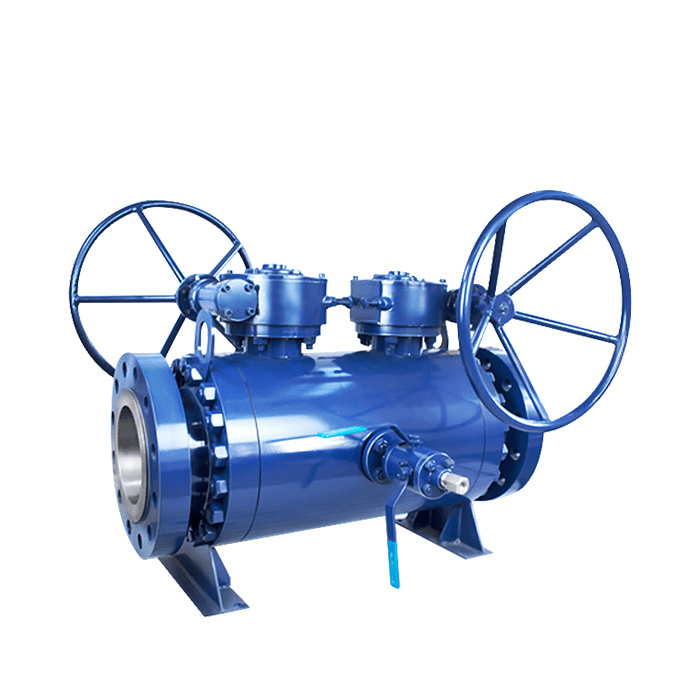

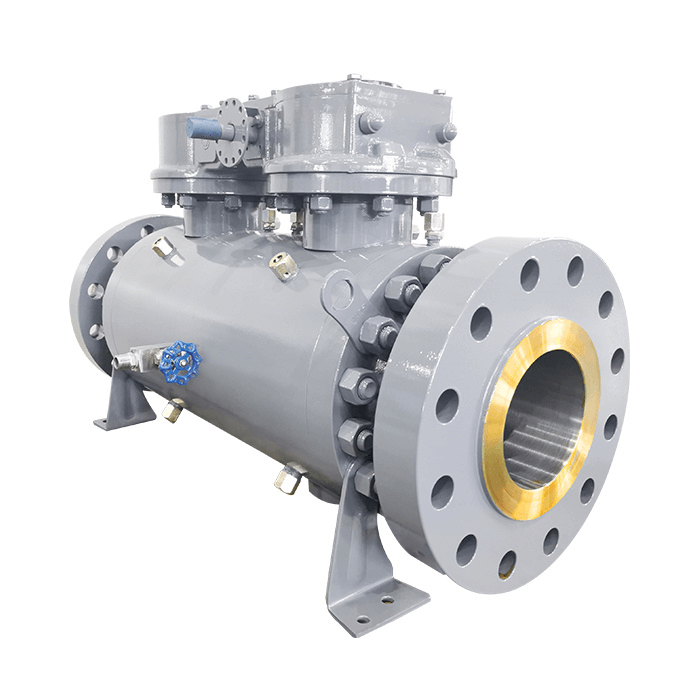

Components of the Double Block and Bleed Ball Valve

Some components of the double block and bleed ball valve are:

- Valve Body: Routing of the transmission of media through the valve is controlled by the valve body.

- Stem: The valve stem is solely responsible for the proper positioning of the disk.

- Seats: Moving components of the valve rest in the seats when it is at its closed position.

- Bonnet: Openings on the top of the valve body are covered by the bonnet. As a result, it serves as the pressure-retaining part of the valve.