties with various uses. Each industrial valve type differs from the others in the unique qualities that make it ideal for use in a particular circumstance. Energy valves and their varieties operate similarly.

Energy valves have established themselves in the industrial sector and are widely used in other industries. This is a result of their distinctive traits. By reading further, businesses can discover more about the many kinds of energy control valves and their applications.

Get in touch with Dombor immediately to learn about the many energy industrial valves suitable for your particular requirements.

What Is An Energy Valve?

The energy valve is one of the market’s most contemporary types of valves. Two fundamental properties of this more advanced control valve distinguish it from the other valve offerings. The fact that it is electronically controlled is its primary feature, followed by the fact that it enables two-way pressure control that typically operates independently.

Utilizing energy valves has a lot of advantages for industries, buildings, and plants. Because it improves coil operations, this valve system lowers power generation usage at chilled water facilities and pumps. Additionally, it lessens the chance of coil overflow, which calls for less pump distribution. Ultimately, all of these impact the facility’s energy and operational costs.

How Do Energy Control Valves Work?

Energy valves are prominent in applications where a change in media flow dependent on pressure is necessary. These valves perform a fantastic job of controlling the flow of a medium when coupled with temperature and pressure sensors. An actuator, a water flow meter, a temperature sensor, and a 2-way valve disc are standard hardware components found in energy valves.

These parts enable the energy valve to assess the medium’s flow rate and modify it as necessary. Additionally, the aid of the sensor in calculating the amount of energy used during flow. These valves concentrate on restoring the flow to controlled circumstances because disturbances in the medium’s flow lead to many problems.

An energy valve operates according to a straightforward principle: it attempts to restore order in the system whenever it notices a change in the pressure or flow rate. The valve adjusts the flow in response to the pressure change until the necessary flow rate is required.

Although energy valves operate on a similar concept, their function varies slightly depending on the application, such as in LNG industries or power generation. The system’s primary objective in heating equipment is to keep the temperature steady or increase it to the desired level. As a result, the energy valve closes when its temperature sensors notice a decreased differential temperature throughout the coil. This decreases the flow rate, which allows the system to compensate for heat loss and prevent overflow. The flow returns to normal as the valve opens once it reaches the requisite temperature.

Cooling applications operate on a similar principle. The valve starts to close and reduce flow when the internal temperature of the system and valve falls below the required level. The system compensates for the energy loss when the flow is lower and sets the necessary temperature. The flow then resumes.

Different Types Of Energy Valves Based On Design

Depending on the applications, energy valves come in various kinds. Although these valves’ basic structure and operation are the same, they have unique components/parts for particular uses.

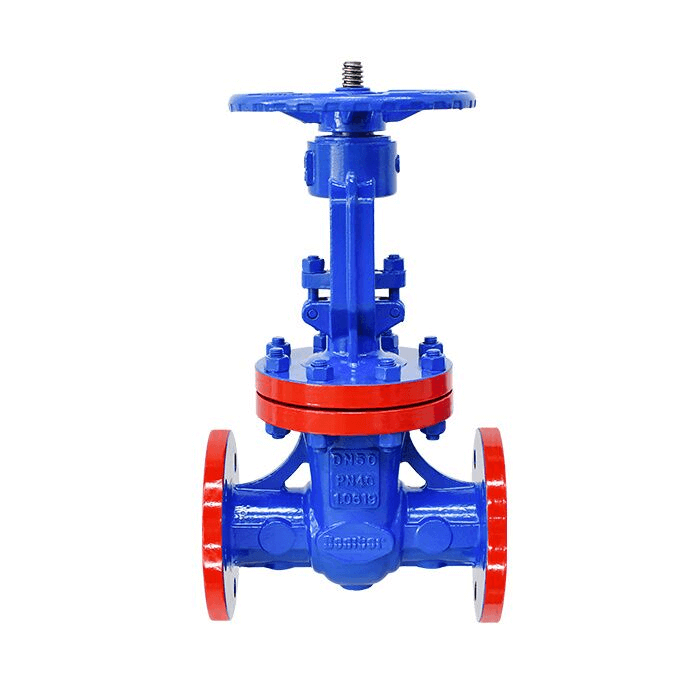

- Pressure Seal Gate Valve

The media flow path is blocked by a gate, a disc or a wedge used in gate valves. Gate valves are primarily used to isolate media with less restriction; they are not designed for throttling. The gate valve should only be used completely opened or fully closed to achieve maximum efficiency.

