What is Ball Valve Flow Direction and Why It Matters

In order to design and install piping systems properly, the flow direction of ball valves must be considered. It simply refers to whether fluid flows toward or passes through the valve in both ways. Knowing this is crucial for effective system functioning and durability.

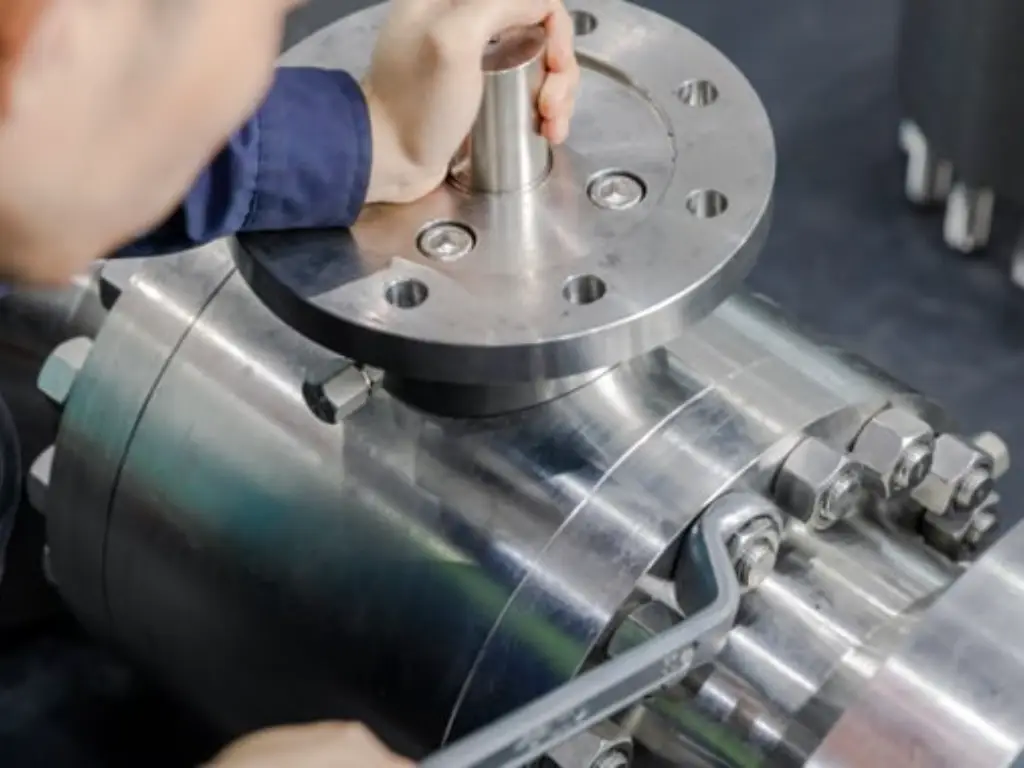

Spherical disc used by ball valves are meant to regulate the movement of either liquid or gas; hence, its flow direction can have a big impact on safety and performance of a system. Leaks, low flow rates, as well as damages to the valve or pipe can be caused by wrong flow direction, especially for unidirectional flow. A right way for flow even in closed state ensures a tight seal and enhance optimal control thus making it operate efficiently. To assist correct installation and maintenance, flow directionality is typically indicated on valve bodies with an arrow, and the lever of the right ball valve usually points to the direction of the flow, with the closed position being perpendicular to the flow direction. Installation errors may cause problems downstream requiring much expensive repairs.

Industries such as chemical manufacturing, food processing, and pharmaceuticals place great emphasis on precision and reliability. In these high-pressure systems, keeping the correct flow direction in ball valves is critical in ensuring safety and efficiency. System integrity depends on compliance with require flow directions.

Types of Ball Valves: Unidirectional vs. Bidirectional

Ball valves exist in a number of different types, each of which is designed to perform diverse functions and for various applications. An example of these types is unidirectional and bidirectional ball valves about flow direction.

Unidirectional Ball Valves

- Functionality: Permitting flow only in one direction.

- Applications: Wherever there is need to prevent backflow.

- Design: Forbidding return flows by sealing tightly.

- Types: Examples include C ball valves, V port ball valves and orbit ball valves etc.

- Usage: Integral in process integrity and safety systems that have single flow directions.

Bidirectional Ball Valves

- Functionality: Permitting flow both ways.

- Applications: Where it doesn’t matter or may change the direction of the flow.

- Design: Easy to install and versatile.

- Types: Also called control valves.

- Usage: It sacrifices strict control of flow for flexibility and convenience .

The decision on whether the system requires a unidirectional or bi-directional ball valve will depend on some factors that are unique to it . Each type has its own advantages as well as particular situations where they would be useful. Therefore, being able to differentiate between them enables one to select the most appropriate ball valve for their system, taking into consideration the direction of flow from the inlet to the outlet and vice versa. One type of bi-directional valve is the gate valve, which can be shut-off in either direction, making it a versatile option for various systems. Understanding the different types of ball valves, including gate valves, is crucial for ensuring optimum performance and efficiency.

