Introducción

When it comes to the application of pump systems, the choice between a foot valve and a check valve can make a significant difference. Both are applied in preventing backflow and in maintaining prime but they are unique in their features. Here in this article, we will make a comparison between foot valves and check valves with the features, application and impact on the pump efficiency. Whether you are dealing with well pump, submersible pump, or any other water pump, these valves are important to know when it comes to piping system.

What Are Foot Valves?

Foot valves are a special type of one direction valves which are used in the bottom of suction line in the pump systems. These valves are very essential in the performance of the pump, especially in the well pump and submersible pump systems. Primarily, the main function of a foot valve is to maintain a suction line full of water when the pump is not running.

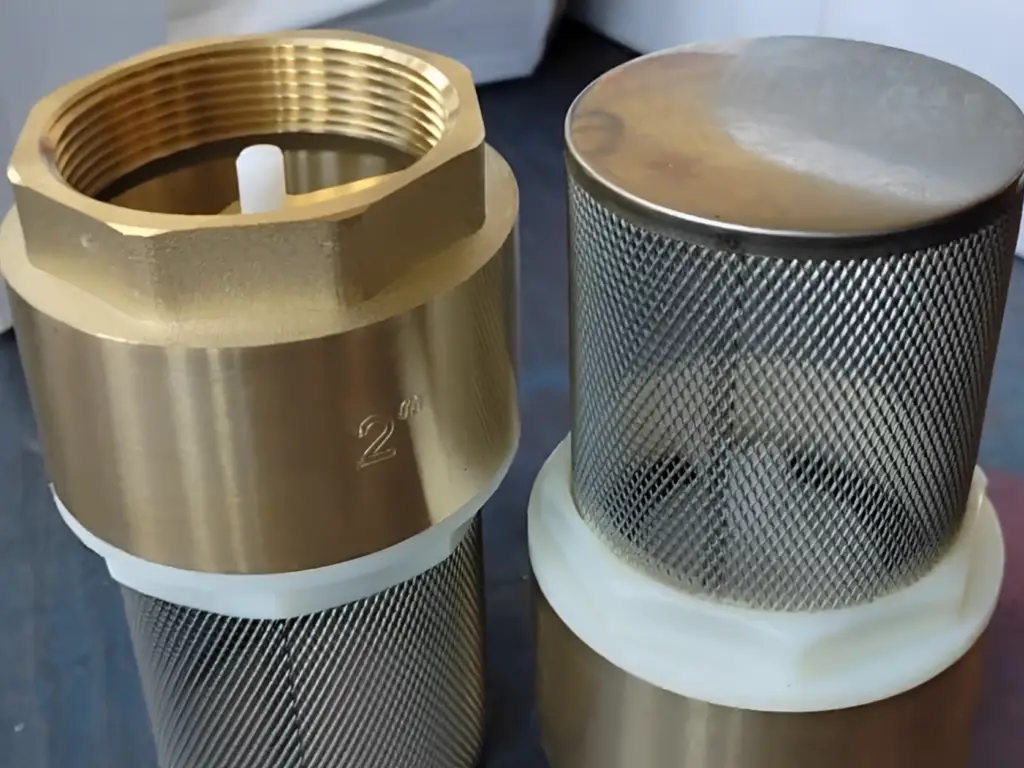

The operation of a foot valve is quite simple but very efficient. It comprises of the valve body with screen and a shut-off means which can be a flapper or a poppet. When the pump starts, it draws a suction which opens the valve and water is drawn into the suction line. When the pump ceases to operate, the valve shuts off because of gravity and the weight of the water column above the valve in order not to allow back flow and to ensure that the pump is primed.

The integrated strainer is the first barrier in the system to protect the pump from contamination by debris. Foot valves are made from brass, stainless steel or PVC depending on the application and the conditions under which they will be used.

What Are Check Valves?

Check valves, or non-return valves, are widely used in piping systems, which serve to allow fluid flows in one direction and prevent the reverse flow. While foot valves can be installed only at the bottom of the pipeline, check valves may be installed in any position along the pipeline, which gives more possibilities for the system design.

The operation of a check valve is hinged on the pressure differential across the valve. This means that when the pressure at the inlet is greater than the pressure at the outlet the valve is opened to allow the flow. When pressure is equal or even changes its direction, then the valve closes so as to prevent back flow. This self-acting feature makes check valves very important in preventing back flow and water hammer in pumps and other equipment.