The isolation valve category includes both gate valves and globe valves. In times of emergency or during maintenance, these valves can block the flow of media. These may also link the media to additional process machinery or specify the media’s path.

- Pressure Seal Globe Valve

The globe valve is somewhat similar to the gate valve, but rather than using a wedged disc, it uses a disc that resembles a globe and controls media by turning it on, off, or throttling it. The primary use of this kind of valve is for throttling. The globe valve’s drawback is that a high flow rate medium cannot be used with it. Globe valves in power generation applications can effectively control the flow. The globe valve also has a straightforward design compared to other valves, simplifying maintenance. Low friction is produced by design, which eventually increases valve service life.

The kind of media, its flow rate, and how much control the valve will need to provide are all things to take into account when selecting globe valves. In addition, it’s essential to avoid taking the valve’s seat, disc, and the number of spins required to open and close it for granted.

- Pressure Seal Check Valve

The mechanical check valve is a backflow prevention device used in pipeline and piping systems. The one-way or non-return valve designation of a check valve refers to the fact that it only permits one direction of fluid flow. The concept of differential pressure underlies the operation of the check valve. It implies that the check valve will only operate if the upstream pressure exceeds the downstream pressure.

Anti-backflow devices include check valves. It permits a one-way flow of media, which is what this signifies. In addition to being able to adapt to material with high velocities, the 45-degree slanted disc design avoids water hammering. A low-pressure drop is also possible, thanks to the design. Check valves safeguard against potential reversal flow harm to the entire pipe network and associated machinery. As they are frequently more exposed to media and other operating difficulties, check valves may sustain the greatest damage of any valve type.

What Are Geothermal Valves Types?

Different kinds of power plants are being created to enhance energy output as the demand for renewable energy sources rises globally. Numerous countries rely on geothermal energy, one of the most plentiful energy sources.

Renewable energy sources are increasingly necessary as time goes on. Geothermal energy is a clean and sustainable power source since it is continuously created inside the ground. Geothermal energy production from renewable sources relies heavily on dependable, high-performance geothermal valves.

Geothermal power plants may produce renewable energy effectively, safely, affordably, and with little adverse influence on the environment when they have access to high-quality, dependable valves. It is essential that the geothermal plant is available; hence resilient valves with less maintenance are preferred.

Globe valves, industrial butterfly valves, and ball valves are a few of the often-used geothermal valves. There are other varieties, like geothermal solenoid valve, geothermal water valve, etc.

