Introduction

A number of valves are used in industries. Some examples include globe valves, gate valves and ball valves. Of all these, the butterfly valve is extensively employed because its design is uncomplicated and it is cost effective. And maybe you could ask yourself: what exactly is a butterfly valve? Many piping systems require this versatile valve so as to effectively control fluid flow. This write-up will explore several key things about butterfly valves including their operating principles, various types and most popular applications for them. So here we go inside on why people like butterfly valves in different industries.

What Is a Butterfly Valve?

A butterfly valve is a quarter-turn valve that control flow of fluid in a pipe. It has a circular metal disc which is mounted on a turning shaft. When the valve is closed, the disc blocks fluid flow. When it is in the open position, the disc rotates to allow flow. Butterfly valves are popular for their simple designs, lightweight and affordable prices compare to other valve types.

Next, we will discuss further the operation principle of butterfly valves that makes them work well in regulating fluid flow.

Working Principle of Butterfly Valves

Understanding the working principle of butterfly valves enables one to appreciate their effectiveness and simplicity. The metal disc is in the center of the pipe and is connected to an external operating mechanism via a valve stem. When the valve is in the closed position, the disc lies at right angles to the flow direction and essentially stops the fluid from flowing.

Opening of the valve involves rotating the disc by a quarter turn till it becomes parallel with flow. Thus, allowing unimpeded passage of fluid. This operation for a quarter-turn is fast and easy, hence having accurate regulation of flow rate. The cam action of the valve stem gives a tight seal when closed, making it suitable for low pressure systems as well as high pressure systems.

Butterfly valves are versatile enough to handle various application needs due to their capability to handle different temperatures and pressures. Their designs reduce turbulence and pressure drop leading to effective flow control. This efficient mechanism has made butterfly valves become common industrial fixtures from water supply to wastewater treatment among industries.

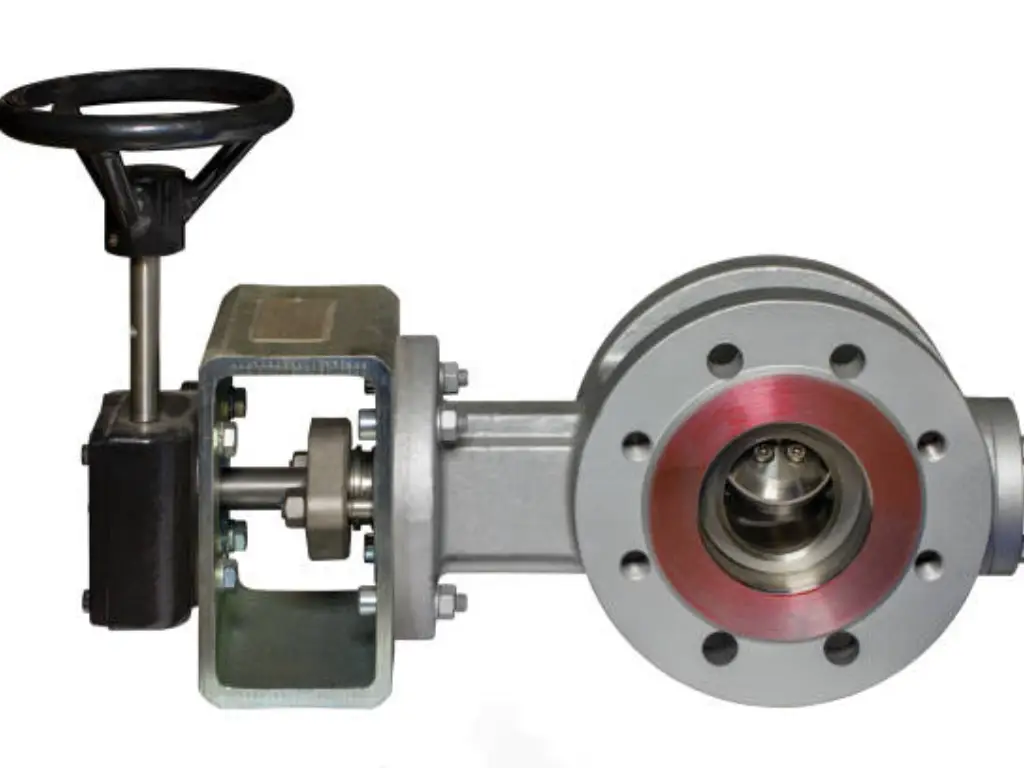

Key Components of a Butterfly Valve

Butterfly valve consists of several major parts, each of them playing crucial roles in its operation and performance. Knowing these parts is useful when selecting the right valve for specific applications as well as ensuring that the maintenance is done correctly.

- Valve Body: Inside the valve body are all internal components while it connects to pipe flanges. It provides structural support and should be strong enough to withstand operating pressures as well as environmental conditions. The body may be manufactured from such materials as reliable stainless steel, cast iron or PVC depending on applicant’s needs.

