Introducción

In as much as the functionality of plumbing systems, industrial facilities, and even home piping is concerned, valves are very crucial. Some of the most popular types of valves include the check valves and the non-return valves (NRVs). These devices may look like the same to an ordinary user, but they are different and have their own characteristics. In this article, we will be discussing about check valve vs non return valve, going deeper into their working, usage and differences. At the end of the article, you will be in a position to determine which valve is appropriate for a given application.

The goal here is simple: prevent backflow and guarantee that the fluid only flows in one direction in your system. But which valve does the job better? The answer is in the knowledge of the specifics of the operation and usage of these two types of valves, their strengths and weaknesses. Now let us look at each of them in detail.

What is a Check Valve? Understanding Its Purpose and Mechanism

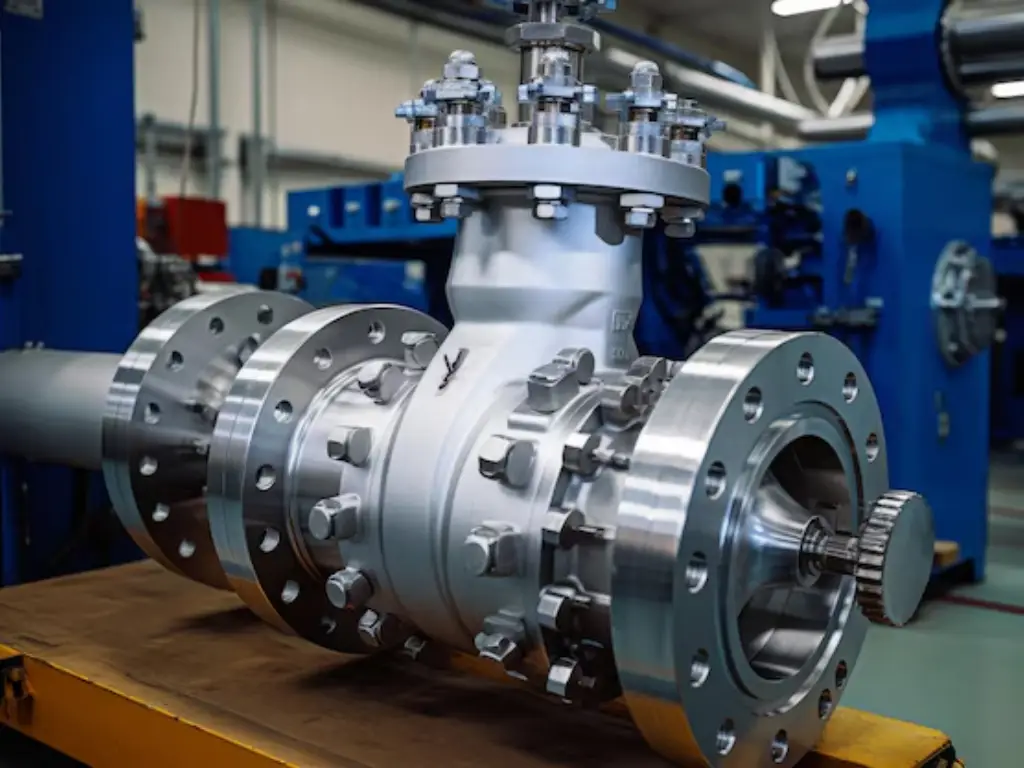

A check valve is a kind of valve that is used to allow the flow of fluids such as water, gas or oil in one direction and does not allow the flow in the opposite direction. The primary function of this valve is to prevent backflow which may lead to contamination, system failure or even equipment damage. It is commonly used in different fluid systems including pipelines, hydraulic systems, and wastewater management systems. Check valves do not require any form of control since they open and close depending on the flow and pressure of the fluid.

The simplest form of check valve has a moving part (disk or ball) that lifts when the forward flow of the fluid is in operation. When the flow is in the opposite direction, the valve shuts to ensure that there is no back flow. There are different types of check valves including the swing check valves, ball check valves, and the wafer check valves, all of which are designed for different uses. They are widely applied in industries that involve backflow prevention and flow control, particularly when dealing with fluids under pressure.

What is a Non Return Valve? Detailed Overview and Key Features

A non-return valve (NRV) works in a similar way to a check valve in that it permits the flow of fluids in one direction only and does not allow them to flow in the opposite direction. However, although they are used for the same basic purpose, non return valves are used in more specific applications where the prevention of reverse flow is important such as in water installations, sewage and miscellaneous process systems. The non-return valve works based on the pressure difference between the inlet and outlet of the valve. This valve opens when the pressure on the inlet side is higher than that on the outlet side. When the pressure is reversed, the valve closes tightly to prevent reverse flow.

One of the advantages of NRVs is that they are very effective in avoiding backflow. They are usually made of materials such as stainless steel and are built to work with various types of fluids ranging from water to oils and even gases. NRVs are usually used in systems where there is a continuous flow of fluids like pipelines, pumping systems and hydraulic systems. The structure of the valve may be different depending on the type of the fluid and the general needs of the system.

Check Valve vs Non Return Valve: Similarities in Design and Function

Having discussed both in detail, you will realize that check valves and non-return valves are quite similar. The two types of valves have the same basic function which is to allow fluid flow in one direction and prevent flow in the opposite direction. Both are self-acting, working on the principle of pressure variation without requiring any manual intervention. Also, both of them have parts that are capable of moving depending on pressure differences and fluid flow. This makes them suitable for a number of fluid systems, whether it is water, gases or oils.