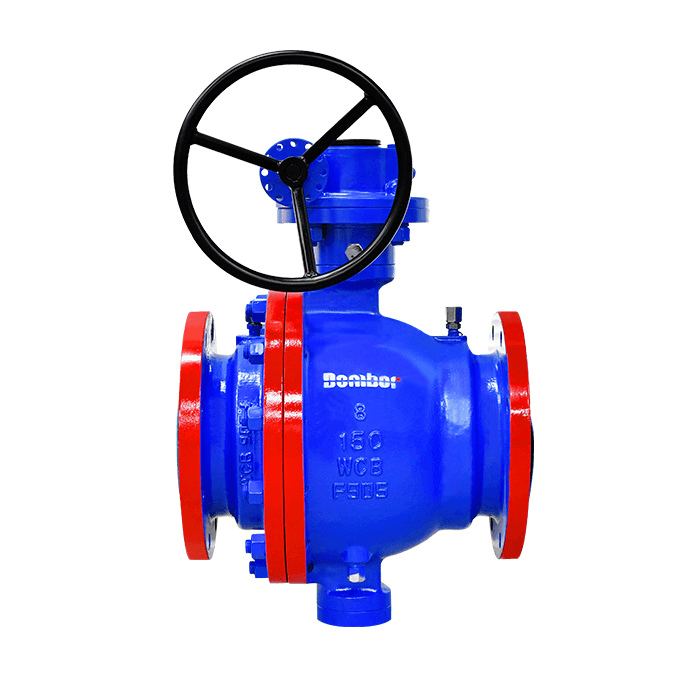

- Ball Valve

Industrial ball valves can be used for gas and liquid services. Due to their long service life and consistent sealing throughout that time, they are very well-liked in the petrochemical, chemical, and oil and gas industries. Even cryogenic and vacuum applications can make use of ball valves.

Using a hollow, rotating ball, a ball valve is a type of valve that controls the flow of a medium through itself. The valve is open if the ball’s hole is parallel to the flow. It closes when the ball is turned 90 degrees with the valve handle.

A ball valve’s primary purpose is to isolate distinct chambers, ducts, and pipes within a plumbing system by beginning, stopping, or altering the flow of a medium in the path. This can be performed by allowing the medium to flow entirely through the ball valve, partially via a smaller opening, or altogether stopping the flow.

Ball valves have recently undergone technological advancements that guarantee no scaling when utilized in power plants. These valves are reliable and have a long lifespan.

- Butterfly Valve

The use of butterfly valves is every day in geothermal power plants. Through the quarter-turn movement of a disc, a butterfly valve controls the flow of materials through enormous pipe widths. To regulate the motion of the disc, an actuator is attached to a rod that passes through the center of the disc. Both parallel and perpendicular to the media flow are possible for the disc location. Due to the disc’s constant presence in the flow, a butterfly valve differs from conventional valves in that any position of the valve results in a change in pressure.

In many geothermal power plants, butterfly valves are prominent. Older designs had scaling problems where sediments gathered inside the pipe system; however, using the most recent valve designs and versions ensures a smooth experience. Butterfly geothermal valves are one of the frequent choices due to their capacity to create tight seals. Additionally, these valves can effectively halt a medium’s flow.

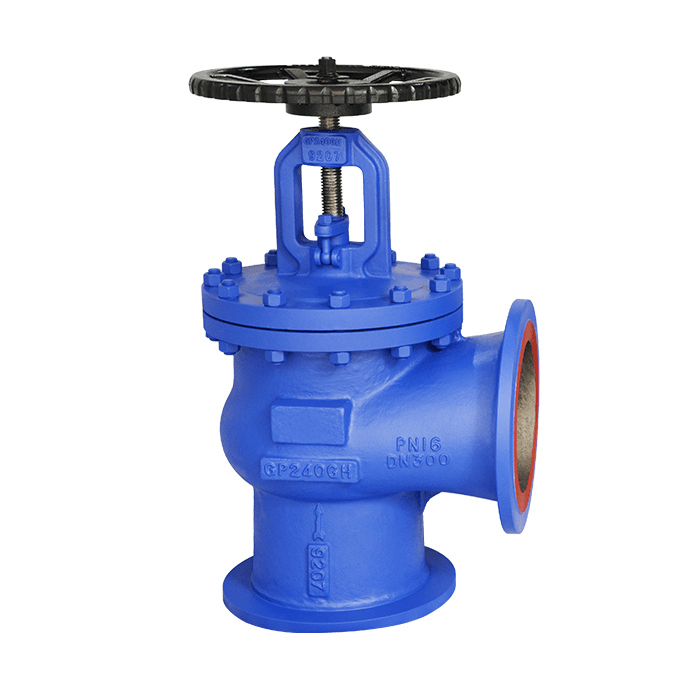

- Globe Valve

One of the valve types most frequently utilized in industrial settings is the globe valve. Controlling liquid and gas flow is one of the purposes of globe valves. They also efficiently control the pressure and flow direction in a system. Globe valves stand out from other types because they are adapsource:Dombor globe valveable and dependable, which makes them crucial for various sectors.

