Introduction to Petrochemical Valves

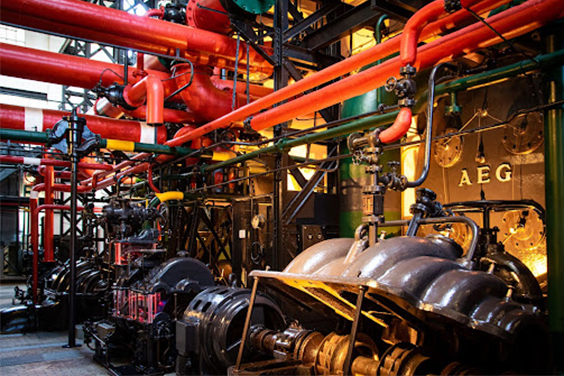

The petrochemical industry is a tapestry woven with countless threads, each holding its own against pressures and temperatures that dance to the tune of extremity. Within this intricate dance, petrochemical valves play a pivotal role, often understated, yet unmistakably critical. Imagine a petrochemical plant, its skeleton of pipes akin to arteries in a living organism. These pipes carry the lifeblood of the industry—fluids that can be as temperamental as they are necessary. Here, industrial valves stand as silent sentinels, ensuring that the flow of these vital substances is directed with precision. From gate valves to globe valves, each piece serves its purpose, allowing the plant to breathe and operate smoothly. Picture, if you will, a globe valve—its spherical body housing a disc type mechanism, rising and falling, dictating the passage of materials with the grace of a conductor. It’s not merely about on and off; it’s about modulating and regulating the symphony of operations that keep a petrochemical plant alive.

Importance of Safety and Efficiency

In a world where efficiency is king, petrochemical valves ensure that every second is accounted for, every minute devoid of unnecessary pause. And yet, amidst this clockwork precision, safety stands paramount. For what is a plant if not a gathering of potential, a place where the slightest misstep can lead to onsite explosions or uncontrolled releases of toxic chemicals? The valves in a petrochemical plant are more than mere components; they are guardians against chaos. Knife gate valves, with their sharp, sliding mechanism, can cut through the procession of thick materials, ensuring that not a drop is out of place. In the presence of high temperatures and high pressure, these valves demonstrate a fortitude that belies their static appearance.

Types of Petrochemical Valves

Delving into the world of valves is akin to exploring a hidden garden of mechanical marvels. Each valve, a bloom with its own distinct colors and purpose.

Automatic Shut-Off Valves

Automatic shut-off valves are the unsung heroes, often overlooked but keenly felt when they spring into action. In the face of danger, they react with a decisiveness that is the hallmark of years of engineering evolution. These valves do not hesitate, closing off lines in the presence of unwelcome pressure changes, their actions sometimes the thin line between normalcy and disaster.

Knife Gate Valves

Knife gate valves are the stalwarts in handling slurry and viscous materials. Their design, seemingly simple, hides a complexity that allows them to operate in conditions where other valves might falter. The knife, a blade that slices through resistance, stands testament to the ingenuity embedded in the petrochemical valve design.

Globe Valves

Globe valves, often described as the divas of the valve world, are recognizable by their spherical body and intricate internals. Their ability to modulate and regulate flow makes them a popular choice for applications demanding precise control. Like a seasoned pianist adjusting the tempo and dynamics of a piece, the globe valve ensures that every drop of material fluid is in harmony with the larger operation.

Check Valves

Ah, check valves! These are the gatekeepers, preventing backflow and ensuring that every fluid knows its place. Their design ensures that they only allow flow in one direction, a mechanism resembling the disciplined march of soldiers, unwavering and precise.

Ball Valves

Ball valves, with their distinct round mechanism, are the epitome of simplicity and efficiency. In the blink of an eye, they can transition from open to closed, offering an unobstructed path when needed and a solid barrier when called upon. Their compact shape and reliability make them a mainstay in many daily operations, ranging from the petrochemical sector to our very own households.

Butterfly Valves

Butterfly valves, as their name suggests, possess a beauty that transcends their utilitarian function. With a central disc that rotates to regulate flow, they offer an efficient solution that occupies less space than many of their counterparts. Their eccentric design ensures that the disc never entirely touches the body, minimizing wear and tear.