- Disc: The metal disc rotates to open or close the entire valve. Located at the center of the pipeline, this component can be made of different materials including stainless steel type, rubberized or plastic units among others depending upon media or working environments. Proper sealing and minimum wear are facilitated by proper valve designs and disc materials.

- Valve Stem: This shaft or valve stem links up with the disk to an exterior operator. Torque is transmitted through it from actuator or manual handle to let the disk spin around. Durability and strength are required for stem which is usually produced using stainless steel owing to corrosion resistance and mechanical wearing cannot affect it easily.

- Valve Seat: The valve seat provides a sealing surface for the disc when the valve is in the closed position. It can either be a soft seat which is made from rubber or Teflon suitable for lower pressure and temperature applications or it could be a metal seat meant for higher temperature and pressure. This ensures proper seal without any leakages.

- Actuator: The actuator is what moves the valve. It can be operated manually, electrically, pneumatically or hydraulically. The choice of an actuator will depend on how much control and automated systems are needed by the process owner. Manual actuators are modest and inexpensive while electric or pneumatic actuators are accurate and enable integration into automated systems.

- Body Seal: The body seal prevents leaks between the valve body and pipeline. This is important because it maintains piping system integrity thus preventing loss of fluid/matter contamination. Body seals must endure media exposure at any given operating condition hence material compatibility should be well considered for reliability purposes so as to enhance durability also.

Types of Butterfly Valves

There are a variety of Butterfly valves, each having different types specifically fashioned for particular functions and industries. With these kinds in mind, you can now choose the right valve for your application.

Wafer Butterfly Valves

These are the commonest type that fits between two pipe flanges. It is put in place by pipe flanges and requires fewer bolts compared to other types of butterfly valves. This wafer type butterfly valve provides a dependable seal against bidirectional pressure, thus preventing backflow. Its compactness and ease of installation make it suitable for water supply and sewage treatment applications.

Lug Style Butterfly Valves

Lug-type valves have threaded inserts (lugs) on their bodies that allow them to be installed using bolts which connect directly to pipe flanges. This design allows for installation of the valve at the end of a pipeline or between two flanges. Lug butterfly valves are commonly used in fire-protection systems as well as in industrial applications where system isolation is required for maintenance or repairs.

Double Off Set Butterfly Valves

These ones are also known as high performance butterfly valves because they have two offsets from centerline of the disc and the body of the valve respectively. This design helps reduce friction and wear between disc and seat, resulting in a longer life span and better sealing performance. Double offset butterfly valves are better suited for higher pressure and temperature applications such as those found in power generation, chemical processing industry, oil and gas sectors etc.

Triple Offset Butterfly Valve

Triple offset butterfly valve has three offsets: two similar to double offset and an extra one that forms a conical sealing surface. This eliminates almost all contact between disc and seat hence little wear and no leakage occurs. Triple offset butterfly valves can best meet critical application calling for highest level reliability and performance examples being refining process, cryogenic services and power generation among others.

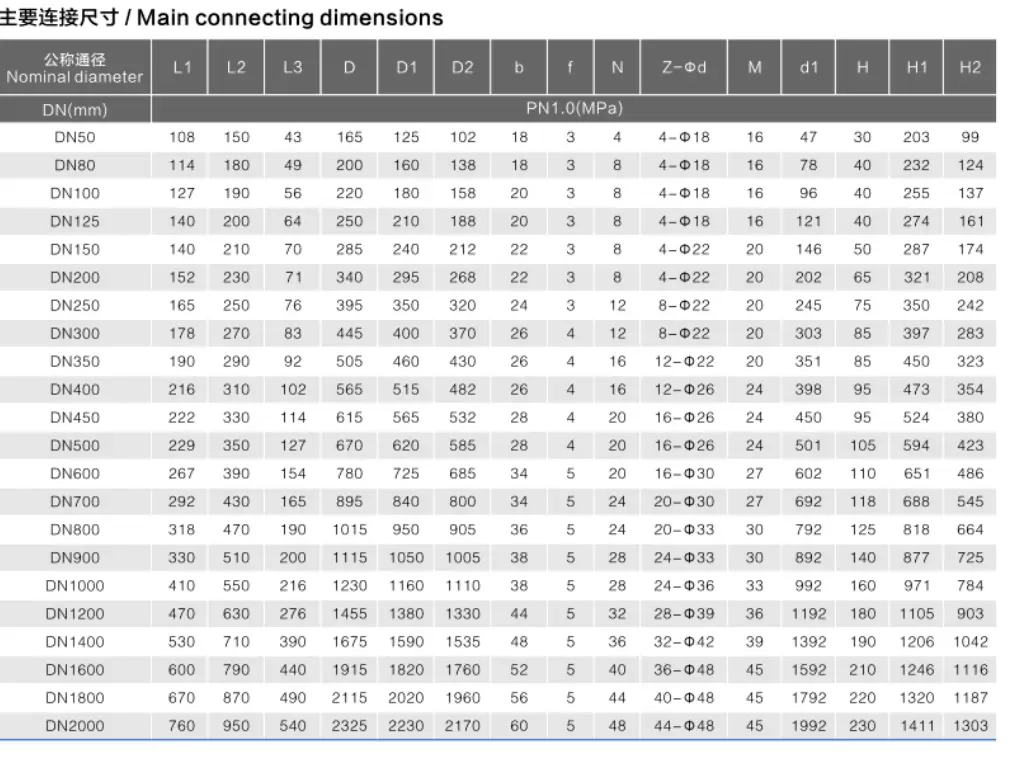

Below is a product parameter table (partial) about triple offset butterfly valve from Dombor to help you choose the right types of butterfly valve for your applications. To obtain additional and comprehensive information on butterfly valves, we would advise that you explore the exhaustive butterfly valve product list provided by Dombor.