Globe valves, or geothermal flow control valves, are renowned for their robust design and longevity. This characteristic demonstrates that you can use these valves in industrial settings when other valves might not be appropriate.

The flow of liquid or gas via a plumbing or pipe system can be controlled with a globe valve. In industrial and commercial pipe systems, for example, they are frequently utilized in applications where precise flow regulation is necessary. One of the first varieties of valves, globe valves have a long history and have mostly kept the same in design.

Compared to other valve types, globe valves are more intricate and have a circular body with a moveable disc, or plug, that may be opened or closed to allow or limit fluid passage. The user can change the fluid flow since the plug is attached to a stem that a handle or lever can manipulate.

- Geothermal Zone Valve

Any geothermal system that uses a geothermal zone valve performs better overall. The flow to a specific plumbing circuit is managed using zone valves.

What Is A Solar Valve?

Utilizing the sun’s radiant heat and light to create thermal or electrical energy is known as solar power. Additionally, it is among the types of renewable energy that are the cleanest and most plentiful. It is produced using numerous methods, including energy and heating water for household, commercial, or industrial use.

When heated oil is poured through the systems of solar power plants, valves regulate the oil flow. Extensive bonnets are necessary to meet the temperature requirements because they assist in insulating the valve body. Additionally, the solar system functions in various global climates, including icy and arid areas. Therefore, in addition to meeting the immediate needs of the hot oil being utilized, the valves must also consider environmental considerations. They must endure, for instance, exposure to dirt, rain, snow, salt, cold temperatures, and various humidity levels.

As more businesses and energy providers turn toward a greener future, solar energy has emerged as a competitive alternative to supply the industry with its energy requirements. The solar valve must adhere to certain specifications for solar energy applications to operate safely.

- Solar Non-Return Valve

The stagnation temperatures within the solar collector panels are becoming a problem for modern plumbing systems as solar water heaters become more efficient. Installing a high-temperature solar non-return valve is necessary to prevent heated solar collector panel water from causing damage to the plumbing system’s plastic water pipes, pumps, and valves.

- Solar Ball Valve

All situations where managing high temperatures are required call for the usage of metal-seated ball valves. These valves, which are quarter-turn family members, are made to manage the on and off characteristics. Compared to other valves, ball valves, like side entry ball valves, have less seat wear.

- Solar Butterfly Valve

A solar butterfly valve is the type of solar solenoid valve that is best for isolating or regulating flow. Located in the middle of the valve body, the disc is the closing mechanism. The shaft, which extends from the disc and into the solar safety valve body at the top, connects the disc to a handle or actuator. Business owners can get the best valves from the best triple-offset butterfly valve manufacturer.

- Control Valve

The next generation of concentrating solar power plants needs an energy control valve to manage the solar energy they absorb. Collect, store, and convey the highly corrosive and heated chloride salt needed to safely and reliably produce energy for the general population safely and reliably. When collecting and delivering energy, molten salt maintains a constant temperature throughout the power plant. Flow-control valves are the piping system gatekeepers responsible for sending this collected energy to a power plant’s production side. These valves frequently experience shallow outside temperatures and are continuously exposed to harsh temperatures, pressures, and flow rates.

Materials Used In Making Energy Valves

A valve’s construction may employ a variety of materials. To obtain the optimal balance of usefulness and price, a typical energy valve manufacturer uses a lot of solid material that works perfectly fine in extreme conditions.

Energy valves prominently comprise these materials: cast iron, stainless steel, brass, and carbon steel because they are highly resistant to corrosion and wear and tear.

