As we wrap our minds around the various facets of piping systems, it becomes evident that the heart of any well-functioning system lies in its components. One such vital component is the swing check valve—a silent guardian that ensures unidirectional flow, protecting our systems from the chaos of reverse flow and the dreaded water hammer.

Introduction to Swing Check Valve Installation

Understanding the Importance of Swing Check Valves

Imagine you’re nestled in the heart of a grand library, where each book possesses knowledge pivotal to the library’s sanctity. Swing check valves are much like these books, unassuming yet essential. Their purpose is simple yet profound: to permit the flow in one direction, firmly standing guard against any reverse flow. It’s in this simplicity where their importance lies—a valve body and a valve seat working together to shield our systems, much like how simple words weave complex tales.

Personalizing Your Approach to Swing Check Valves

At 40, with years of experience etched into my hands and heart, I’ve learned that each installation is as unique as the pipes it serves. The essence of these valves, from the hinge down to the valve disc, becomes part of a larger narrative—a story of protection, efficiency, and unwavering dedication to functionality. Every pressure drop and flow direction they regulate narrates a chapter of security within the sprawling novel of our pipelines.

Pre-Installation Considerations for Swing Check Valves

Selecting the Right Swing Check Valve

Choosing the correct types of swing check valves is akin to selecting the right spice for a gourmet dish—it must complement and enhance. Stainless steel valves, with their resistance to corrosion and rust, may cater to systems like a knight’s shining armor, guarding against the harshness of chemicals like nitric acid and acetic acid. Spring check valves, with their crisp cracking pressure, might be better suited for systems that whisper rather than shout their needs.

Tools and Materials Needed for Installation

Embarking on the installation of a swing check valve is a task that marries precision with practical know-how. To ensure a seamless process, one must be equipped with the right ensemble of tools, each with a purpose as clear as a note in a symphony. Below is a table that outlines the essential tools and their specific roles in the installation of a swing check valve:

| Tools | Description |

| Pipe Wrenches | For gripping and turning pipes, ensuring a secure fit and proper alignment. |

| Sealant | To prevent leaks by securing joints, providing a watertight seal. |

| Torque Wrench | To apply a precise amount of torque to the valve’s bolts and nuts. |

| Gasket Cutter | For custom shaping gaskets to ensure a perfect match to the valve seat. |

| Pressure Gauge | To measure the pressure drops and ensure the valve operates within specs. |

Each tool is a protagonist in the story of installation, ensuring that every chapter—from aligning the valve body to testing the pressure—unfolds without a hitch. With these tools in hand, professionals can approach the task with confidence, backed by the silent chorus of a job well done.

The Anatomy of a Swing Check Valve

Components and Their Functions

Within the robust body of a swing check valve, each part plays a pivotal role. The valve disc, much like a skilled dancer, moves in rhythm with the flow rate, while the valve seat ensures a seal as true as a heartfelt promise. In their closed position, they are steadfast sentinels, and when open, they allow life—in the form of fluids—to pass through like the breath of spring.

How Swing Check Valves Work

To understand a swing check valve is to understand a piece of poetry in motion. The valve opens graciously with the flow and swings into a closed position when the fluid attempts to retreat, like a door that only swings one way. The rocker arm and hinge are the unsung heroes in this tale, the silent protagonists that ensure the narrative of flow remains uninterrupted.

Step-by-Step Installation Process

Measuring and Preparing the Pipeline

Before we usher in our valve, a stage must be set. Measuring the pipeline is as crucial as a maestro tuning his orchestra before a performance—precision is not just desired; it is required. With the pipeline’s inner workings laid bare, we understand its needs, its whispers, and its demands.

Ensuring Proper Alignment and Position

As you introduce the swing check valve to its new home, remember: alignment is the cornerstone of a harmonious relationship. An improper installation is much like a misstep in a waltz—a momentary lapse that can lead to a lifetime of complications. Ensure the valve body sits well, and the flow direction is respected, for even valves demand the dignity of facing the right way.