As for the design, both valves can be of different types including the swing check valves, ball check valves or the diaphragm types and can be made from similar materials such as the stainless steel, PVC or brass. They are also commonly employed in water supply systems, sewage systems, and other applications where prevention of backflow is critical. This is the reason why the terms “check valve” and “non-return valve” are used interchangeably quite frequently.

Key Differences Between Check Valve and Non Return Valve

Although check valves and non-return valves are used for the same purpose, there is a distinction between the two that makes one suitable for use in a particular application than the other. Now, let us discuss these differences in terms of application, design, and pressure handling capacity.

Application Versatility

Check valves are more general and can be found in many systems. Some of the most common uses of valves include flow control, pressure control, and backflow prevention. This is because they can work with different fluids including water, gas and oil making them suitable for use in industries such as pipelines and hydraulic systems. Non-return valves (NRVs) are, however, generally more specific in their application. They are mostly applied in situations where there is a need to avoid contamination or backflow, for instance in the sewage systems or plumbing systems. These are easier to use and are therefore more appropriate for systems that have relatively simple backflow prevention requirements, especially where there is a risk of contamination. To get more information about the uses of non-return valves and check valves, please read the following sections of this article.

Design and Maintenance

The design of a check valve is usually more complicated and there are various types of check valves such as the swing check valves or the ball check valves which are suitable for high pressure systems. This complexity enables check valves to work in high pressure systems and conditions such as water hammer and pressure surges. On the other hand, non-return valves are relatively simpler in design and have fewer parts that can be replaced, but they are not as durable as the ones with check valves in systems with fluctuating pressure or different types of fluids.

Manipulación de la presión

Check valves are particularly useful in high pressure systems because they are capable of handling upstream pressure and manage pressure differentials. These are usually used in applications that require high pressure fluid flow and where the failure of the system may result in a lot of losses. On the other hand, non-return valves are more appropriate for low pressure systems than high pressure systems. These are less complex structures and therefore they do not pose much of a problem when it comes to flow resistance especially where pressure is low. In low-pressure systems, the simple structure of a non-return valve with streamlined mechanism does not allow pressure drops and provides reliable work without additional elements.

These differences in the use of check valve vs non return valve show that each of the valves has its advantages in certain pressure and fluid conditions and therefore it is important to know which valve to use in a certain application.

Applications of Check Valves: When and Where to Use Them

Check valves are very useful and are used in many sectors of industry and commerce. One of the most frequent applications is in plumbing systems, where they stop the polluted water from getting back into the potable water supply, thus protecting people’s health. They are also used in hydraulic systems where they help in the control of the fluid flow under pressure to enable the system to work effectively. Furthermore, they are employed in dump lines, compressors, and sewage systems to regulate the flow of fluid and to avoid the effects of back flow.

Check valves are also used in industries especially in the pipeline systems that convey gas or oil. In this case, backflow prevention is crucial in order to prevent system failure or contamination. In such critical applications, it is imperative to select the most appropriate type of valve, be it a wafer check valve or a ball check valve. They are ideal for use in applications that require handling of high pressure and pressure control to avoid pressure build up.

Applications of Non Return Valves: Ideal Use Cases and Scenarios

Non-return valves are another type of valves that are almost similar to check valves but are used in certain conditions. The most frequent use of this valve is in water fittings and plumbing systems to avoid the contamination of potable water supplies by backflow. You will also see them used in wastewater systems where it is imperative that the contaminated water does not flow back into clean water systems. These valves are suitable for low pressure applications and are commonly used in residential water supply and drainage systems, and sewage systems where pressure changes are not very frequent.

Furthermore, non-return valves are also applied in miscellaneous process systems and pumping systems where the main purpose is to avoid the backflow of liquid during the shutdowns. They are also easy to install and are therefore used in many industries for backflow prevention in small or relatively simple systems. These are easy to operate without the need for much attention, thus making them ideal for fluid systems that need to run for long without much interference.

How to Choose Between a Check Valve and a Non Return Valve: Key Considerations

When deciding between a check valve and a non-return valve, consider the following key factors to ensure the right choice for your system:

System Pressure

- If your system is subjected to high pressure or pressure fluctuations and water hammer, a check valve is preferable because of its construction and performance under such conditions.

- For low pressure systems where there is little or no resistance and where basic backflow prevention is required, a non-return valve is recommended. It has a simple structure that does not create a lot of pressure drops while in use and is very effective.

Tipo de fluido

- Check valves are versatile and can work with water, gas, and oil among other fluids and are therefore used in industries that deal with pipelines and hydraulic systems.

- Non-return valves are commonly employed in relatively simple systems, including plumbing and sewage, where the main objective is to avoid backflow.

Complexity and Maintenance

- Check valves are likely to have more parts in motion and therefore are likely to wear out and may need frequent servicing in high pressure systems.

- Non-return valves are relatively simpler in design as they have fewer parts and this makes them easy to service, especially in low pressure systems where the valves are expected to function optimally for long periods.

Consideraciones económicas

- Non-return valves are relatively cheaper for basic and low pressure systems while check valves may be expensive to purchase but are efficient in complicated or high pressure systems.

Dombor: A Leading Manufacturer of High-Quality Industrial Valves

As the No.1 industrial valve manufacturer in China since 2001, Dombor has successfully completed over 3,000 projects with 2,000+ satisfied clients in 140+ countries. Their extensive experience and commitment to quality make them a trusted partner for all your valve needs. Explore Dombor’s range of valves today to find the perfect solution for your system!