Ball check valves, swing check valves and lift check valves are some of the types of check valves and each of them handles flow in its own unique way. The selection of the valve is based on the requirement of the application, pressure requirement and the type of fluid to be used. Check valves are installed in both suction and discharge lines and are therefore useful in many pump systems in different industries.

Key Differences Between Foot Valves and Check Valves

Now that we have a basic understanding of how foot valves and check valves work, let’s dive into the key differences between these two types of valves.

Now that we know about foot valves and check valves, then let us make a comparison between the two types of valves.

Design Differences: The Differences between Foot Valve and Check Valve Construction

The construction of foot valves and check valves is different from each other as well as the position where they are installed. Foot valves are normally made of a robust housing which incorporates a strainer at the base to eliminate the ingress of solids. This design may also have a poppet or flapper valve for the purpose of regulation of the flow. The integrated strainer is the prominent feature which ensures that any contamination is filtered off and does not reach the pump.

In contrast, check valves are of different types including the ball check valves, the swing check valves, and the lift check valves. Each type has its own way of regulating the unidirectional flow. Ball check valves have a ball which rises to permit flow and drops down to shut the valve and prevent back flow and are ideal for vertical installations due to its swift action.

The compact size of many check valves makes it easier to fit them into tight spaces, which is a big plus in systems with many pipes. These valve designs are less complicated than foot valves and therefore exhibit lower pressure drop thus enhancing the systems efficiency.

Foot valves are especially helpful in the region of pump prime, that is helpful for submersible pump and well pump systems. This design helps to maintain a uniform water column in the suction line, thus minimizing chances of losing prime. On the other hand, the design of check valves is quite flexible and they can be used in both low and high pressure systems.

Understanding these design differences is key when choosing between a foot valve and check valve for your specific pump application.

Installation Locations: Where to Place Foot Valves vs Check Valves

The positions of foot valves and check valves are quite different because they serve different purposes in pump systems. Foot valves are used to be installed at the bottom of the suction line and placed directly in the water supply. This position is critical to the water column in the vertical pipe and to the priming of the pump. However check valves are fairly general in design and can be installed in any part of the piping system, it can be installed at the inlet or discharge side of the system depending on the requirement of the system.

Foot valves are usually mounted on the end of the suction line and it is necessary to install them correctly. A national pipe thread (NPT) or a flanged connection is used to join the two since the size of the valve and the system it is to be placed in determines this type of connection. The foot valve should be fully submersed and placed above the bottom of the water source to avoid drawing in sediments into the system. If the valve does not have a strainer or screen, it should be installed.

Check valves, however, can be mounted in any position, either horizontally or vertically, although some types may have certain installation directions. They are usually fitted with threaded connections, flanges or wafer type between pipe flanges. When installing check valves, it is important that we consider the flow direction which is usually indicated by an arrow on the body of the check valve. It must therefore be ensured that the system is well coordinated in order to increase efficiency and to prevent back flow.

In both types of valves, there is the issue of how easily they can be reached for the purpose of maintenance and potential future replacement. Foot valves used at the bottom of deep wells are challenging to maintain while check valves are installed in easy to access parts of the piping to facilitate easy maintenance. Regardless of the valve type, proper installation following manufacturer guidelines is key to ensuring efficient operation and longevity of your pump system.

Material Considerations: Choosing the Right Valve for Your Environment

The selection of materials for foot valves and check valves has a major effect on their performance and how long they last. Let’s examine the common materials and their applications:

Foot valves are typically available in:

- De latón: The industry commonly uses brass foot valves because of their resistance to corrosion and their durability. The Copper Development Association reports that brass can tolerate temperatures up to 200°F (93°C) in the majority of plumbing applications. According to industry specifications from top valve manufacturers, these valves are intended for use in well piping systems and can effectively handle anywhere from 200 to 250 psi of pressure.

- PVC: PVC foot valves are both affordable and easy to carry. The Plastics Pipe Institute indicates that they are usually rated for temperatures up to 140°F (60°C) for continuous use. PVC valves are regularly used in irrigation systems and shallow wells at a pressure rating of around 150 psi for Schedule 40 PVC.

- Cast Iron: Cast iron foot valves are distinguished by their ability to handle high flow rates and their resiliency. According to the American Water Works Association (AWWA), cast iron valves generally function in temperatures that go up to 250°F (121°C). They find application in local water systems of municipalities as well as in industries.

Check valves come in various materials:

- Acero inoxidable: These valves furnish superior resistance against corrosion. According to the Valve Manufacturers Association, stainless steel check valves can deal with diverse temperature conditions, from cryogenics to 1000°F (538°C) for particular grades. They are regularly used in chemical processing and food industries.

