Introducción

Gate valves, butterfly valves and check valves such as gate valves, butterfly valves and check valves are used throughout many industries to regulate the flow of liquids and gases. One of them is swing check valve which is mostly employed in preventing backflow. You might be wondering, “What is a swing check valve, and why is it so commonly used?” This ultimate article will take you through basic things about swing check valves such as how they function, types available and where they are applied across different sectors.

What Is a Swing Check Valve?

Swing check valves are one of the types of check valves which allow fluid to flow in only one direction but automatically prevent backflow. They function by having a hinged valve disc that swings open with forward flow and closes when the flow changes direction, thus ensuring unidirectional movement. Swing checks are employed in various applications where stopping reverse flow is critical, such as piping systems, wastewater treatment and firefighting equipment. Due to their ease and dependability, they have been favored across multiple sectors.

Next, we will discuss further the operation principle of swing check valves that makes them work well in regulating fluid flow.

How Does a Swing Check Valve Work?

A swing check valve works by the use of fluid dynamics and pressure differences. When the fluid flow starts from the inlet side, the upstream pressure acts on the disc and makes it to open. This motion enables the fluid to flow through with ease and therefore ensuring the low pressure drop across the valve. In cases where the flow direction has to be maintained in a particular direction, such as in wastewater systems or sewage systems, this feature works very well.

When the flow pressure reduces or there is a flow reversal, the disc returns to the closed position to avoid back flow. This automatic closure is important in avoiding water hammering, a situation where a flow of fluid is suddenly stopped and this results in a pressure wave that may harm the piping system. When the right type of check valve is chosen, especially those that are high pressure or have unique modification requirements, the swing check valve provides protection against such problems. This design coupled with a strong valve body and a well designed valve seat guarantees the best performance of the valve regardless of the pressure difference.

Swing check valves are different from other types of check valves like ball valves or spring check valves in the direction of the flow control. Their design does not allow for flow pressure disruptions, which is useful in wastewater applications where flow reversal must be quickly resolved. Thus, the knowledge of the dynamics of swing check valve operation will help engineers to control the effects of water hammer and prolong the service life of the systems.

Key Components of a Swing Check Valve

The swing check valve is made up of several parts that are very vital in the proper functioning of the valve. Let’s break down each key part:

- Cuerpo de válvula: Valve body is the outer shell of the valve that contains all the internal parts of the valve. It is usually constructed of heavy materials such as stainless steel, cast iron or bronze depending on the nature of the media being regulated. The valve body gives the necessary support and also shields the internal parts from external conditions such as corrosion or mechanical impacts. Its material selection is vital in order to guarantee that the valve will be able to handle the pressure and temperature range that it will be exposed to in the system.

- Valve Disc: The valve disc is the part of the valve that rotates in a manner that opens or closes depending on the direction of the flow of the fluid. The valve disc is usually manufactured from stainless steel or other materials that are resistant to corrosion since the disc is always in contact with the fluid passing through the valve.

- Asiento de válvula: Valve seat is the internal component of the valve body on which the valve disc comes to rest when the valve is in the closed position. It has a very important function of sealing the valve to avoid back flow. The valve seat is often made from a hard wearing material such as metal or a composite to ensure that it does not wear out quickly and to ensure that the valve seat is a tight fit. The quality and precision of the valve seat are critical to the performance of the valve because any defects in the valve seat will cause leakage and poor performance.

- Hinge Mechanism: The hinge mechanism is used to join the valve disc with the valve body so that the disc can open and close. This part is vital for the movement of the valve and is expected to endure the cycles of operation throughout the life of the valve. The hinge is usually made of the same material as the valve disc or the valve body to ensure strength and corrosion resistance. The position of the hinge and the design of the hinge are critical in the operation of the valve and the amount of wear on the valve disc and the valve seat.