Actuation Methods for Butterfly Valves

Actuation methods for butterfly valves can vary, offering different levels of control and automation.

Butterfly valves can be operated in different ways with varying degrees of control and automation to suit various applications. Below are the key types of actuation methods for butterfly valves:

Manual Actuation

This is the most basic and cost-effective approach in which a handwheel or lever is used to turn the valve stem and move the metal disc. Manual actuation works well in cases where precision control isn’t necessary due to infrequent operation. It is commonly found in small systems or applications where automation is not required, such as water supply or waste water treatment.

Electric Actuation

The electric actuators enable automated control by using an electric motor to open and close the valve. This method can precisely control flow rates easily integrated into complex control structures. Frequent operations or remote controlled ones are areas where this type would be perfect, for example industrial processes in power generation. In addition, they can be programmed specifically for certain operational requirements.

Pneumatic Actuation

This particular method relies on compressed air to make the valve work. It is quite fast and reliable, mostly used in applications that demands fail-safe position. Pneumatic actuators are widely used in chemical processing and oil and gas industries where quick and reliable valve operation is essential. They come in handy especially on hazardous environments whereby electric actuators may be risky.

Hydraulic Actuation

The hydraulic actuators use fluid that has been pressurized to operate the valve. They offer huge force output which makes them suitable for high pressure and large valves applications. Heavy industrial uses like power generation as well as refining industries have hydraulic actuators commonly available. They give robust performance and can deal with demanding operational conditions easily.

Advantages of Using Butterfly Valves

Many benefits make butterfly valves popular in different industrial applications. Here are some of the main advantages:

- Simple Design and Compact Size: The most significant feature of butterfly valves is their simple design and small size. Unlike other valves such as ball valves or gate valves, butterfly valves require less space to install. Due to their lighter weight and smaller sizes, this type of valve is favored when limited space is available for installation. This design reduces installation complexities and the number of support structures necessary which lowers the cost of installing them.

- Cost-Effectiveness: Generally, butterfly valves are more economical compared to other valve types. The simplicity in constructing them means that fewer material quantities are needed hence reduced manufacturing costs. Moreover, they have a design that enables quick and easy maintenance thus lowering downtime periods as well as maintenance expenses paid for it over its lifespan. The initial low costs combined with decrease expenses from maintenance expenditures make butterfly valves an economical solution for various industries.

- Efficient Flow Control: Butterfly valves effectively control fluid flow making them suitable across many applications. The quarter-turn operation allows for fast opening and closing giving a fine regulation on flow rate. Especially in cases where flow modulation is vital such as chemical processing, drinking water supply or waste water treatment this would be advantageous. Its metal disc construction coupled with tight valve seats ensures low pressure drop and no turbulence thereby enhancing its efficiency at controlling flows.

- Versatility and Durability: Butterfly valves are versatile and can handle multiple fluids like air, water, slurry. They come in different materials including PVC, stainless steel, rubber coated among others which make them suitable for high temperatures and pressures. High pressure ratings at elevated temperatures define what high-performance types like double offset or triple offset do best hence they provide reliable service under demanding conditions. As a result, these versatile tools have been applied throughout various sectors from fire protection and electric power generation plants.

Installation and Maintenance Pointers

Butterfly valves should be properly installed and maintained in order to be able to perform accordingly. Ensure that the valve body is correctly aligned with pipe flanges and all bolts of bolt sets are well tightened during the installation process of butterfly valve. In addition, you should monitor for any damage or debris around the valve seat, which would affect its sealing function.

Periodic servicing also involves checking whether the valve stem, metal disc and body seal have worn out or corroded. Moreover, lubricating these components extends their longevity because it guarantees smooth operation of such a valve. For butterfly valves used in high-pressure systems, regular testing and calibrations must be done to keep them working effectively as required.

Conclusion

Knowing what is a butterfly valve and how it functions has great significance for participants in industrial processes as well as piping systems. These valves bring various benefits with them ranging from simple design, cost efficiency to multipurpose capability. The performance and life span of butterfly valves on your systems can therefore be improved by selecting an appropriate type of valve and making sure that it is properly installed as well as regularly maintained.

In water supply services through waste water treatment among others, fluid flow management would not be efficient without including butterfly valves. In case you want to know more or you are just starting up on this subject matter, this tutorial gives an overview of everything about butterfly valves you need to know.