- Bronze: Given their resistance to saltwater corrosion, bronze check valves are an usual selection for marine applications. Standard specifications from leading valve manufacturers show that they usually have a maximum temperature rating of about 400°F (204°C).

- CPVC: According to the Plastics Pipe Institute, PVC replacement CPVC check valves can sustain mildly higher temperatures, up to 180°F (82°C) for uninterrupted use. They are regularly used in systems that distribute hot water.

The determination of valve material is based on factors that comprise fluid type, temperature, pressure, and chemical compatibility. In a water system with a high mineral content, a brass or stainless steel valve would be the better choice because of its resistance to corrosion. When confronted with mildly hostile chemicals, PVC or CPVC might be the perfect solution.

In order to make the information more comprehensible, let’s sum up the materials discussed, their characteristics and the fields they are used in the table below.

| Material | Tipo de válvula | Max Temperature | Typical Pressure Rating | Aplicaciones comunes |

| Latón | Foot & Check | 200°F (93°C) | 200-250 psi | Well piping systems |

| PVC | Foot & Check | 140°F (60°C) | 150 psi | Irrigation, shallow wells |

| Hierro fundido | Foot | 250°F (121°C) | Varies | Municipal water systems, industrial |

| Acero inoxidable | Check | Up to 1000°F (538°C) | Varies | Chemical processing, food industry |

| Bronce | Check | 400°F (204°C) | Varies | Marine applications |

| CPVC | Check | 180°F (82°C) | Varies | Hot water distribution |

Note: Pressure ratings and temperature limits can vary by manufacturer and specific model. Always consult manufacturer specifications for precise ratings.

Application Scenarios: When to Use Foot Valves vs Check Valves

Choosing the right valve type for your system is very important in order to achieve the best results. Let’s explore the specific scenarios where foot valves and check valves shine:

Foot Valves excel in these following fields:

- Well Piping Systems: Foot valves are very useful in well installations, especially those with high suction lifts. They hold the prime position in the pump, thus guaranteeing the smooth running of the pump and minimizing the wear and tear.

- Irrigation Systems: In the farming industry, foot valves are very important in controlling the flow of water from ponds or reservoirs to irrigation pumps.

- Sump Pump Installations: Basements that are likely to flood are best served by foot valves that enable the sump pumps to start working as soon as they are required.

- Shallow Jet Pumps: These pumps depend on foot valves to keep the water flowing, especially in the domestic water supply systems where the water source is nearby.

Check valves are used in a wider range of applications because of their versatility and relatively uncomplicated construction. They’re particularly useful in:

- Municipal water supply lines: Backflow prevention is done by check valves in the public water supply systems.

- HVAC systems: They regulate the movement of coolant or refrigerant in the system, thus increasing the efficiency of the system.

- Industrial processes: In chemical plants or refineries, check valves are used to prevent the back flow of fluids which may damage certain equipment.

- Fire protection systems: They help in controlling the flow of water during floods or any other calamities.

The differences between foot valves and check valves can greatly affect the system performance, but the extent of the effects will depend on the particular system and conditions in use. When it comes to valve selection for critical systems, it is advisable to seek the opinion of experts or turn to documented case studies.

What Are the Advantages and Disadvantages of Foot Valves

Before we make a decision on which one to go for between a foot valve and a check valve we must first compare the two. First of all, we will consider the strengths and weaknesses of foot valves.

Advantages of Foot Valves

- Maintains pump prime: Foot valves prevent water from flowing back into the well or source, ensuring that the pump remains primed and ready to operate. This reduces the risk of loss of prime, which can lead to pump inefficiency and downtime.

- Built-in strainer: Foot valves are always fitted with a strainer to ensure that the debris and particles do not find their way into the pump system. This does not only lead to the protection of the well piping system but also enhances the life of the pump by reducing its usage.

- Energy and time savings: These foot valves help to avoid the need to prime the column of water in the pump, which is helpful regarding time and energy, particularly in jet pump and deep well systems.

- Corrosion resistance: The foot valves are therefore made of materials such as PVC and brass which are not easily rendered obsolete by corrosion. This guarantees long term reliability, particularly in extreme conditions.

Disadvantages of Foot Valves

- Prone to clogging: Such valves as the strainer on foot valves are very susceptible to being clogged by debris and this makes the water flow to be affected. It is suggested that the system should be cleaned at regular intervals to check that it is functioning as it should and especially in water sources with high levels of sedimentation.