Types of Swing Check Valves: Top-Hinged vs. Tilting Disc

It is important to know the difference between the top-hinged and the tilting disc when choosing a swing check valve for your system. These two types both provide the fundamental function of enabling the passage of fluids in one direction only and preventing backflow but they have different operational features and therefore are appropriate for use in different applications.

Válvulas antirretorno de charnela superior

Top-hinged swing check valves are of conventional design. The hinge is situated at the top of the valve body and links it to its disc part of the valve. Therefore, this disc opens when the inlet pressure increases and it closes by gravity with the help of back flow pressure if the flow pressure decreases or becomes negative. This design is suitable for low pressure systems where pressure drop is of essence. However, because there is a hinge on which its disc rests, there is always a slight delay in closing, which may lead to water hammering under certain conditions. It is often used in horizontal flow or where basic valve operation and low cost are expected through high usage.

Válvulas antirretorno de disco basculante

On the other hand, tilting disc swing check valves are designed for more accurate flow control. Unlike other check valves that fully open and close, tilting disc swing check valves have discs mounted on pivot points, which allows them to tilt. This design helps them respond faster to flow reversal, reducing the risk of water hammering. As a result, they offer better control over fluid flow. Tilting disc valves are often used in sanitary systems or wastewater treatment plants. The tilting action allows for a more gradual closure, which minimizes pressure wave formation and enhances the longevity of the valve. While these valves are more expensive due to their complex construction, they provide superior prevention of reverse flows. They are especially suitable for applications that require high pressure.

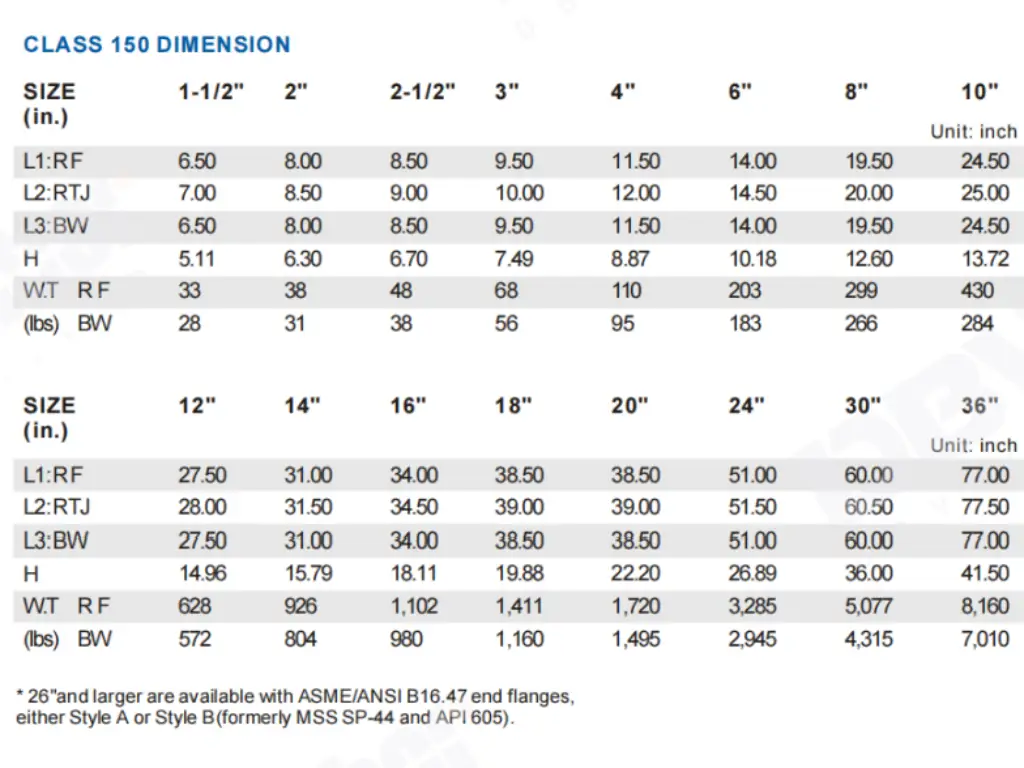

Below is a chart showcasing some key parameters of swing check valves from the manufacturer Dombor. For those interested in more detailed specifications, you can explore the full swing check valve list here for comprehensive information.