The procedure of sand casting is most frequently employed to create the valve’s body and disc from carbon steel. Duplex and austenitic stainless steel grades are the most frequent options for valve fabrication. In harsh service conditions, nickel alloys work best in energy control valve components. These alloys are especially helpful in severe, corrosive settings because they can prevent stainless steel from being damaged by destroying its protective oxide coating.

The nickel aluminum bronze alloys offer exceptional corrosion resistance, especially in areas with seawater. Additionally, they firmly oppose biofilm development, which can exacerbate corrosion issues with stainless steel. Titanium alloys are incredibly resistant to corrosion and have the highest strength-to-weight ratio of any metal. Like stainless steel, titanium alloys form a protective oxide layer on their surface, making them resistant to corrosion.

Components Of Energy Valves

The following are the components of energy valves:

- Body

It is a particular class of pressure vessels with an aperture, orifice, or both. The controlled liquid is permitted to pass through the valve’s body. Monitoring the behavior of flow regulation is helpful.

- Trim

The trim is another component of the energy valve that immediately contacts the fluid beside the body. The seat, plug, disc, and stem make up this component.

- Actuator

Electric and pneumatic actuators are the essential and prominent types of actuators.

- Pneumatic Actuators: To provide a modulating control action, pneumatic actuators require an air or gas signal from an outside source. A top port on the actuator transmits the pneumatic signal’s force. It then disperses the signal across the diaphragm of the actuator. The consequence is pressure being applied to the diaphragm plate by the diaphragm. Because of this, the control valve is actuated by lowering the valve stem.

- Electric Actuators: Motors play a crucial role in powering these actuators. They employ an electrical signal that can facilitate the rotation of the motor shaft. This motion changes into a linear motion, which aids in driving the valve’s stem to modulate the liquid’s flow.

- Bonnet

It offers a mounting surface for the actuator and guide and a path for the stem to travel through. The main component, packing, packing nut, and guide, are part of the bonnet. Between the bonnet and the stem, the packing serves as a fastener. It aids in stopping any leaks.

Factors To Consider When Selecting An Energy Control Valve

Choosing the appropriate type of energy valve for an application is crucial for safety and customer satisfaction regardless of the business.

- Quality

Low-quality solar or geothermal valves will not function in a power plant, which is such a demanding environment. They might be less expensive in the short term, but when you factor in all of the expenditures that come along with replacement—the valve, the labor, the shutdown, and so on—that inexpensive valve becomes an extremely costly investment.

Low-quality valves for geothermal energy can do much damage even when they function correctly. Filter bag clogs are a common result of typical power plant valves not functioning well in humid conditions. Leaks lead to disposal problems and vacuum reduction, which have the knock-on effects of decreasing plant productivity, increasing maintenance costs, and generally losing money.

- Application

The most important consideration when choosing the appropriate energy valve for your application is picking the right one. Incorrect valve sizing can cause problems with how well the valve or the system functions. The temperature, flow rate, and pressure at which the valve operates are also determined. In contrast to plastic ones, valves, in most cases, can tolerate high pressures and temperatures.

- Function

A business can choose the principal function of an energy valve when choosing one of its many functions, including backflow prevention and shut-off capabilities. Regarding energy control valves, their primary function is to manage the flow of media through a pipeline system while preventing pressure buildup.

- Manufacturers

Before purchasing solar or geothermal valves for your industrial or commercial demands, it is crucial to perform manufacturer research. Choosing the proper manufacturer is crucial to getting the highest-quality product when using valves for specific applications. There are several factors to consider when purchasing the best valves, from quality assurance to shipping and customer support services.

Contact The Industrial Valve Manufacturer To Get An Energy Valve

It could be challenging to locate a producer of industrial valves of excellent caliber. Not every producer is as knowledgeable in this area as Dombor valves. Contact Dombor right now to discover a variety of energy valves that are appropriate for your business’s specific needs. Dombor hand-picks products that meet global standards and will be suitable for businesses worldwide. As a result, enterprise owners looking to source energy valves can contact professionals such as Dombor to source quality products at budget prices.