- Difficult installation and maintenance: Foot valves are mounted at the discharge of a pump system and this makes it difficult to access them. It is quite apparent that foot valve replacement or repair can be quite frustrating and may require dismantling of very many lengths of pipes.

- Potential for pressure surges: If not well maintained foot valves pose a threat to the fluctuations of pressure in the system and may in the long run harm the system. To this, the solution lies in monitoring the psi levels and also makes sure that the machine is cleaned from time to time.

What Are the Advantages and Disadvantages of Check Valves

Now that we’ve explored the pros and cons of foot valves, let’s turn our attention to check valves and examine their advantages and disadvantages.

Ventajas de las válvulas antirretorno

- Prevention of backflow: The most important benefit of check valves is that they help to prevent backflow in a system. This feature assists in directing the flow of fluids in the right manner and as such, improves the system’s performance and avoids straining the pumps and the piping systems.

- Simple design: Check valves are typically designed with fewer moving parts compared to foot valves. This makes it more efficient, with fewer chances of a breakdown, and with a lower need for servicing. Due to their simple design, they can be easily installed in different piping systems.

- Versatile applications: Check valves are applied in HVAC systems, water supply and irrigation systems as well as in industrial fluid management. They are used to manage fluids ranging from water, chemical, to gases based on the conditions under which they are operated.

- Variety of types: Check valves appear in three basic types, namely the swing, the ball, and the lift check valves and can be selected depending on the operation. This versatility makes it possible to design a system that will suit specific piping and flow conditions in the system.

Desventajas de las válvulas antirretorno

- Pressure loss: The major disadvantage of check valves is that they can cause pressure drops due to the design of the valve. Some of the check valves and their installation may lead to a considerable pressure drop in the system, which is not very good for the system’s performance.

- Potential for valve wear: Check valves are usually very dependable, but they can fail after a period of use, particularly in high velocity systems. It is thus prudent to look for the condition of the valve from time to time so that any incidence of mishap may be prevented.

- Installation challenges: Check valves should be installed correctly in order to work as expected. Incorrect installation can lead to operational issues, including flow restrictions or unintended backflow. One must make sure that the device is properly positioned and aligned in the right manner in order to function properly.

Making the Right Choice: Factors to Consider When Selecting Between Foot Valves and Check Valves

In the selection process of foot valves versus check valves, a number of important factors are at work. Let’s explore the critical considerations that can help you make an informed decision:

System Configuration and Suction Lift

The design of your piping system is important. For systems of well piping with considerable suction lift, foot valves are usually essential. When working with a lengthy column of water, they are particularly skilled at preserving prime in pumps. On another note, check valves have greater flexibility and can be organized in several different ways, which renders them appropriate for a greater selection of system configurations.

Maintenance Accessibility

Think how easily you can access the valve for maintenance or for the need to replace it. Found at the bottom of suction lines, foot valves are often difficult to access, especially in wells of considerable depth. There can be an increase in downtime throughout the period of repairs. Normally found in an inline position, check valves are usually engineered to allow maintenance access that might assist in minimizing ongoing operational costs.

Characteristics of Flow and the Loss of Pressure

Different valve designs have an effect on both flow dynamics and pressure loss. Foot valves, which accompany strainers, usually demonstrate a greater level of flow resistance than many check valves. This can result in pump efficiency, particularly in systems at the edge of their performance limits. When the main issue is reducing pressure loss, a correctly designed check valve could be the better option.

Environmental Factors

The operating environment is important in the selection of valves. If your application faces debris or sediment issues, particularly in open water sources, foot valves fitted with strainers will give additional protection for your pump. In cleaner, closed systems, the basic design of check valves could be enough and might deliver superior long-term reliability.

Consideraciones económicas

While the costs at the beginning are key, it’s just as important to examine the whole cost of ownership over time. Although foot valves have a greater initial cost, they could save money in the long haul by lessening pump wear in particular applications. Unlike many other valves, check valves usually incur reduced initial and maintenance costs, which could yield greater value for fundamental systems.

Thinking strategically about these features allows you to pick the valve type that exceedingly matches your particular requirements, ultimately securing higher pump efficiency and system performance.

Spotlight on Dombor: A Leading Industrial Valve Manufacturer

It is important to choose the right valve for the system. Dombor, China’s leading industrial valve producer since 2001, provides check valves. They guarantee the high quality of the products through the quality control measures such as the low-temperature impact test at 60°C and the 100% performance test. Dombor offers a 24-month warranty and has strong after-sales service support. To get the best valve solutions that will improve the performance of your system, contact Dombor hoy.