How to Identify Ball Valve Flow Direction

For proper installation and functioning of a ball valve, it is important to first identify the direction of flow. Below are some tips that will help you determine the flow direction:

Markings on the Valve Body:

- A good number of valves have some markings on their bodies that show the direction of flow. Such marks can be arrows, text or signs that clearly indicate where the fluid is expected to move in. These indicators must be observed while installing.

Review Manufacturer’s Documentation:

- For instance, installation guides along with specification sheets, in most cases cover aspects about which way the valve directs its fluid. When it comes to good practices for installing things right and avoiding common errors this is particularly useful.

Valve Handle Position:

- The position of the valve handle can also indicate which way fluid flows through it. Therefore, some ball valves have handles that line up with flow when they’re opened. The correct direction can thus be confirmed by checking where its handle is located.

Inspecting the Valve’s Internal Design:

- Sometimes looking at the way internals have been arranged inside a valve can tell you about how fluids pass through it. So basically, for one-way sealing, unidirectional ball valves may be identified by what can be seen upon inspection from within these items.

Online Resources and Tools:

- Content generated by various manufacturers and experts within this sector also come in handy. Here, people searching videos or tutorials about identifying and explaining ball valve flow directions have all possibilities.

It is essential to correctly identify the flow pattern because once installed wrongly; leakage increases inefficiency or even damage may occur due to use of incorrect installation methods. Confirming which way water flows at layout stage saves valuable time as well as resources in future days ahead.

Correct Installation Practices for Ball Valve Flow Direction

For optimal operation and durability of ball valves, proper installation is essential. Hence, check the flow direction indicated on the valve body to ensure that it is in alignment with system requirements. Furthermore, the valve should be properly aligned with the pipeline to avoid leakage and facilitate smooth flow control; correct fittings must be used during assembly.

To prevent leaks, use appropriate tools such as appropriate size wrenches as well as Teflon tape or sealant. Also, one should read through the manufacturer’s instructions concerning how they are supposed to be installed, including what will allow for torquing and fittings made of suitable piping.

Finally, after installation always pressurize the system to expose any leakages that may exist in any part including valve connections and its body. The longevity of this device depends on regular checking for wear and tear, ease in operating it by turning its handle smoothly leading to cleaning so as to remove any dirt or debris. This ensures that a ball valve operates at an efficient level which results in a longer lifespan and maintains integrity of a system thus ensuring safety for all concerned parties.

Common Mistakes in Ball Valve Flow Direction and How to Avoid Them

Even with good intentions, some errors can occur during the installation and operation of ball valves. Here are some typical mistakes made when installing and operating ball valves:

| Common Mistake | Description | Tips to Avoid |

| Incorrect Flow Direction | Installing the valve against the intended flow direction. | Always check the valve markings and manufacturer documentation to ensure the correct flow direction. |

| Over-Tightening | Over-tightening the valve handle or fittings, causing damage to the valve body or internal components. | Use a torque wrench to apply the recommended torque and avoid excessive force. |

| Using the Wrong Type of Valve | Using a unidirectional valve in an application that requires bidirectional flow, leading to operational issues. | Ensure you select the right type of ball valve for your specific needs. |

| Ignoring Manufacturer Guidelines | Failing to follow the manufacturer’s guidelines, resulting in improper installation and potential failures. | Always refer to the provided documentation during installation and maintenance. |

| Improper Alignment | Misaligned valves causing leaks and reduced flow efficiency. | Take care to align the valve correctly with the pipeline during installation. |

| Neglecting Regular Maintenance | Skipping regular maintenance, leading to valve failures and reduced system efficiency. | Implement a routine maintenance schedule to keep the valves in good working condition. |

By avoiding these common mistakes, one is able to help ensure that their ball valve works correctly and efficiently. Properly installed/maintained- proper installation/maintenance is the key to preventing issues and preserving system integrity.

Impact of Ball Valve Flow Direction on System Efficiency

System efficiency is highly dependent on the flow direction of a ball valve. This ensures optimal control of flow, prevents backflow, reduces wear and tear, saves energy and improves safety. Proper flow direction maintains the required rate of flow and pressure in a system, protects against pollution or operational problems by one-way valves that are not properly functioning, lessens strains on valve parts so that they do not break prematurely and guarantees that the system operates economically to minimize energy consumption. For example, it is very important when dealing with hazardous materials or high pressures in order to reduce the chances of leaks and failures. The significance of understanding the impact of ball valve flow direction is essential for optimal installation & maintenance as well as peak performance, minimal downtime and reduced operating costs.

Why You Should Consider Dombor Ball Valves for Your Business and Personal Needs

Dombor, an industry leader in China’s industrial valve manufacturing sector in terms of resilience and quality, was founded in 2001. With a pledge to excellence, Dombor ensures that it delivers within ten days through its stock of over 20,000 semi-processed items. These ball valves are made from superior materials and satisfy the rigorous API and ASTM standards with temperature resistance ranging from -196℃ to 800℃. Made by employing HVOF technology, our valves give better performance and have a lifespan nearly 70% more than other finishes on the market. Every valve goes through rigorous testing such as pressure tests as well as seal tests to ensure there is no leakage. Backed by global certifications and having spent 23 years in this industry, Dombor provides unparalleled solutions in valves for your business or personal whatever needs they may be. Have faith in our dedication to quality, creativity and green growth.