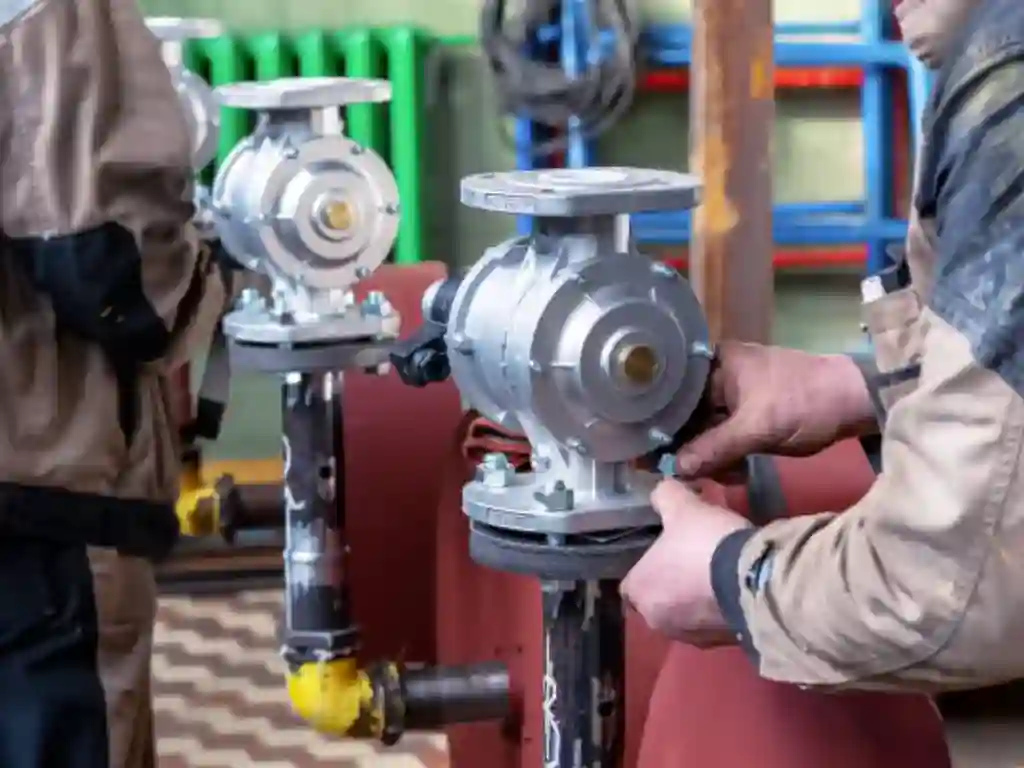

Inserting the Valve into the Pipeline

Gently, with the care of a sculptor placing the final piece upon his creation, the valve is set into position. It is not forced but persuaded, not commanded but invited. Each bolt is tightened with the precision of an artist, ensuring the valve disc is poised to respond to the fluid’s call.

Leak Testing Procedures

To test for leaks is to listen for the subtle whispers of betrayal. Water is a cunning escape artist, finding paths where none seem to exist. But with vigilance, leaks are discovered and corrected, ensuring the integrity of the system remains unchallenged.

Functional Testing of the Valve

A valve’s true test comes with the flow. Like watching the first leaves of spring respond to the breeze, the valve’s response to fluid flow is a dance of function and form. It is here, in the testing, that we find the swing check valve’s rhythm, the heartbeat of its existence.

Vertical Installation of Swing Check Valves

Positioning and Flow Direction Considerations

When it comes to vertical installation, the swing check valve faces a different set of challenges, akin to a climber facing the steep ascent of a mountain. The vertical position demands precision and an understanding of gravity’s role in the valve’s function. The valve disc, now a sentinel standing tall, must be aligned with the vertical flow, ensuring that it swings open and closed with the grace and accuracy of a pendulum.

Challenges and Solutions in Installation of Vertical Pipe

Vertical installations are fraught with potential pitfalls, much like navigating a ship through stormy seas. Issues of backflow and pressure drops loom like towering waves. However, with the right specifications and a keen eye for detail, these challenges are but stepping stones. Swing check valves designed for vertical flow, equipped with features like spring assistance, stand resilient against these trials, ensuring a steadfast performance.

Maintenance Tips for Swing Check Valves

Routine Inspection Guidelines

The key to longevity, in life and in valves, lies in regular care and attention. Routine inspections are the whispers of wisdom, the soft murmurs that speak of potential issues before they become roaring problems. Checking for signs of wear, corrosion, or leaks is akin to listening to the stories of an old friend—there is much to learn if one is willing to listen.

Cleaning and Lubrication Practices

The act of cleaning and lubricating a swing check valve is a ritual of respect, a testament to the value we place on its function. It’s not just about maintaining flow; it’s about honoring the role it plays in our systems. A well-lubricated hinge and a clean valve seat are the hallmarks of a system cared for with diligence and foresight.

Troubleshooting Post-Installation Issues

Identifying and Resolving Leakages

Leaks are the silent adversaries of any piping system, creeping in like uninvited guests. Identifying them requires a keen eye and a patient hand, much like a detective piecing together clues. Once found, resolving these leakages is a task of precision and patience, ensuring that the sanctity of the flow is restored.

Dealing with Valve Malfunction

A malfunctioning valve is a storyteller’s pause, a hiccup in the narrative of flow. It demands attention and understanding. Whether it’s a misaligned valve disc or a hinge caught in hesitation, each issue is a puzzle to be solved, a story to be set right.

Incorrect Sizing and Positioning

The tales of incorrect sizing and positioning are cautionary ones, reminding us of the importance of attention to detail. A valve too large or too small, or one installed in defiance of the flow direction, is a misstep in the dance of installation. Correcting these errors is not just a task; it’s an act of realigning the story to its intended path.

Inadequate Sealing and Fastening

The final seal and fastening of a swing check valve are the closing lines of a chapter, the full stop that marks the end of an installation tale. Inadequacy in this stage is like a story left unfinished, a narrative hanging in the balance. Ensuring a tight seal and secure fastening is the author’s final, satisfying flourish.

Cooperating with DomBor

In the realm of ensuring a one-way flow in your pipelines, DomBor stands as a beacon of reliability and expertise. Their swing check valves are not only easy to install and maintain but are also designed for high-pressure applications, ensuring that media overflow is a concern of the past. With a commitment to excellence, DomBor’s valves are crafted by seasoned engineers and meticulously tested for dependable functionality. For those seeking a partnership in excellence, DomBor’s responsive after-sales service and the assurance of a 24-month warranty period make them a wise choice for your swing check valve needs.

Conclusion: Maximizing the Benefits of Your Swing Check Valve Installation

As we draw the curtains on our journey through the world of swing check valve installation, we reflect on the key takeaways. From understanding the importance of these silent guardians to the meticulous process of installation, each step is a verse in the poetry of fluid dynamics.

Final Thoughts on Effective Installation Practices

In the end, effective installation practices are not just about technical precision; they’re about storytelling. Each swing check valve installation is a narrative woven with threads of knowledge, experience, and attention to detail. It’s a tale of ensuring one-way flow, of protecting systems from the chaos of reverse flow and water hammer, and of honoring the silent yet pivotal role these components play in the grander story of our pipelines. As we part ways, remember that each pipeline has its own story to tell, and each swing check valve you install is a character in that story. May your installations be narratives of success, and may the flow in your pipelines always be a tale of unidirectional triumph.