Advantages and Disadvantages of Swing Check Valves

Swing check valves are used in many industries because of the following benefits. One of the major ones is their simplicity as they run on their own depending on the flow conditions and hence do not need much or any manipulation or power from the outside. Therefore, they are very reliable in applications where reliability of the equipment is paramount. In addition, swing check valves are used in various types of media such as liquid, gas, and even semi-solid in sewerage systems and wastewater treatment.

However, there are some disadvantages that are associated with these valves. For example, swing check valve may be vulnerable to water hammer effect which is a shock wave that occurs when a valve shuts down rapidly across the pipe system. If left unattended to this can cause damages. In addition, although swing check valves are very useful in avoiding backflow, they are not as useful in high pressure conditions that are suitable for other types of check valves such as spring check valves or silent check valves. Knowing these positives and negatives will assist you in deciding whether you should use a swing check valve for your application requirements.

Common Applications of Swing Check Valves Across Industries

Swing check valves are widely used in many industries due to their function of avoiding back flow and ensuring the fluid flow in one direction only. Due to their flexibility, they can be used in several important applications.

Swing check valves are widely used in water and wastewater treatment plants, and are one of the most popular types of check valves. In these systems, it is important to maintain a flow direction in order to avoid contamination and to have the system work properly. For instance, in a municipal wastewater treatment plant, swing check valves assist in controlling the pressure of the flow and the back flow that may cause pollution of clean water sources. These valves can operate with very low pressure drops and this makes them suitable for such applications where low pressure is usually experienced.

Another important use is in pump systems especially in flood control systems. Swing check valves are used on the suction side of the pumps to ensure that water does not flow back to the source when the pump is turned off. This is important in avoiding water hammering, which is destructive to the piping and other parts. These valves are very important especially in areas that are near the sea or river where flooding is common to prevent back flow of water into the system which may damage infrastructure and the environment.

Swing check valves are also used in the industria petrolera y del gas. In these high pressure environments, the valves are essential in avoiding the back flow of oil or gas, which may lead to build up of pressure. For example, in offshore drilling platforms, swing check valves are used to control the flow direction of the extracted resources for safety and functionality.

These examples show how swing check valves are used in different industries such as water treatment, oil extraction and many others. They are very useful in both high and low pressure systems because of their ability to offer flow control and back flow prevention under various circumstances.

Installation and Maintenance Best Practices

Swing check valves should be installed and maintained correctly to guarantee that they will work effectively in the long run. When installing these valves, one has to ensure that the flow is in the right direction and the position of the valve. For example, in horizontal flows, the valve should be fitted with the hinge at the top to help gravity in closing the valve. In vertical upward flow, the valve should be placed in such a manner that the flow assists in the opening of the valve and the stopping of the flow closes the valve.

Maintenance entails periodic checks on the valve disc, valve seat and hinge mechanism to determine their condition in as far as presence of debris and wear is concerned. These components can wear out or get damaged and this will lead to leakage or failure of the valve to shut as it is supposed to. It is also necessary to observe the system for water hammer and this can be controlled by changing the position of the valve or incorporating other measures of control. By adhering to these best practices, you will be able to optimize the performance of your swing check valve and integrate it into your system efficiently.

Choosing the Right Swing Check Valve for Your Application

It is important to grasp the advantages of swing check valves to be able to apply them in the various industries effectively and safely. Dombor, the No. 1 industrial valve manufacturer in China since 2001, has over 3,000 projects of experience especially in oil and gas and chemical industries. This guarantees that you receive the best solution for your needs since they are professionals. Are you ready to improve the dependability of your system? Call Dombor today to get the right swing check valve for your needs.