The Vital Role of Valves in Petrochemical Safety

To think of the petrochemical industry is to be reminded of its inherent risks. And within this volatile environment, the role of petrochemical valves can’t be understated.

Prevention of Leaks and Spills

Leaks and spills are more than mere accidents; they’re events that can mar the reputation of a company, lead to substantial financial losses, and pose severe environmental threats. Valves, with their stringent leakage precautions, stand as the first line of defense. Be it the butterfly valve ensuring a tight seal or the check valve vigilantly guarding against backflow; each valve plays its part in upholding the industry’s integrity.

Emission Control

In an era of increasing environmental consciousness, controlling emissions isn’t just about compliance; it’s about corporate responsibility. Petrochemical valves, especially those tailored for gas industry applications, ensure chemical control and harmful emissions are kept in check, contributing to a greener planet.

Controlling High-Pressure Environments

Pressure, if uncontrolled, is a ticking time bomb. Petrochemical valves are specifically designed to thrive under extreme pressure conditions, ensuring that even in the most intense scenarios, safety isn’t compromised.

Valves and Efficiency: A Symbiotic Relationship

In the heart of a petrochemical plant, efficiency weaves through the machinery like a golden thread, and valves are the loom on which it is spun.

Reducing Operational Downtime

Downtime in a petrochemical plant is the silent thief of time and resource. Valves, with their robust design and high precision, play a critical role in minimizing this unwanted guest. A well-chosen valve, such as a ball valve with its swift operation, can mean the difference between a smooth transition and hours of stalled productivity.

Enhancing Flow Control

The flow of fluid within the industrial veins must be precise—a dance between too much and too little. Valves, like the globe valve with its fine control, ensure that this balance is maintained, enhancing the efficiency of the entire system.

Material Considerations for Durable Petrochemical Valves

In the realm of petrochemical valves, the choice of body material is not merely a decision; it’s a declaration of intent, a commitment to longevity. The battle against corrosion is a relentless one. Valves are often at the forefront, exposed to a variety of materials, some of which are highly corrosive. The use of corrosion-resistant materials in valve components is not just prudent; it’s imperative for the valve’s longevity. Petrochemical plants are no strangers to high temperatures. Valves designed to withstand these conditions, such as those made from specific alloys, ensure that even when the heat is on, performance and safety are not compromised.

Installation and Maintenance of Petrochemical Valves

The narrative of a valve does not end with its design or material; it continues through its installation and maintenance.

Best Practices for Valve Installation

Installation is the first step in a valve’s life cycle. Adhering to best practices during this phase is akin to setting the stage for a flawless performance. It’s about ensuring that every valve is positioned and calibrated to deliver its best.

Maintenance for Long-Term Reliability

Maintenance is the unsung melody of longevity in the petrochemical industry. Regular checks and timely repairs ensure that valves continue to function with the same efficiency and safety as they did on day one.

Selecting the Right Petrochemical Valve for Your Needs

In the vast sea of valves, selecting the right one for your petrochemical plant can seem daunting. But it need not be a journey you take alone.

Understanding Plant Requirements

Each plant is unique, with its own set of challenges and needs. Understanding these requirements is the first step in selecting a valve that not only meets but exceeds expectations.

The Consultative Approach to Valve Selection

The selection of a valve is not a decision to be made in isolation. It’s a consultative process, a dialogue between the plant’s needs and the expert’s knowledge. It’s about finding that perfect fit—a valve that aligns with the plant’s rhythm.

Wrapping it up

In the challenging world of petrochemicals, where extreme temperatures can soar to 500°C and pressures vary from a low pressure of 50 psi to a staggering 5000 psi, the role of valves is pivotal. Consider slide gate valves: standard valves may falter, losing 10% efficacy at 3000 psi. Yet, high-caliber valve works ensure up to 99.5% efficiency even under 5000 psi. This isn’t merely about stats—it’s about the safety valves ensuring uninterrupted operations in fairly dangerous places.For businesses eyeing a robust future, collaborating with seasoned petrochemical valve manufacturers is essential. Choose DomBor for excellence in valve solutions. It’s not merely meeting the standard but setting the bar higher in the piping system, where safety and proficiency are always prioritized.